In today's era of rapid technological development, 8K panel inspection equipment is crucial for ensuring the high quality of display screens. When such equipment is in operation, it has extremely high requirements for the stability of the detection environment. Any slight vibration may cause deviations in the detection results. Granite, due to its unique physical properties, has become an ideal material in the anti-vibration scheme of 8K panel inspection equipment.

The characteristic advantages of granite

Granite is hard in texture and has extremely high rigidity. Its internal structure is compact, and the bonding force between crystals is strong, which can effectively resist the impact and deformation of external forces. This high rigidity makes the granite less likely to undergo significant deformation when bearing the weight of the equipment and dealing with possible vibrations, providing a stable foundation support for the detection equipment.

Meanwhile, granite also has excellent damping properties. Damping refers to the ability of an object to consume energy and reduce the amplitude of vibration during its vibration process. The damping characteristics of granite stem from its complex internal mineral structure and tiny pores. When vibration is transmitted to granite, these structures and pores can convert the vibration energy into other forms of energy such as thermal energy, thereby rapidly attenuating the vibration. Compared with other materials, granite has a more significant damping effect and can greatly reduce the impact of external vibrations on detection equipment.

The application forms of granite in anti-vibration schemes

As the equipment base

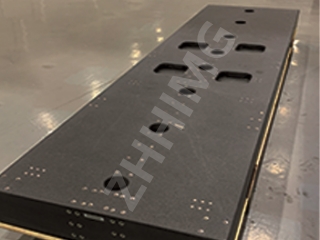

Making the base of the inspection equipment from granite is a common way to prevent vibration. Through meticulous processing, the surface flatness of the granite base reaches an extremely high precision standard, ensuring that the equipment can be stably placed after installation. Due to granite

The base can effectively isolate the vibration transmitted from the ground, reduce the interference of vibration on the precision components inside the equipment, and make the detection process more stable and reliable. For instance, in some high-end 8K panel inspection equipment, the use of granite bases several centimeters thick, combined with precise installation techniques, can reduce the impact of ground vibration to an almost negligible level, thereby ensuring the accuracy and repeatability of the inspection results.

It is used in conjunction with vibration isolation components

To further enhance the anti-vibration effect, granite often works in conjunction with various vibration isolation components. Installing rubber vibration isolation pads under the granite base is a simple and effective method. Rubber has excellent elasticity and damping properties, capable of absorbing and buffering the vibration energy from the ground. When the vibration is transmitted to the rubber vibration isolation pad, its elastic deformation partially converts the vibration energy into the thermal energy inside the rubber. Meanwhile, the damping effect of the rubber also suppresses the continuous transmission of the vibration. In this way, after the initial vibration isolation by the rubber vibration isolation pads, the remaining minor vibrations are further attenuated by the granite base, which greatly improves the performance of the entire anti-vibration system.

In addition, the combination of the air flotation vibration isolation system and granite has also been widely applied in some high-precision detection equipment. The air flotation vibration isolation system isolates vibrations by forming a high-pressure air film between the granite base and the ground, taking advantage of the compressibility of air. The granite base, supported by the air flotation system, is almost in a frictionless suspended state and can extremely effectively isolate low-frequency vibrations. This combination method is particularly suitable for the 8K panel inspection process that is extremely sensitive to vibration, such as the high-precision optical inspection section. It can ensure that the inspection equipment operates in an extremely stable environment and achieve precise detection of minute defects on the panel.

Summary of the advantages of granite anti-vibration schemes

Granite has many advantages in the anti-vibration scheme of 8K panel inspection equipment. From the perspective of cost-effectiveness, granite, as a natural material, has a wide range of sources and a relatively reasonable price. Compared with some high-end synthetic materials or complex anti-vibration devices, using granite to build an anti-vibration system can effectively control costs while ensuring the anti-vibration effect.

In terms of stability and durability, the high rigidity and excellent physical and chemical stability of granite enable it to maintain stable performance for a long time. It is not easily affected by environmental factors such as temperature and humidity to deform or have its performance decline, and can provide a long-lasting and reliable anti-vibration guarantee for detection equipment. Even during long-term and high-intensity use, the granite anti-vibration system can still maintain excellent anti-vibration performance, reducing the frequency of equipment failures and maintenance caused by vibration issues, and enhancing the overall service life and operational efficiency of the equipment.

In conclusion, granite, with its unique properties, plays an irreplaceable and significant role in the anti-vibration scheme of 8K panel inspection equipment, providing a solid and reliable foundation for ensuring the high-precision operation of the inspection equipment and high-quality inspection results

Post time: May-19-2025