In precision measurement, one common challenge arises when the workpiece to be inspected is larger than a single granite surface plate. In such cases, many engineers wonder whether a jointed or assembled granite surface plate can be used and if the joint seams will affect measurement accuracy.

Why Choose a Jointed Granite Surface Plate

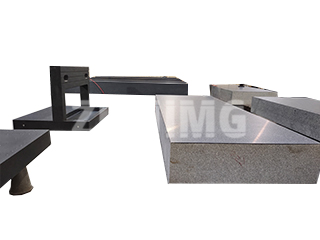

When inspection dimensions exceed the limits of a single stone block, a jointed granite platform becomes an ideal solution. It allows large measuring areas to be formed by joining multiple precision granite slabs together. This method not only saves on transportation and installation costs but also makes it possible to construct custom ultra-large measurement platforms directly on site.

Precision Assurance After Assembly

A properly jointed granite platform, when manufactured and installed by professionals, can achieve the same accuracy level as a single-piece surface plate. The key lies in:

-

High-precision matching and lapping of the contact surfaces.

-

Professional adhesive bonding and mechanical positioning to ensure zero displacement.

-

Final on-site calibration using precision instruments such as laser interferometers or electronic levels.

At ZHHIMG®, each jointed platform is assembled under temperature-controlled conditions and verified according to DIN, ASME, and GB standards. After assembly, the overall flatness and continuity across the seams are adjusted to micron-level accuracy, ensuring the surface behaves as one unified reference plane.

Does the Joint Affect Accuracy?

In standard applications, no—a correctly assembled joint will not affect measurement precision. However, improper installation, unstable foundation, or environmental vibration can cause local deviation. Therefore, professional installation and periodic recalibration are crucial to maintaining long-term accuracy.

ZHHIMG® Expertise in Large Granite Platforms

With advanced manufacturing capability and over 200,000 m² of production space, ZHHIMG® specializes in custom large-scale granite platforms, including modular and jointed types up to 20 meters in length. Our strict metrology verification and experience with international standards ensure stable, traceable precision performance.

Conclusion

A jointed granite surface plate is a reliable, efficient solution for large-scale precision inspection tasks. With expert design, assembly, and calibration, its performance equals that of a monolithic plate—proving that precision has no limits, only craftsmanship does.

Post time: Oct-15-2025