In today’s world of advanced manufacturing, “3D instruments” no longer refer only to coordinate measuring machines. The term now encompasses a broad ecosystem: laser trackers, structured-light scanners, photogrammetry rigs, multi-sensor metrology cells, and even AI-driven vision systems used in everything from aerospace assembly to biomedical prototyping. These tools promise unprecedented resolution, speed, and automation—but their performance is only as reliable as the surface they stand on. At ZHHIMG, we’ve seen too many high-end 3D instruments underperform not because of faulty optics or software, but because they’re mounted on bases that simply can’t meet the demands of true precision metrology.

The solution isn’t more calibration—it’s better physics. And for over two decades, that physics has pointed consistently to one material: granite. Not as a nostalgic relic, but as a scientifically optimal foundation for any system where microns matter. Whether you’re scanning a turbine blade with sub-10µm point spacing or aligning robotic arms in a digital twin workflow, the stability of your granite machine base for 3D instruments directly determines the trustworthiness of your data.

Granite’s advantages are rooted in immutable physical properties. Its coefficient of thermal expansion—typically between 7 and 9 × 10⁻⁶ per °C—is among the lowest of any engineering material commonly available. In practical terms, this means a 2-meter granite slab will expand or contract by less than 2 microns across a typical factory temperature swing of 5°C. Compare that to steel (≈12 µm) or aluminum (≈60 µm), and the difference becomes stark. For 3D instruments that rely on absolute spatial referencing—like laser trackers used in aircraft wing alignment—this thermal neutrality isn’t optional; it’s essential.

But thermal stability is only half the story. The other critical factor is vibration damping. Modern factories are noisy environments: CNC spindles spin at 20,000 RPM, robots slam into end stops, and HVAC systems pulse through the floor. These vibrations, often imperceptible to humans, can blur optical scans, jitter probe tips, or desynchronize multi-sensor arrays. Granite, with its dense crystalline structure, naturally absorbs and dissipates these high-frequency oscillations far more effectively than metal frames or composite tables. Independent lab tests have shown that granite bases reduce resonant amplification by up to 65% compared to cast iron—a difference that translates directly into cleaner point clouds and tighter repeatability.

