As the “benchmark cornerstone” of precision measurement and manufacturing, calibration granite platforms, with their exceptional flatness and parallelism stability, have penetrated key fields such as precision manufacturing, aerospace, automotive, and metrology research. Their core value lies in providing a “zero-error” reference surface for a variety of high-precision inspection and assembly scenarios, adapting to the needs of the entire supply chain, from traditional machining to intelligent metrology systems.

Core Application Scenarios and Industry Compatibility

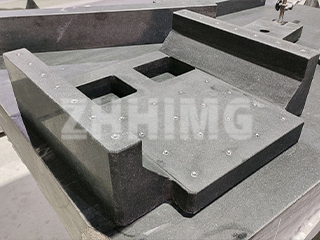

In precision manufacturing, granite platforms are the “gatekeepers” of quality control: geometric accuracy calibration of CNC machine tools, micron-level inspection of mold flatness, and dimensional verification of 3D-printed parts all rely on the stable reference surface they provide. For example, in mold manufacturing, the platform, combined with a height gauge, can accurately measure cavity depth, ensuring the consistency of molded parts with the design drawings.

The aerospace industry’s extreme pursuit of precision has made granite platforms a high-end application. Surface contour inspection of turbine blades, bore tolerance measurement of engine blocks, and even the assembly and positioning of satellite components all require platforms as aerospace calibration plates to provide submicron-level surface references. Data from an aviation manufacturing company shows that using a 00-grade granite platform reduced measurement errors in engine components by 15%, directly improving overall machine reliability.

In the automotive industry’s mass production, platforms serve as “quality guardians”: measuring gear meshing clearances in transmissions and verifying the thickness uniformity of brake pads. In conjunction with equipment such as optical comparators, they enable efficient quality inspection of batches of parts. A leading automotive company revealed that adopting a granite platform with T-slots on its production line has increased component clamping efficiency by 30% and improved test data stability by 22%.

In metrology laboratories, granite platforms are standard-setters. As the CMM granite base for coordinate measuring machines (CMMs), they provide a reference plane for length measurement, ensuring the calibration accuracy of gauge blocks, micrometers, and other measuring instruments. Leading global metrology laboratories, such as NIST (National Institute of Standards and Technology), base their length reference systems on high-precision granite platforms. Global Market Distribution and Regional Preferences

Market demand in different regions exhibits significant differences, reflecting the deep integration of industry standards and application scenarios:

Global Market Landscape

North America (32%): Driven primarily by the aerospace and semiconductor industries, it emphasizes high precision and certification compliance, such as NIST traceability and ISO 17025 laboratory accreditation. Typical applications include profile measurement of aircraft engine blades.

Europe (38%): Dominated by the precision instrument and automotive manufacturing sectors, it prefers DIN standards and environmentally friendly materials, such as low-emissivity granite that complies with DIN 876. German automotive giant Bosch Group specifies this platform for autonomous driving sensor calibration.

Asia-Pacific (CAGR 7.5%): China and India are the primary growth engines, driven by booming demand in electronics manufacturing (such as chip packaging and testing) and new energy vehicles. Local manufacturers are leveraging cost advantages to capture the low- and mid-range markets while accelerating ISO 17025 certification to break through barriers in the high-end market.

From functional adaptation to regional customization, the calibration granite platform is driving the dual-wheel drive of “scenario-based design + standardized certification,” becoming a core hub connecting precision manufacturing and quality control. Whether serving as a CMM granite base to support high-end measurement equipment or as an aerospace calibration plate to ensure aviation safety, its “benchmark value” in the wave of Industry 4.0 will continue to stand out.

Post time: Sep-11-2025