In the high-stakes environment of modern precision engineering, the accuracy of your foundational measuring tools can make or break a product’s compliance. While a flat surface seems simple, the quality assurance industry relies on certified, meticulously crafted instruments, none more fundamental than the granite surface plate. For professionals who demand the best, understanding the distinctions in accuracy, the role of certified manufacturers like ZHHIMG granite surface plate, and the necessity of proper support is not just good practice—it is an economic imperative.

Beyond Smoothness: Deciphering Granite Plate Accuracy Grades

When sourcing a measurement foundation, engineers must look past the material and focus intensely on the tolerance achieved during the critical lapping process. This tolerance defines the grade, a certification of how closely the plate adheres to a perfect, theoretical plane. The industry uses a clear hierarchy, where tighter tolerances correspond to specific grades, often following standards like Federal Specification GGG-P-463c or DIN 876. The pinnacle of precision is represented by the grade AA granite surface plate (sometimes referred to as Grade 00). These plates offer the lowest permissible variation in flatness across the entire surface. They are the benchmark, primarily used in environmentally controlled master laboratories for primary calibration of the highest-precision instruments. If your work involves certifying reference standards or pushing the limits of dimensional measurement, Grade AA is the only acceptable choice.

Stepping down slightly, but remaining within the realm of elite precision, we find the grade 0 granite surface plate (or Grade A). This grade is the mainstay of the finest inspection rooms and quality control departments. It provides the exceptional flatness required for calibrating high-end gauging equipment, performing critical setup operations, and inspecting parts with the tightest tolerances. The difference in overall flatness tolerance between Grade AA and Grade 0 is measurable, but for most secondary calibration and high-level inspection work, Grade 0 delivers an outstanding balance of performance and practicality. While the standards are universally applied, the consistency of achieving these grades relies on the manufacturer’s expertise, equipment, and material sourcing. Companies like ZHHIMG distinguish themselves by rigorously adhering to these international standards, ensuring that when you purchase a Grade AA or Grade 0 plate, the documented uncertainty is trustworthy and traceable. For buyers accustomed to known brands, the quality must rival or surpass the performance expected from a high-quality unit, such as a grizzly granite surface plate, by maintaining strict control over the entire manufacturing and finishing process.

The Unsung Hero: The Granite Surface Plate Stand

A common error in metrology setup is focusing solely on the plate’s grade while neglecting its support. A Grade AA plate placed on an inadequate or poorly designed base is, functionally, no better than a much lower-grade plate. The structure supporting the heavy mass of the granite must prevent deflection, isolate vibration, and allow the plate to assume its manufactured flatness. This is where the specialized granite surface plate stand becomes an indispensable component.

These stands are specifically engineered to support the plate at its mathematically calculated Airy Points or Bessel Points. These points are the optimal locations to minimize overall plate deflection and distortion due to its own weight. A generic table will fail to distribute this massive weight correctly, introducing measurable errors into the reference plane. Furthermore, high-quality stands often feature built-in vibration-damping elements or leveling feet, which help to isolate the sensitive plate from floor vibrations caused by nearby machinery, foot traffic, or HVAC systems. This is particularly crucial for Grade AA and Grade 0 plates where micro-vibrations can ruin critical measurements. Finally, a good granite surface plate stand includes robust leveling jacks that allow the user to precisely level the plate. While gravity ensures a surface plate is inherently “flat” in terms of its reference plane, leveling is necessary for using bubble levels, electronic levels, and specific measuring equipment (like column gauges) that rely on a vertical or horizontal reference to the gravitational plane. Purchasing a Grade 0 plate from a reputable supplier like ZHHIMG without the correct stand is a missed opportunity. The investment in the plate’s precision is compromised if the supporting structure introduces distortion that exceeds the plate’s tolerance.

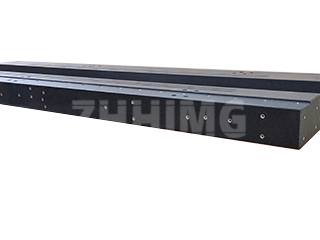

The Case for Certified Black Granite

While various types of granite are used, the most precise plates—especially those reaching grade AA granite surface plate standards—are typically made from black granite (such as black Diabase or Impala Black). This material is chosen not just for its aesthetics but for its superior physical characteristics. Black granite generally exhibits a lower porosity, meaning it absorbs less humidity, and this dimensional stability is vital in maintaining grade accuracy across varying humidity levels. It is also denser and has a higher Modulus of Elasticity than lighter granites, which helps the plate resist deflection under the weight of measuring equipment and parts. Crucially, the coefficient of thermal expansion (CTE) is exceptionally low. This means that if the temperature fluctuates in the inspection room, the granite plate changes dimension less than virtually any other material, preserving the reference plane’s integrity. When you select a high-grade product like a ZHHIMG granite surface plate, you are buying into the entire material science package, which includes the superior properties of the granite itself, coupled with expert lapping.

Maintenance and Lifespan: Preserving Your Investment

The longevity of a grade 0 granite surface plate or any high-precision instrument depends entirely on its care. Neglect can quickly degrade its accuracy, effectively turning a Grade 0 into a Grade 1 or worse, and necessitating costly re-calibration or re-lapping. Routine maintenance dictates that one should never use household cleaners or abrasive materials; specialized surface plate cleaners are formulated to remove oil, dust, and minute contaminants without damaging the surface. Dust and grit are, in fact, the primary causes of localized wear. Furthermore, proper loading protocol requires placing workpieces gently, never sliding or dragging heavy or rough components across the granite, as the micro-abrasion caused by this action wears down the surface over time. Adhering to a strict calibration schedule (typically 6 to 12 months for high-grade plates in heavy use) is non-negotiable. Calibration ensures that the plate’s flatness remains within its certified tolerance and provides an official record of its accuracy. Ultimately, investing in a high-quality foundation—whether a grade AA granite surface plate for the lab or a durable setup featuring a ZHHIMG granite surface plate on a dedicated granite surface plate stand—is a testament to a company’s commitment to quality. The difference between an accurate measurement and a failed part often comes down to the integrity of this single, silent, and essential piece of equipment.

Post time: Nov-26-2025