In the quiet halls of calibration laboratories, semiconductor cleanrooms, and aerospace metrology suites, a silent revolution is underway. It’s not driven by software or sensors alone—but by the very materials that form the foundation of measurement itself. At the forefront of this shift are advanced ceramic measuring instruments, including the ultra-stable ceramic air straight ruler and the exceptionally rigid high precision silicon-carbide (Si-SiC) parallelepiped and square. These aren’t just tools; they’re enablers of a new era where stability, repeatability, and thermal neutrality are non-negotiable.

For over half a century, black granite dominated precision metrology. Its natural damping, low thermal expansion, and excellent flatness made it the go-to material for surface plates, squares, and straight edges. Yet as industries push into sub-micron and even nanometer-scale tolerances—especially in semiconductor lithography, space optics, and quantum computing—granite’s limitations have become increasingly apparent. It’s heavy, susceptible to micro-chipping under repeated contact, and, despite its reputation, still exhibits minute long-term creep under load or environmental fluctuation.

Enter engineered ceramics: not the brittle pottery of everyday imagination, but dense, homogeneous, high-performance materials forged under extreme heat and pressure. Among these, two classes stand out for metrology applications: high-purity alumina (Al₂O₃) and reaction-bonded silicon carbide (Si-SiC). While both offer dramatic improvements over traditional materials, they serve distinct roles—and together, they represent the cutting edge of what’s possible in dimensional metrology.

Take the ceramic air straight ruler, for instance. Designed for use with air-bearing stages or optical interferometers, this instrument demands near-perfect straightness, minimal mass, and zero thermal drift. Alumina-based ceramic rulers—machined to flatness and straightness within ±0.5 µm over 500 mm and polished to surface roughness below Ra 0.02 µm—deliver exactly that. Their low density (~3.6 g/cm³) reduces inertia in dynamic measurement systems, while their non-magnetic, non-conductive nature eliminates interference in sensitive electronic or magnetic environments. In wafer inspection tools or laser tracker calibration setups, where even a micron of bow can skew results, the ceramic air straight ruler provides a stable, inert reference that remains true across temperature swings and operational cycles.

But when ultimate stiffness and thermal conductivity are required—such as in space telescope mirror alignment or high-power laser cavity metrology—engineers turn to high precision silicon-carbide (Si-SiC) parallelepiped and square components. Si-SiC is among the stiffest materials known, with a Young’s modulus exceeding 400 GPa—more than three times that of steel—and a thermal conductivity rivaling aluminum. Crucially, its coefficient of thermal expansion (CTE) can be engineered to match that of optical glasses or silicon wafers, enabling near-zero differential expansion in hybrid assemblies. A Si-SiC square used as a master reference in an EUV lithography tool won’t just hold its form—it will actively resist distortion from localized heating or vibration.

What makes these achievements possible is not just the material, but the mastery of ceramic measuring instruments fabrication. Precision machining of Si-SiC, for example, requires diamond grinding wheels, sub-micron CNC platforms, and multi-stage lapping processes conducted in temperature-controlled environments. Even minor residual stress from improper sintering can lead to post-machining warpage. That’s why only a select few global manufacturers integrate material synthesis, precision forming, and final metrology under one roof—a capability that separates true metrology-grade producers from general ceramic suppliers.

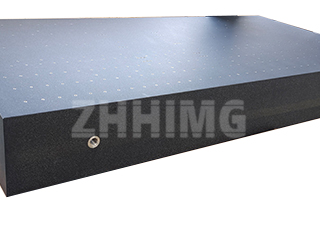

At ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (ZHHIMG), this vertical integration is central to our mission. Our ceramic measuring instruments—including ceramic air straight ruler models certified to DIN 874 Grade AA and high precision silicon-carbide (Si-Si-C) parallelepiped and square artifacts traceable to PTB and NIST standards—are produced in ISO Class 7 cleanrooms using proprietary sintering and finishing protocols. Every component undergoes full interferometric validation, CMM verification of geometric tolerances (flatness, parallelism, perpendicularity), and surface integrity testing before shipment. The result is a reference-grade artifact that doesn’t just meet specifications—it exceeds them consistently across batches.

The demand for such performance is surging. In semiconductor manufacturing, EUV and high-NA lithography systems require alignment structures stable to within tens of nanometers over meter-scale distances—impossible without Si-SiC’s thermal-mechanical synergy. In aerospace, satellite optical benches made with ceramic references ensure on-orbit stability despite extreme thermal cycling. Even in emerging fields like gravitational wave detection or atomic clock development, where picometer-level stability matters, ceramic and Si-SiC metrology artifacts are becoming indispensable.

Critically, these tools also address sustainability and total cost of ownership. While the initial investment in a high precision silicon-carbide parallelepiped may exceed that of a granite equivalent, its service life can be 5–10 times longer in high-use environments. It requires no oiling, resists all common solvents and plasmas, and never needs recalibration due to moisture absorption—unlike cast iron or even some granites. For quality managers operating under AS9100, ISO 13485, or SEMI standards, this reliability translates directly into reduced downtime, fewer audit findings, and greater customer confidence.

Moreover, the aesthetic and functional elegance of these instruments shouldn’t be overlooked. A polished Si-SiC square gleams with a metallic luster yet weighs less than steel. A ceramic air straight ruler feels solid yet lifts effortlessly—ideal for manual verification in tight spaces. These human-centered qualities matter in real-world labs where ergonomics and ease of use influence daily workflow.

So, are ceramic measuring instruments redefining ultra-high precision? The answer lies in the data—and in the growing list of global leaders who now specify them as standard. From national metrology institutes validating next-generation length standards to Tier 1 suppliers certifying EV drivetrain components, the shift is clear: when uncertainty must be minimized, engineers trust engineered ceramics.

And as industries continue their relentless march toward atomic-scale control, one truth becomes undeniable: the future of measurement won’t be carved from stone or cast in metal. It will be sintered, ground, and polished in ceramic—and silicon carbide.

ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (ZHHIMG) is a globally recognized innovator in ultra-precision ceramic and silicon-carbide metrology solutions. Specializing in ceramic measuring instruments, ceramic air straight ruler, and high precision silicon-carbide (Si-SiC) parallelepiped and square components, ZHHIMG delivers fully certified, lab-grade artifacts for semiconductor, aerospace, defense, and scientific research applications. Backed by ISO 9001, ISO 14001, and CE certifications, our products are trusted by leading technology enterprises worldwide. Explore our advanced metrology portfolio at www.zhhimg.com.

Post time: Dec-05-2025