100% Original Precision Die Cast - HIGH-PERFORMANCE & TAILOR-MADE MINERAL CASTING TECHNOLOGY – ZHONGHUI

100% Original Precision Die Cast - HIGH-PERFORMANCE & TAILOR-MADE MINERAL CASTING TECHNOLOGY – ZHONGHUI Detail:

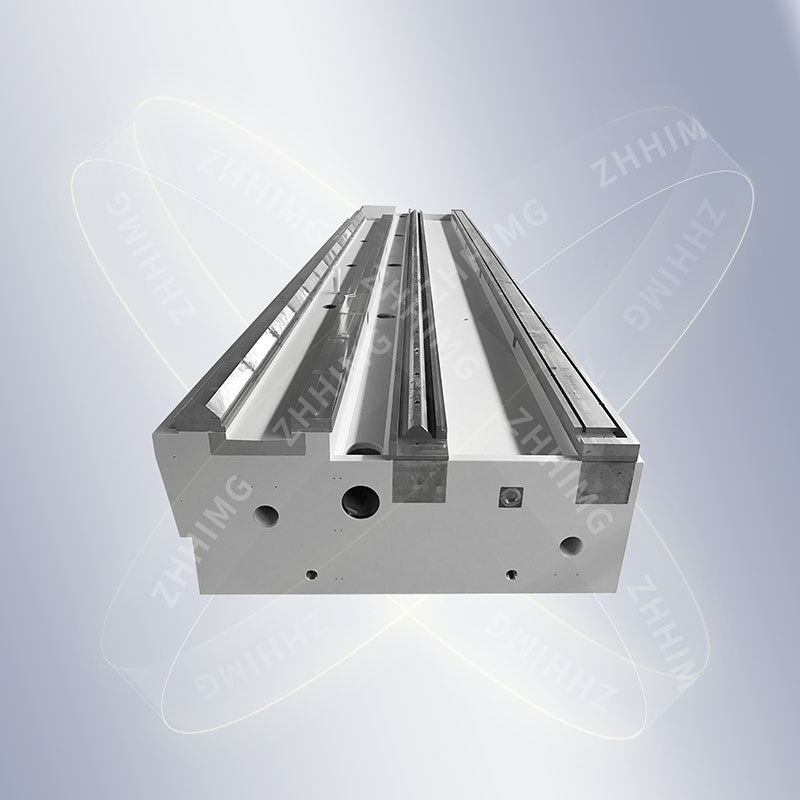

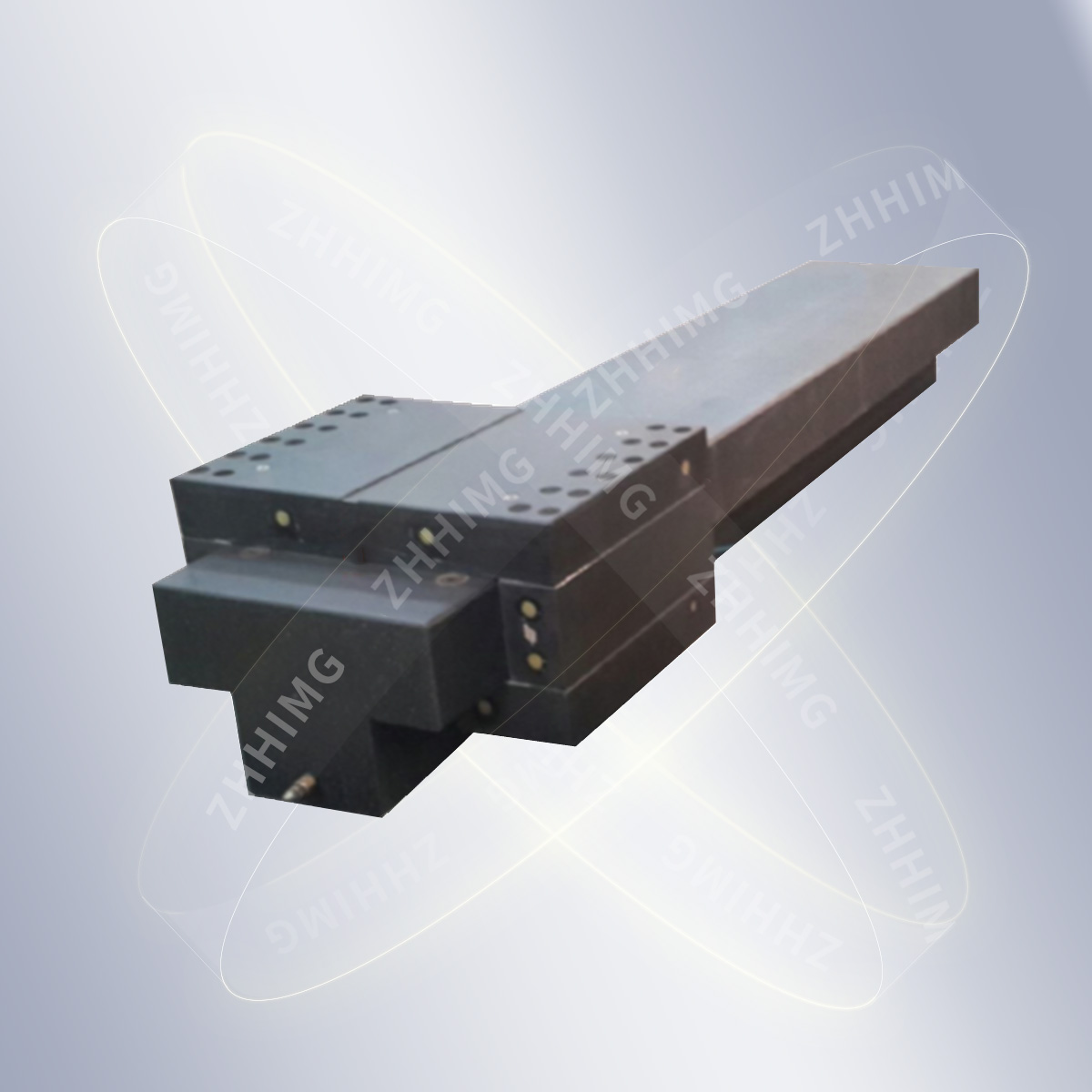

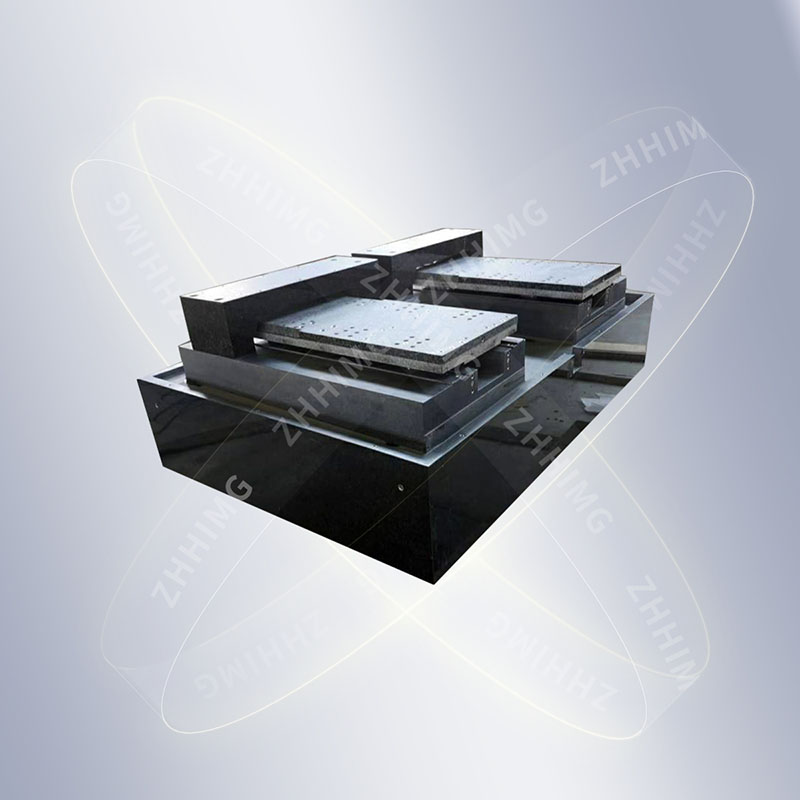

The mineral composite material and its machine tool components have been industrialized. Mineral composite material is a new type of composite material formed by modified epoxy resin and other materials as binders, granite and other mineral particles as aggregates, and reinforced by reinforcing fibers or nanoparticles. Mineral composite products are often called For mineral castings (Mineral Castings).

Mineral composite materials have become a replacement for traditional metals or an ideal material for natural mineral materials due to their excellent vibration damping (shock absorption), high dimensional accuracy and shape integrity, low thermal conductivity and moisture absorption, excellent corrosion resistance and magnetic resistance, etc.