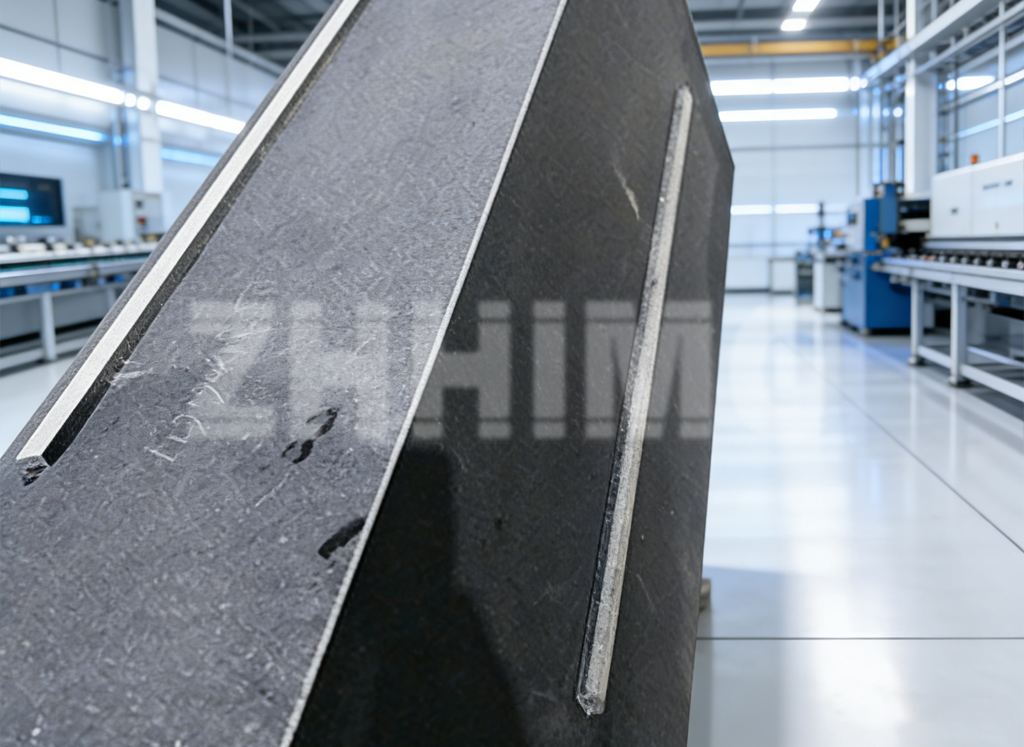

At ZHHIMG, we don’t treat granite as a commodity. Every granite machine bed for 3D instruments we produce begins with rigorously selected raw blocks—typically fine-grained black diabase or gabbro from certified European and North American quarries known for low porosity and consistent density. These blocks undergo 12 to 24 months of natural aging to relieve internal stresses before entering our climate-controlled metrology hall. There, master technicians hand-lap surfaces to flatness tolerances within 2–3 microns over spans exceeding 3 meters, then integrate threaded inserts, grounding lugs, and modular fixturing rails using techniques that preserve structural integrity.

This attention to detail extends beyond the base itself. Increasingly, clients require more than just a flat surface—they need integrated support structures that maintain metrological coherence throughout the entire instrument frame. That’s why we’ve pioneered the use of granite mechanical components for 3D instruments, including granite crossbeams, granite probe nests, granite encoder mounts, and even granite-reinforced gantry columns. By embedding granite into key load-bearing nodes, we extend the thermal and vibrational stability of the base upward into the moving architecture of the instrument. One recent client in the semiconductor equipment sector replaced carbon-fiber arms with hybrid granite-composite linkages in their custom 3D alignment rig—and saw measurement drift drop by 58% over an 8-hour shift.

Of course, not all applications demand full monolithic slabs. For portable or modular setups—such as field-deployable photogrammetry stations or mobile robot calibration cells—we offer precision-ground granite tiles and reference plates that serve as localized datums. These smaller precision granite for 3D instruments elements can be embedded into workbenches, robot pedestals, or even cleanroom floors, providing a stable anchor point wherever high-fidelity spatial referencing is needed. Each tile is individually certified for flatness, parallelism, and surface finish, ensuring traceability to ISO 10360 standards.

It’s worth addressing a common misconception: that granite is heavy, fragile, or outdated. In reality, modern handling and mounting systems make granite platforms safer and easier to install than ever. And while granite is dense, its durability is unmatched—our oldest installations, dating back to the early 2000s, remain in daily service with no degradation in performance. Unlike painted steel that chips or composites that creep under load, granite improves with age, developing a smoother surface through gentle use. It requires no coatings, no maintenance beyond routine cleaning, and zero recalibration due to material fatigue.

Moreover, sustainability is inherent in this approach. Granite is 100% natural, fully recyclable, and sourced with minimal environmental impact when responsibly quarried. In an era where manufacturers are scrutinizing the lifecycle footprint of every asset, a granite foundation represents a long-term investment—not just in accuracy, but in responsible engineering.

We take pride in transparency. Every ZHHIMG platform ships with a full metrology report—including flatness maps, thermal drift curves, and vibration response profiles—so engineers can validate suitability for their specific application. We don’t rely on “typical” specs; we publish actual test data because we know that in precision metrology, assumptions cost money.

This rigor has earned us partnerships with leaders across industries where failure is not an option: aerospace OEMs validating fuselage sections, medical device firms inspecting implant geometries, and EV battery producers aligning gigafactory tooling. One German automotive supplier recently consolidated three legacy inspection stations into a single ZHHIMG-based multi-sensor cell featuring both tactile probes and blue-light 3D scanners—all referenced to the same granite datum. The result? Measurement correlation improved from ±12 µm to ±3.5 µm, and cycle time dropped by 45%.

So as you evaluate your next metrology deployment, ask yourself: is your current setup built on a foundation designed for truth—or compromise? If your 3D instruments require frequent recalibration, if your scan-to-CAD deviations fluctuate unpredictably, or if your uncertainty budget keeps expanding, the issue may lie not in your sensors, but in what supports them.

At ZHHIMG, we believe that precision should be inherent, not compensated for. Visit www.zhhimg.com to explore how our precision granite for 3D instruments, combined with purpose-built granite mechanical components for 3D instruments, is helping engineers around the world turn measurement data into actionable confidence. Because when every micron counts, there’s no substitute for solid ground.

Post time: Jan-05-2026