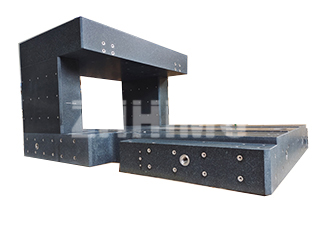

When it comes to custom granite surface plates, many users ask whether it is possible to add engraved surface markings—such as coordinate lines, grids, or reference markings. The answer is yes. At ZHHIMG®, we not only manufacture precision granite surface plates, but also provide custom engraving solutions to enhance usability in metrology and assembly applications.

Why Add Surface Markings?

Surface markings such as coordinate lines or grid patterns make granite surface plates more versatile:

-

Positioning & Alignment – Coordinate lines help engineers align workpieces and instruments quickly.

-

Measurement Reference – Grids or cross-lines act as visual guides for dimensional inspection.

-

Assembly Support – Markings improve efficiency in equipment assembly or calibration.

This added functionality turns a granite surface plate from a flat reference plane into a multi-purpose precision tool.

Engraving Accuracy

A common concern is whether engraving will compromise the flatness or accuracy of the granite surface plate. At ZHHIMG®, we follow strict guidelines:

-

Engraving is performed only after the plate has been ground and lapped to the required flatness.

-

Markings are shallow and carefully processed so as not to affect the overall surface precision.

-

Engraving accuracy can typically reach ±0.1mm, depending on the pattern complexity and customer requirements.

This ensures that flatness tolerance and calibration results remain unchanged, while the user benefits from added precision markings.

Customization Options

Customers can request a wide variety of markings, including:

-

Coordinate grids (X-Y axis lines)

-

Center reference points

-

Crosshair markings for optical alignment

-

Custom scales or rulers engraved directly on the plate

Markings can also be filled with contrasting color (such as white or yellow) for better visibility without affecting accuracy.

Applications of Engraved Granite Surface Plates

Granite surface plates with engraved markings are widely used in:

-

Metrology laboratories for calibration and inspection

-

Optical equipment assembly for accurate positioning

-

Precision machining workshops for part alignment

-

Semiconductor and electronics industries where high-accuracy setups are required

By combining high flatness tolerance with visual reference grids, users achieve greater efficiency and precision in day-to-day operations.

Why Choose ZHHIMG®?

ZHHIMG® is recognized globally for custom precision granite solutions. With decades of expertise, advanced CNC engraving systems, and skilled technicians, we ensure:

-

Nanometer-level surface flatness before engraving

-

Engraving precision up to ±0.1mm

-

Compliance with international standards (DIN, JIS, ASME, GB)

-

Calibration certificates traceable to national metrology institutes

This makes ZHHIMG® the trusted partner for world-class industries, from semiconductor manufacturers to research institutes.

Conclusion

Yes, it is possible to request engraved coordinate lines or grid markings on custom granite surface plates. With advanced engraving technology and strict quality control, ZHHIMG® ensures that precision markings enhance usability without compromising accuracy. For customers who require both flatness and functionality, a granite surface plate with engraved markings is the ideal solution.

Post time: Sep-26-2025