In the field of 8K panel inspection equipment, the high-precision inspection requirements have put forward strict demands on the stability of the equipment. Vibration, as a key factor affecting the detection accuracy, must be effectively controlled. ZHHIMG granite, with its outstanding physical properties, has demonstrated unique advantages in the anti-vibration solution of 8K panel inspection equipment, providing a reliable guarantee for achieving high-precision inspection.

The characteristic advantages of ZHHIMG granite

ZHHIMG granite has undergone a long natural aging process, resulting in a uniform organizational structure and almost complete elimination of internal stress, thus possessing excellent dimensional stability. Its linear expansion coefficient is extremely small. Compared with steel or cast iron, it is minimally affected by temperature changes and can maintain a stable shape at different environmental temperatures. This is crucial for temperature-sensitive 8K panel inspection equipment. The hardness of granite is comparable to that of high-quality quenched steel, and it has excellent wear resistance. It can effectively resist wear during long-term use and ensure the long-term stability of equipment accuracy. In addition, granite has excellent acid and alkali resistance, is not corroded by acidic or alkaline substances, requires no additional anti-rust treatment, is easy to maintain and has a long service life. It is not restricted by constant temperature conditions and can maintain high precision in a normal temperature environment, which provides convenience for the wide application of 8K panel inspection equipment.

Vibration issues of 8K panel detection equipment

The 8K panel inspection equipment has extremely high requirements for inspection accuracy. Any slight vibration may cause deviations in the inspection results. In the actual working environment, equipment may be affected by various factors such as ground vibrations, vibrations generated by the equipment's own operation, and disturbances from the surrounding environment. Ground vibrations may originate from the daily activities of buildings, the vibrations of nearby traffic, etc. These vibrations are transmitted to the equipment through the ground, interfering with the detection process. The mechanical operation of the equipment itself, such as the rotation of the motor and the movement of transmission components, can also generate vibrations. If not effectively controlled, it will directly affect the detection accuracy. In addition, factors such as air flow changes and personnel movement in the surrounding environment may also cause slight vibrations of the equipment, which can interfere with the detection of the 8K panel.

