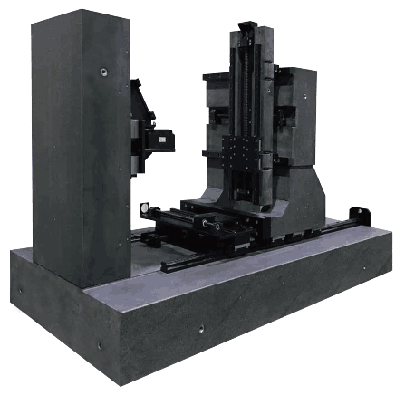

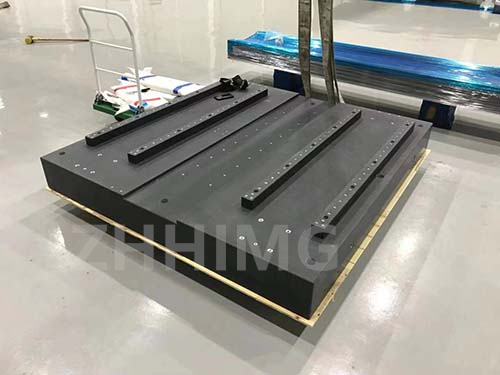

In the semiconductor and display manufacturing industries, array inspection equipment plays a vital role in ensuring product quality. The efficiency of these machines can be significantly enhanced by the choice of machine base material, and granite has emerged as a game - changer in this regard.

Unparalleled Stability for Consistent Performance

Array inspection requires pinpoint accuracy, as even the slightest deviation can lead to false positives or missed defects. Granite machine bases, with their high density of around 3100 kg/m³, offer exceptional stability. During the inspection process, the equipment may be subject to vibrations from nearby machinery or environmental factors. The stable structure of granite effectively resists these external disturbances, keeping the inspection sensors and optical components precisely aligned. This stability ensures that the equipment can continuously and accurately scan arrays, reducing the need for re - inspections and improving overall throughput. For example, in a panel display factory, the adoption of granite machine bases in array inspection equipment led to a 20% increase in daily inspection capacity.

Superior Vibration Damping for Faster Operations

Vibrations can severely hamper the speed of array inspection. When the inspection equipment vibrates, the scanning speed often has to be reduced to maintain accuracy, which slows down the entire process. Granite’s natural vibration - damping properties are a major advantage here. Its unique internal structure, composed of interlocking mineral grains, absorbs and dissipates vibration energy effectively. With a granite machine base, the array inspection equipment can operate at higher scanning speeds without sacrificing precision. In a semiconductor manufacturing facility, after replacing the original metal base with a granite one, the inspection speed of integrated circuit arrays increased by 30%, enabling faster production cycles.

Thermal Resistance for Extended Operational Time

Temperature fluctuations are common in manufacturing environments, and they can affect the performance of array inspection equipment. Some materials may expand or contract with temperature changes, causing misalignment of components and inaccurate inspections. Granite has a low thermal expansion coefficient, which means it maintains its shape and dimensions even under varying temperatures. This thermal stability allows the array inspection equipment to operate continuously without the need for frequent temperature - induced adjustments. As a result, the equipment can run for longer periods, maximizing its utilization and improving efficiency. In a high - volume production line, the use of granite machine bases reduced equipment downtime due to thermal issues by 40%.

Long - lasting Durability for Cost - effective Operations

Array inspection equipment is used continuously in industrial settings, and the machine base needs to withstand the rigors of daily operation. Granite is highly durable, with excellent wear - resistance and chemical inertness. It can resist the mechanical stress, friction, and potential chemical exposure in the manufacturing environment. This long - lasting durability reduces the frequency of base replacements and maintenance, lowering overall operational costs. Moreover, a reliable granite machine base ensures the long - term stable performance of the array inspection equipment, further contributing to enhanced efficiency.

In conclusion, granite machine bases can indeed significantly improve the efficiency of array inspection equipment. Their stability, vibration - damping capabilities, thermal resistance, and durability work together to enable faster, more accurate, and more reliable inspections. For manufacturers looking to optimize their production processes and increase the productivity of their array inspection operations, investing in high - quality granite machine bases, such as those provided by ZHHIMG®, is a wise decision that can yield substantial benefits.

Post time: Jun-10-2025