In the highly automated world of ultra-precision engineering, where complex laser tracking systems and sophisticated algorithms manage motion control, it might seem counterintuitive that the ultimate geometric accuracy still relies on tools dating back to the earliest days of metrology. Yet, as the industry pushes deeper into the sub-micron and nanometer domains, the foundational role of precision granite tools—specifically the granite straight ruler with Grade 00 precision, the granite square, and the granite tri square—is not merely sustained, but amplified. These static, passive instruments are the immutable reference points that validate the performance of the most advanced dynamic systems.

The necessity of these granite reference tools stems from a fundamental physical principle: thermal and mechanical stability. Any machine designed for high precision must ensure that its measurement planes and linear travel are true, straight, and perpendicular. When modern manufacturing demands dimensional stability that is unaffected by temperature fluctuations or external vibrations, materials like steel or cast iron—with their relatively high coefficient of thermal expansion (CTE) and low damping capacity—fail the test.

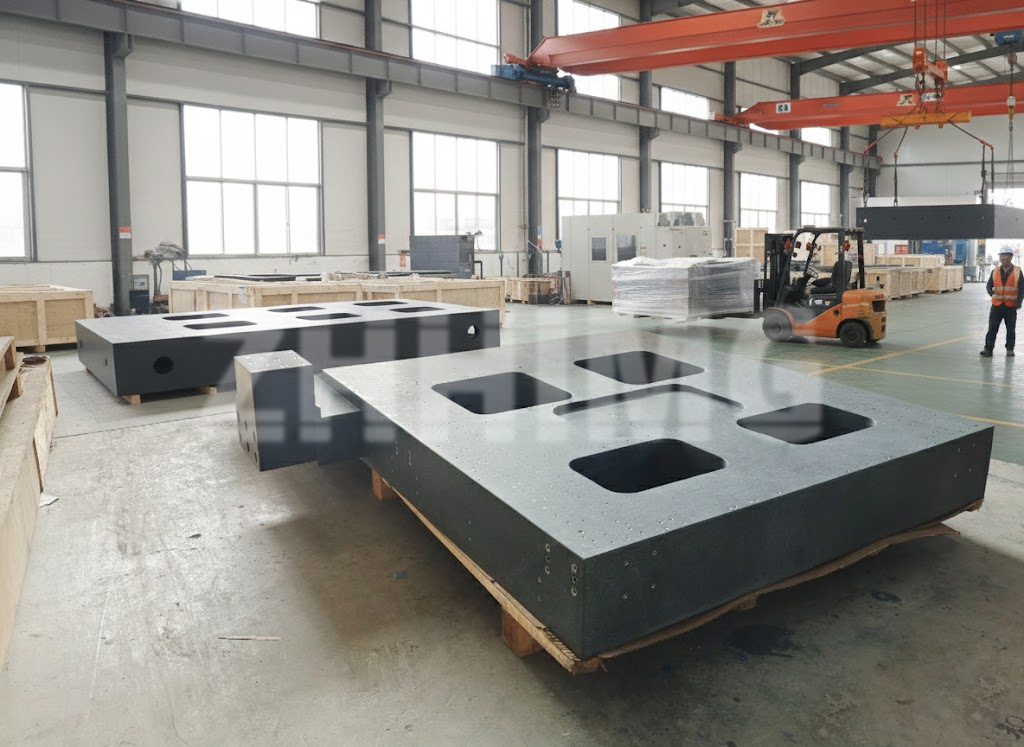

Granite, on the other hand, provides the ideal environment for stability. Its low CTE means that temperature changes cause minimal dimensional drift, making it the perfect material for defining a reference plane that remains predictable. Furthermore, its inherent high damping capability absorbs vibrations quickly, preventing the chatter and resonance that metal tools would propagate, which is critical in metrology labs and assembly environments where ambient noise is a constant challenge.