ZHHIMG Granite Anti-vibration Scheme Design

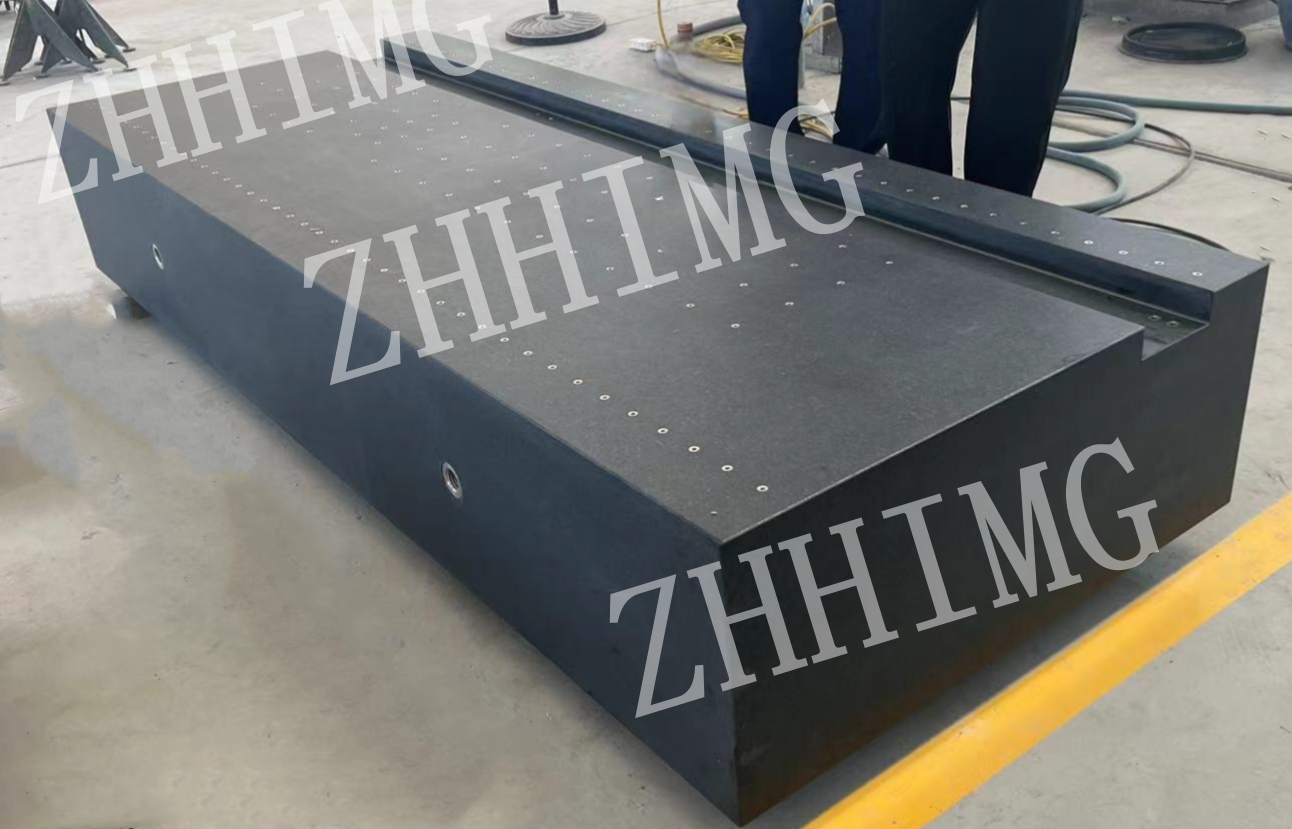

Equipment Base Design

The ZHHIMG granite is adopted as the base of the 8K panel inspection equipment. By taking advantage of its high rigidity and excellent vibration absorption performance, it effectively isolates the conduction of ground vibrations. The mass of the granite base is relatively large, which can enhance the overall stability of the equipment and reduce the impact of external vibrations on the equipment. Through precise processing techniques, the flatness and accuracy of the base surface are ensured, providing a solid and reliable foundation for the installation of the equipment.

Construction of vibration isolation system

Special vibration isolation devices, such as air spring vibration isolators and rubber vibration isolation pads, are set between the granite base and the main body of the equipment. Air spring vibration isolators can automatically adjust their stiffness according to the weight and vibration conditions of the equipment, providing efficient vibration isolation effects and effectively reducing the vertical vibration transmission. Rubber vibration isolation pads have excellent elasticity and damping characteristics, which can absorb and disperse the vibration energy in the horizontal direction, further enhancing the vibration isolation performance. By rationally combining and using these vibration isolation devices, a comprehensive vibration isolation system is constructed to minimize the impact of vibration on the equipment to the greatest extent.

Component connection optimization

Inside the equipment, special flexible connection methods are adopted for the connection of key components, such as using elastic couplings, damping pads, etc. Elastic couplings can compensate for installation errors between components and reduce vibration transmission caused by misalignment of components. Damping pads can play a role in buffering and vibration reduction at the connection points of components, effectively reducing the transmission of vibrations generated during the operation of the equipment between components, ensuring the stable operation of each component, and improving the detection accuracy.

The implementation and effect evaluation of the anti-vibration plan

When implementing the ZHHIMG granite anti-vibration scheme, construction and installation must be carried out strictly in accordance with the design requirements. The processing accuracy of the granite base, the installation position and parameter adjustment of the vibration isolation device, etc. all need to be precisely controlled to ensure the effectiveness of the plan. After the equipment installation is completed, the vibration condition of the equipment is comprehensively inspected through professional vibration testing instruments to evaluate the implementation effect of the anti-vibration plan. The test results show that the anti-vibration scheme adopting ZHHIMG granite can significantly reduce the vibration level of the 8K panel detection equipment, control the vibration amplitude within an extremely small range, effectively improve the detection accuracy, and meet the high-precision requirements of 8K panel detection.

To sum up, ZHHIMG granite has irreplaceable advantages in the anti-vibration scheme of 8K panel inspection equipment. Through reasonable scheme design and precise implementation, a stable and reliable working environment can be provided for 8K panel inspection equipment, effectively promoting the development and progress of 8K panel inspection technology.

Post time: May-22-2025