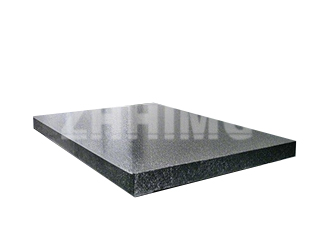

For decades, the global precision engineering sector has understood the undeniable advantages of using granite over traditional materials like cast iron or steel for critical metrology and machine tool foundations. Granite machine components, such as the high-density bases and guides engineered by ZHONGHUI Group (ZHHIMG®), are prized for their superior, stable accuracy, virtual immunity to long-term creep deformation, and innate resistance to rust and magnetic interference. These qualities make granite the ideal reference plane for sophisticated instruments like Coordinate Measuring Machines (CMMs) and advanced CNC machining centers. Despite these inherent strengths, are granite components truly immune to degradation, and what sophisticated measures are required to prevent staining and efflorescence (alkali bloom)?

While granite, by nature, cannot rust, it is susceptible to environmental and chemical challenges. Staining and efflorescence—the process where soluble salts migrate and crystallize on the surface—can compromise the component’s aesthetic and cleanliness, which is a factor in maintaining a high-precision environment. To combat these issues, a proactive chemical defense strategy is essential, one that is carefully tailored to the granite’s specific characteristics and its working environment.

Tailored Chemical Protection: A Proactive Strategy

Preventing degradation involves the judicious selection of penetrating sealants. For components deployed in areas prone to spillage and high contamination, such as specialized industrial processing zones, an impregnating sealer enriched with functional fluorochemicals is highly recommended. These compounds provide a robust barrier that significantly boosts the stone’s oil and stain resistance, safeguarding the component without altering its dimensional integrity. Conversely, granite components used in outdoor or harsh industrial settings require protection with sealants containing functional silicones. These specialized formulas must deliver multiple benefits, including high water repellency, UV resistance, and anti-acid properties, ensuring the structural stability is maintained against environmental degradation.

The choice between sealant types often hinges on the granite’s internal structure. For granite that may have a slightly looser composition and higher permeability, an oil-based impregnator is preferred, as its deeper penetration ensures maximum internal nourishment and protection. For our ultra-dense ZHHIMG® Black Granite, which meets strict standards for low water absorption, a high-quality water-based sealant is typically sufficient for effective surface protection. Furthermore, when selecting cleaning agents, it is critical to use powerful, non-silicone-based formulas. This prevents the deposition of residues that could contaminate the measurement environment or interfere with subsequent tooling operations.

The Technical Integrity Behind Granite Performance

The sustained reliability of ZHHIMG® components stems from strict adherence to technical standards. These standards mandate the use of fine-grained, dense materials like gabbro, diabase, or specific granite types that maintain a biotite content below 5% and a water absorption rate under 0.25%. The working surface must achieve a hardness exceeding HRA 70 and possess a required surface roughness (Ra). Crucially, the final dimensional accuracy is verified against stringent tolerances for flatness and squareness.

For the most exacting precision grades, such as Grade 000 and 00, the design avoids incorporating features like handling holes or side handles to prevent any subtle, introduced stress that could compromise the final accuracy. While minor cosmetic flaws on non-working surfaces may be repairable, the working plane must remain pristine—completely free of pores, cracks, or contaminants.

By combining the inherent stability of high-quality granite with these rigorous technical requirements and a customized approach to chemical preservation, engineers ensure that ZHHIMG® machine components remain reliable, high-precision reference tools throughout their exceptionally long service life.

Post time: Nov-19-2025