The Foundation of Linearity: Granite Straight Ruler with Grade 00 Precision

The measurement of straightness is the cornerstone of dimensional metrology. Every linear guide, air bearing, and CMM axis relies on a verifiable straight path of motion. For truly demanding applications, the granite straight ruler with Grade 00 precision becomes the absolute authority.

The designation of Grade 00 (or equivalent Master Grade) signifies the highest level of accuracy achievable outside of national standards laboratories. This level of precision requires that the straightness deviation along the entire working edge of the ruler must be measured in fractions of a micron. Achieving this level of geometric fidelity requires not only the ideal material but also a meticulously controlled manufacturing process.

The manufacturing process must adhere to stringent international specifications, such as DIN, JIS, ASME, or GB standards. These global standards dictate the testing procedures, environmental conditions, and acceptable tolerances. For manufacturers who serve global clients—from Japanese semiconductor firms to German machine tool builders—the ability to certify a granite straight ruler against multiple standards simultaneously is an indication of technical mastery and quality system robustness. This ruler’s function is simple: to provide a passive, unchangeable line against which the straightness error of a dynamic machine axis can be mapped and compensated.

Defining Perpendicularity: The Granite Square and Granite Tri Square

While straightness dictates the quality of linear motion, perpendicularity (or squareness) dictates the functional geometry of the machine. The intersection of motion axes (such as the X and Y axes, or the Z axis relative to the base plane) must be precisely 90°. Any deviation here, known as squareness error, translates directly into positional error, compounding the difficulty of achieving precise feature placement.

The granite square and the granite tri square are the primary tools used to verify this fundamental angle.

-

The granite square is typically used to verify the squareness of machine axes relative to a reference surface plate or to verify the perpendicularity of components during assembly. Its robust L-shaped geometry ensures that the two working faces are maintained at a certified 90° angle.

-

The granite tri square (or master square) offers a unique three-face geometric configuration, allowing a more comprehensive check of the cubic geometry within a machine frame. This configuration is particularly useful for establishing the cubic boundaries of CMMs or large machine frames, ensuring that all planes are square to each other and to the base.

Like the straight ruler, these squares must achieve Grade 00 certification, requiring the angles to be true to within arc-seconds. This is a task dependent on the supreme stability of the granite material and the irreplaceable skill of master craftsmen who utilize decades of experience in the hand-lapping process to achieve the final, flawless surface geometry.

The Craftsmanship Ecosystem: More Than Just Stone

The authority of these granite metrology tools is not just in the material, but in the entire ecosystem supporting their certification and manufacture. Companies that lead in this field understand that precision is a culture, not just a product specification.

It begins with the master artisans. In specialized, highly controlled workshops, precision grinding masters often possess thirty or more years of experience. These individuals are adept at using specialized lapping plates and abrasive compounds to manually correct microscopic imperfections, often working to tolerances that their hands can detect better than most electronic sensors. Their accumulated knowledge allows them to achieve surface finishes that push the boundaries of flatness and straightness, sometimes reaching down to the nanometer scale for the absolute smoothest finish required by air bearing applications. This human mastery is the core differentiator in achieving the stringent Grade 00 requirements.

This craftsmanship is rigorously audited and verified. The manufacturing environment must itself be ultra-stable, featuring climate-controlled clean rooms, anti-vibration concrete foundations, and specialized measuring equipment like laser interferometers and electronic levels that are themselves regularly calibrated and traceable to national standards laboratories. This commitment ensures that the component’s certified geometry remains true from the moment it leaves the factory floor.

The reliance on these ancient yet perfected tools underscores a profound truth in ultra-precision engineering: the pursuit of dynamic speed and computational complexity must always be tethered to a static, verifiable geometric reality. The granite straight ruler with Grade 00 precision, the granite square, and the granite tri square are not relics of the past; they are the necessary, unyielding standards that guarantee the geometric integrity of the future. By maintaining the strictest adherence to DIN, JIS, ASME, and GB standards, specialist manufacturers ensure that a basic piece of stone remains the most sophisticated tool available for defining dimensional truth.

Post time: Dec-08-2025