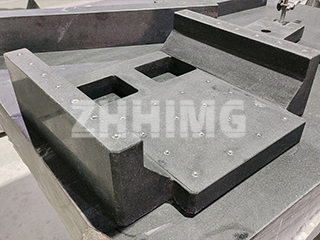

As a professional manufacturer of precision measuring tools, ZHHIMG has been dedicated to the R&D, production and maintenance of granite mechanical components for decades. Our products have won high recognition from customers worldwide, especially in high-precision testing fields. If you are looking for reliable granite mechanical components, this article will help you understand their application scope, technical advantages and customization services.

1. Wide Application Fields of Granite Mechanical Components

Granite mechanical components are essential precision benchmark tools, widely used in various testing and inspection scenarios. Their unique material properties and customizable design make them suitable for multiple industries:

- Electronics Industry: Used in precision testing of electronic components, ensuring the accuracy of micro – parts assembly.

- Mechanical Engineering: Replaces traditional cast iron plates by adding holes (through holes, threaded holes) and grooves (T – slots, U – slots) on the surface, suitable for mechanical parts inspection and assembly positioning.

- Light Industry & Manufacturing: Applied in product flatness measurement, quality control and production line testing, improving production efficiency and product quality.

- Laboratory & Research Institutions: Ideal for laboratory experiments and high – precision testing projects. Many well – known laboratories choose our products because of their stable performance and high accuracy.

2. Precision Grades & Environmental Requirements

According to Chinese national standards, granite mechanical components are divided into three precision grades: Grade 2, Grade 1 and Grade 0. Different grades have different application environments:

- Grade 2 & Grade 1: Can be used in normal temperature environments, meeting the needs of general precision testing.

- Grade 0: Requires a constant temperature workshop (20 ± 2℃). Before testing, it should be placed in a constant temperature room for 24 hours to ensure measurement accuracy.

Our team will recommend the most suitable precision grade based on your specific application scenarios and accuracy requirements, ensuring optimal performance of the products.

3. Superior Material Properties of Granite Mechanical Components

The stone used for ZHHIMG’s granite mechanical components is extracted from rock formations with hundreds of millions of years of natural aging, which gives the products excellent stability. Compared with other materials, it has obvious advantages:

| Material Type | Density Range | Key Advantages |

|---|---|---|

| ZHHIMG Granite Components | 2.9~3.1g/cm³ | High density, stable shape, no precision change due to temperature difference |

| Decoration Granite | 2.6~2.8g/cm³ | Low density, mainly for decoration, not suitable for precision testing |

| Concrete | 2.4~2.5g/cm³ | Low strength, easy to deform, cannot be used for precision tools |

4. Customized Granite Air – Floated Platforms

In addition to standard granite mechanical components, ZHHIMG also provides customized granite air – floated platforms, which are widely used in high – precision measurement equipment:

- Structure Design: The air – floated platform is a two – degree – of – freedom gantry measurement device. The moving slider is installed on the granite guide rail, and the slider is equipped with porous air – floated bearings.

- Precision Guarantee: High – pressure gas is filtered by an air filter and stabilized by a precision pressure reducing valve, ensuring frictionless operation of the slider on the guide rail.

- Processing Technology: The surface of the granite platform is ground for many times. During the processing, an electronic level is used for repeated measurement and grinding, which significantly improves the flatness. The flatness difference between constant temperature and normal temperature environments is only 3μm.

5. Why Choose ZHHIMG Granite Mechanical Components?

- Rich Experience: Decades of production experience in granite platforms, mature design, production and maintenance systems.

- High Quality: Strict material selection and precision processing, meeting the needs of high – precision testing fields.

- Customization Service: According to the customer’s application environment and accuracy requirements, customize the size, holes and grooves of the products.

- Global Service: Provide timely after – sales service and technical support for customers around the world.

If you want to know more about the application of granite mechanical components in your industry, or need a customized solution, please feel free to contact us for a quote. Our professional team will reply to you within 24 hours!

Post time: Aug-27-2025