In the field of coating equipment display, granite has become a highly regarded material choice due to its unique physical properties. However, it is not perfect. The following will comprehensively analyze the advantages and disadvantages of granite in display coating equipment, providing a clear reference for practitioners.

I. The significant advantages of granite in showcasing coating equipment

1. Excellent stability

Granite has a high density and dense structure, which can effectively resist external vibrations and impacts. During the operation of the coating equipment, it can maintain the stability of the equipment, avoid problems such as uneven spraying and inconsistent coating thickness caused by vibration, and ensure the high precision and quality of the display coating.

2. Excellent corrosion resistance

Granite is mainly composed of minerals such as quartz and feldspar. It has stable chemical properties and strong resistance to chemical substances like acids and alkalis. During the coating process, it is inevitable to come into contact with various chemical agents such as paints and solvents. The granite base can be used for a long time without corrosion, extending the service life of the equipment and reducing maintenance costs.

3. High-precision surface

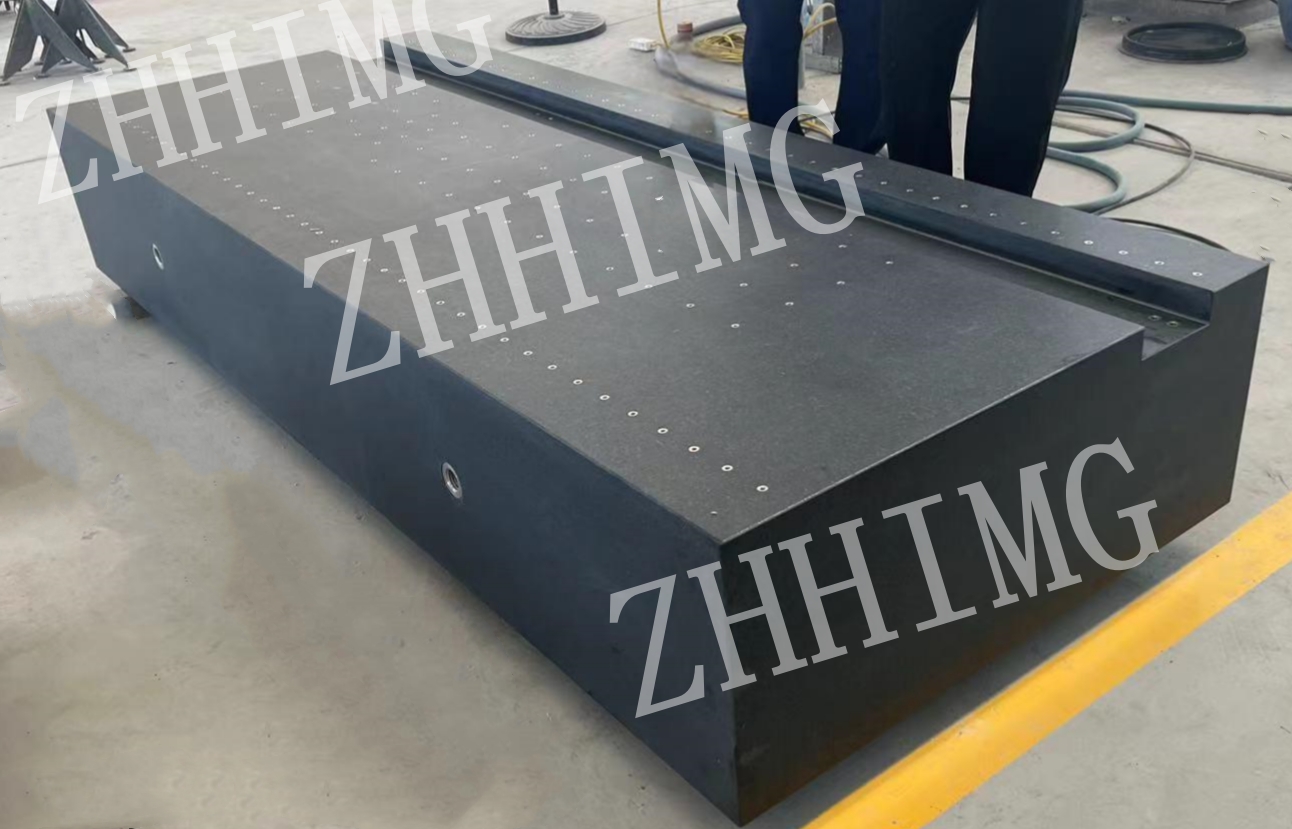

Through advanced processing techniques, granite can be ground and polished to extremely high flatness and smoothness. This high-precision surface can provide an accurate installation reference for coating equipment, ensuring the relative position accuracy between equipment components and thereby enhancing the coating effect.

4. Strong thermal stability

The coefficient of thermal expansion of granite is extremely low. In an environment with large temperature variations, its dimensional changes are negligible. This feature enables the display coating equipment to maintain a stable working state under different temperature conditions, and the coating accuracy will not be affected by thermal expansion and contraction.

Ii. Limitations of Granite in the Application of Display Coating Equipment

1. It is relatively heavy

Granite has a high density, which leads to an increase in the overall weight of the equipment. This not only increases the difficulty of transporting and installing the equipment, raising the transportation cost, but also may put forward higher requirements for the load-bearing capacity of the building ground. If the ground of the exhibition venue cannot bear it, additional reinforcement treatment is also required.

2. Relatively high price

From mining, processing to transportation, the cost of granite is relatively high. Especially the granite components that have undergone high-precision processing are even more expensive. For enterprises or projects with limited budgets, it may bring considerable cost pressure.

3. It is difficult to process

Granite is highly hard. When undergoing secondary processing such as drilling and slotting, professional equipment and tools are required, resulting in a long processing cycle and high processing costs. Moreover, problems such as chipping and cracking are prone to occur during the processing, which will affect the processing quality and the yield of finished products.

4. Difficulty in repair

Once the surface of granite shows signs of wear, scratches or damage, the repair is rather difficult. Minor damage can be treated by grinding and polishing, but if the damage is severe, components often have to be replaced, resulting in high maintenance costs and time costs.

Understanding the advantages and disadvantages of granite in display coating equipment can help enterprises make reasonable choices based on their own needs and actual situations. Whether pursuing high precision and stability or considering cost and maintenance convenience, only after weighing the pros and cons can the equipment achieve its maximum efficiency and the best effect of display coating be achieved

Post time: Jun-13-2025