The popularity of ZHHIMG® is essentially due to its outstanding damping qualities in comparison to gray cast iron and welded constructions. This ensures the machine bed structure has greater dynamic stability in ultra-fast and high-precision production machinery. Comparative measurements of the logarithmic decrement as a damping parameter show that mineral casting has a material damping capacity that is eight to ten times greater than metal materials.

|

Model |

Details |

Model |

Details |

|

Size |

Custom |

Application |

CNC, Laser, CMM… |

|

Condition |

New |

After-sales Service |

Online supports, Onsite supports |

|

Origin |

Jinan City |

Material |

Mineral Casting |

|

Color |

Black/White |

Brand |

ZHHIMG |

|

Precision |

0.001mm |

Weight |

≈2.5g/cm3 |

|

Standard |

DIN/ GB/ JIS… |

Warranty |

1year |

|

Packing |

Export Plywood CASE |

After Warranty Service |

Video technical support, Online support, Spare parts, … |

|

Payment |

T/T, L/C… |

Certificates |

Inspection Reports/ Quality Certificate |

|

Keyword |

Ceramic Machine Base; Ceramic Mechanical Components; Ceramic Machine Parts; Precision Ceramic |

Certification |

CE, GS, ISO, SGS, TUV… |

|

Delivery |

EXW; FOB; CIF; CFR; DDU; CPT… |

Drawings’ format |

CAD; STEP; PDF… |

Further benefits of ZHHIMG® mineral casting:

● Low thermal conductivity for high thermal stability

● High isotropy and homogeneity prevent load-related deformation of machine beds

● High media resistance

● Unconventional bed and variant structures thanks to flexible modeling, non-cutting replication, and innovative bonding technology

● Lower machine cover/cladding costs thanks to high surface and design functionality

● Resource-saving, almost CO2-free production (cold cast), environmentally friendly disposal and recycling contribute to a more sustainable and environmentally friendly industrial production

The numerous advantages of non-cutting machine beds made of mineral casting can now also be used for larger precision surfaces:

● Unbeatable cost-efficiency, especially for medium to large quantities, as there is no costly use of machining equipment

● Entire process is completed by us in-house – replicating in a climate-controlled workshop at 20°C, no external processors or transport required

● High reliability due to lack of influence from machines or tools

● Only a small number of milling and grinding contractors can reliably provide such high-precision results in these dimensions; the new replication technology eliminates any dependency on these service providers (e.g. fluctuating capacities) and thus ensures just-in-time delivery

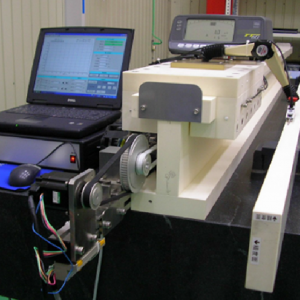

We use various techniques during this process:

● Optical measurements with autocollimators

● Laser interferometers and laser trackers

● Electronic inclination levels (precision spirit levels)

1. Documents together with products: Inspection reports + Calibration reports(measuring devices) + Quality Certificate + Invoice + Packing List + Contract + Bill of Lading(or AWB).

2. Special Export Plywood Case: Export fumigation-free wooden box.

3. Delivery:

|

Ship |

Qingdao port |

Shenzhen port |

TianJin port |

Shanghai port |

… |

|

Train |

XiAn Station |

Zhengzhou Station |

Qingdao |

… |

|

|

Air |

Qingdao Airport |

Beijing Airport |

Shanghai Airport |

Guangzhou |

… |

|

Express |

DHL |

TNT |

Fedex |

UPS |

… |

1. We will offer technical supports for assembly, adjustment, maintain.

2. Offering the manufacturing &inspection videos from selecting material to delivery, and customers can control and know every detail at anytime anywhere.

Product detail pictures:

Related Product Guide:

Adhering into the basic principle of "quality, assistance, effectiveness and growth", we have attained trusts and praises from domestic and worldwide client for 100% Original Precision Die Cast - HIGH-PERFORMANCE & TAILOR-MADE MINERAL CASTING TECHNOLOGY – ZHONGHUI , The product will supply to all over the world, such as: Muscat, Argentina, Portugal, Our products are mainly exported to Europe, Africa, America, the Middle East and Southeast Asia and other countries and regions. We have enjoyed a great reputation among our customers for quality products and good services.We would make friends with businessmen from at home and abroad, following the purpose of "Quality First, Reputation First, the Best Services."

QUALITY CONTROL

If you can’t measure something, you can’t understand it!

If you can’t understand it.you cant control it!

If you can’t control it, you can’t improve it!

More information please click here: ZHONGHUI QC

ZhongHui IM, your partner of metrology, help you succeed easily.

Our Certificates & Patents:

Certificates and Patents are an expression of a company’s strength. It’s society’s recognition of the company.

More certificates please click here: Innovation & Technologies – ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (zhhimg.com)

Material Analysis (Physical Properties):

1. Granite Material from Mines

1. Granite Material from Mines

2. Ceramic Material

3. Mineral Casting

4. Precision Metal

5. Precision Glass

6. UHPC

7. Carbon fiber

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!