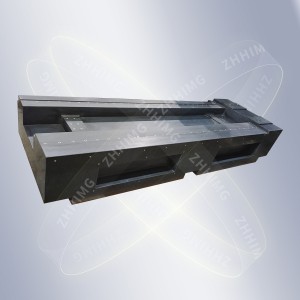

Custom Granite Gantry Frame & Ultra-Precision Machine Base

This custom-designed frame leverages the superior material science and manufacturing expertise of ZHHIMG®, placing it at the forefront of ultra-precision components.

1. Material Superiority: ZHHIMG® Black Granite

We utilize our proprietary ZHHIMG® Black Granite, renowned globally for its exceptional physical properties that outperform many common European and American granite variants.

● Exceptional Density: Boasting a high density of approximately 3100 kg/m³, our granite minimizes porosity and maximizes thermal inertia, providing superior resistance to environmental absorption and temperature gradients.

● Low Thermal Expansion: Granite's naturally low Coefficient of Thermal Expansion (CTE) ensures that the critical dimensions of the gantry—its parallelism and perpendicularity—remain stable across typical operating temperature ranges, minimizing thermal drift errors that plague metal frames.

● High Damping Capacity: The intrinsic crystalline structure of the granite rapidly absorbs and dissipates mechanical vibrations (damping), effectively creating a vibration-insulated platform for sensitive components like sensors, optics, and linear motors mounted within the frame.

2. Structural Precision and Manufacturing Capability

This complex component demonstrates the world-class processing capacity required for ultra-precision integration.

● Monolithic and Modular Design: The base structure features intricate internal cutouts and T-slots (likely for cable management, weight reduction, or internal air bearing applications), manufactured on equipment capable of processing monolithic components up to 100 tons, ensuring maximum rigidity and minimal structural joints.

● Certified Geometric Accuracy: The base and vertical supports are manufactured and verified in our 10,000 m² temperature- and humidity-controlled clean rooms, ensuring geometric tolerances meet or exceed the most stringent international standards (including DIN, ASME, and JIS).

● Precision Insertion and Assembly: Note the presence of numerous threaded inserts (often stainless steel or aluminum) visible around the base and vertical posts. These are installed with micron-level positional accuracy, ready for the direct assembly of air bearings, linear guides, and custom fixtures.

3. Unmatched Finishing and Traceability

Our products embody the principle that "The precision business can't be too demanding."

● Hand-Lapped Surfaces: The critical mounting surfaces for the gantry's bridge and base are finished by our master technicians—who often possess over 30 years of experience—achieving flatness and straightness tolerances at the sub-micron or nanometer level using manual lapping techniques.

● Metrology Validation: Every critical dimension and geometric relationship is verified using the most advanced equipment, including Reinshaw Laser Interferometers and Swiss WYLER electronic levels, with calibration certificates traceable back to national metrology institutes.

|

Model |

Details |

Model |

Details |

|

Size |

Custom |

Application |

CNC, Laser, CMM... |

|

Condition |

New |

After-sales Service |

Online supports, Onsite supports |

|

Origin |

Jinan City |

Material |

Black Granite |

|

Color |

Black / Grade 1 |

Brand |

ZHHIMG |

|

Precision |

0.001mm |

Weight |

≈3.05g/cm3 |

|

Standard |

DIN/ GB/ JIS... |

Warranty |

1year |

|

Packing |

Export Plywood CASE |

After Warranty Service |

Video technical support, Online support, Spare parts, Field mai |

|

Payment |

T/T, L/C... |

Certificates |

Inspection Reports/ Quality Certificate |

|

Keyword |

Granite Machine Base; Granite Mechanical Components; Granite Machine Parts; Precision Granite |

Certification |

CE, GS, ISO, SGS, TUV... |

|

Delivery |

EXW; FOB; CIF; CFR; DDU; CPT... |

Drawings’ format |

CAD; STEP; PDF... |

The stability and geometric integrity provided by this custom granite frame are essential for:

● Semiconductor Equipment: Wafer inspection and processing stages, dicing machine bases.

● Metrology Systems: High-accuracy Coordinate Measuring Machines (CMM) and specialized optical measurement benches.

● Laser Processing: Bases for Femtosecond and Picosecond laser micromachining systems requiring zero vibration.

● High-Speed Automation: Ultra-stable frames for large XY linear motor stages and high-speed PCB drilling machines.

We use various techniques during this process:

● Optical measurements with autocollimators

● Laser interferometers and laser trackers

● Electronic inclination levels (precision spirit levels)

1. Documents together with products: Inspection reports + Calibration reports(measuring devices) + Quality Certificate + Invoice + Packing List + Contract + Bill of Lading(or AWB).

2. Special Export Plywood Case: Export fumigation-free wooden box.

3. Delivery:

|

Ship |

Qingdao port |

Shenzhen port |

TianJin port |

Shanghai port |

... |

|

Train |

XiAn Station |

Zhengzhou Station |

Qingdao |

... |

|

|

Air |

Qingdao Airport |

Beijing Airport |

Shanghai Airport |

Guangzhou |

... |

|

Express |

DHL |

TNT |

Fedex |

UPS |

... |

1. We will offer technical supports for assembly, adjustment, maintain.

2. Offering the manufacturing &inspection videos from selecting material to delivery, and customers can control and know every detail at anytime anywhere.

QUALITY CONTROL

If you can’t measure something, you can’t understand it!

If you can’t understand it.you cant control it!

If you can’t control it, you can’t improve it!

More information please click here: ZHONGHUI QC

ZhongHui IM, your partner of metrology, help you succeed easily.

Our Certificates & Patents:

ISO 9001, ISO45001, ISO14001, CE, AAA Integrity Certificate, AAA-level enterprise credit certificate…

Certificates and Patents are an expression of a company’s strength. It’s society’s recognition of the company.

More certificates please click here: Innovation & Technologies – ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (zhhimg.com)