In the precision manufacturing of glass components for electronics, optics, and architecture, achieving strict drilling tolerances (often within ±5μm or tighter) is critical. High-precision granite bases have emerged as a game-changing solution, leveraging their unique physical properties to enhance drilling accuracy and consistency. This article explores how granite bases enable stricter tolerance control in glass drilling operations.

The Critical Role of Tolerance in Glass Drilling

- Optical glass components require hole tolerances within ±2μm to avoid light refraction errors

- Display panels need uniform hole spacing to ensure touchscreen functionality

- Medical devices demand burr-free holes with strict dimensional control for fluidic applications

How Granite Bases Enhance Drilling Precision

1. Superior Vibration Damping for Micro-Accuracy

Granite’s dense structure (3,000–3,100 kg/m³) and interlocking mineral grains act as a natural shock absorber:

- Vibration attenuation rate >90% at typical drilling frequencies (20–50Hz)

- Reduces tool chatter, preventing micro-cracks around drill holes

- Case study: A display manufacturer using granite bases reduced hole diameter variation from ±8μm to ±3μm

2. Thermal Stability for Consistent Tolerances

With a low coefficient of thermal expansion (4–8×10⁻⁶/°C), granite maintains dimensional stability:

- Minimizes thermal deformation during prolonged drilling operations

- Ensures hole position accuracy even in environments with ±5°C temperature fluctuations

- Compared to steel bases, granite reduces thermal-induced errors by 60%

3. High Hardness for Long-Term Precision

Granite’s Mohs hardness of 6–7 resists wear better than metal or composite bases:

- Maintains surface flatness (±0.5μm/m) over extended use

- Reduces the need for frequent machine recalibration

- A semiconductor glass substrate producer reported 70% less tool wear with granite bases

4. Rigid Foundation for Tool Path Accuracy

Precision-ground granite surfaces (Ra≤0.1μm) provide an ideal mounting platform:

- Enables precise alignment of drilling axes

- Reduces positional errors caused by base deflection

- Improves hole perpendicularity to within 0.01°

Case Study: Granite Bases in Optical Glass Drilling

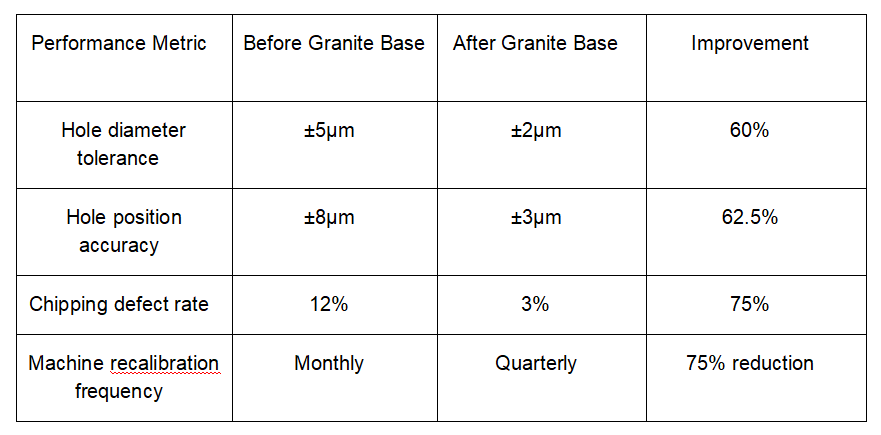

A leading optical component manufacturer upgraded to ZHHIMG® high-precision granite bases for their CNC glass drilling machines:

The results demonstrate how granite bases enable manufacturers to meet the strict tolerances required for high-end optical components.

SEO-Optimized Key Takeaways

- High-precision granite bases are essential for achieving ±5μm or tighter tolerances in glass drilling

- Their vibration-damping, thermal stability, and wear resistance properties address key precision challenges

- Case studies show significant improvements in hole accuracy and reduced defect rates

- Ideal for industries requiring strict glass component tolerances: optics, electronics, medical devices

By integrating high-precision granite bases into glass drilling setups, manufacturers can elevate their precision capabilities, meet stricter quality standards, and gain a competitive edge in high-value markets.

Post time: Jun-12-2025