Granite precision surface plates have long been regarded as one of the most reliable foundations in dimensional metrology. They provide a stable reference surface for inspection, calibration, and high-accuracy measurements across industries such as semiconductor manufacturing, aerospace, CNC machining, and optical metrology. While their importance is unquestioned, there is one concern that often appears in technical forums and customer inquiries: how does humidity affect granite surface plates? Can moisture cause granite to deform or lose its accuracy?

The answer, according to research and decades of industrial experience, is reassuring. Granite, particularly high-density black granite, is an extremely stable natural material with negligible hygroscopic properties. Unlike porous stones such as marble or limestone, granite is formed through the slow crystallization of magma deep within the Earth’s crust. This process results in a dense structure with very low porosity. In practical terms, this means that granite does not absorb water from the air, nor does it swell or deform in humid environments.

In fact, this resistance to moisture is one of the key reasons why granite has replaced cast iron in many metrology applications. Where cast iron may rust or corrode when exposed to high humidity, granite remains chemically stable. Even in workshops with relative humidity levels above 90%, precision granite plates maintain their dimensional stability and flatness. Tests carried out in controlled environments confirm that the flatness of a granite surface plate remains within micrometer tolerances regardless of changes in atmospheric moisture.

That said, while granite itself is not affected by humidity, the overall measurement environment still matters. Condensation can occur in poorly regulated workshops when temperatures drop suddenly, and although granite does not rust, condensed water may leave behind dust or contaminants that interfere with measurement. Instruments placed on granite, such as dial gauges, electronic levels, or coordinate measuring machines, are often more sensitive to environmental conditions than the granite base itself. For this reason, laboratories and workshops are encouraged to maintain stable temperature and humidity controls not only for granite but also for the instruments that depend on it.

The superior moisture resistance of granite is particularly valuable in industries where environmental conditions are difficult to control. Semiconductor fabs, aerospace facilities, and research laboratories often operate with strict environmental standards, but granite’s stability ensures an additional layer of security. In regions with naturally humid climates, from Southeast Asia to coastal Europe, granite surface plates have consistently proven to be more reliable than alternatives.

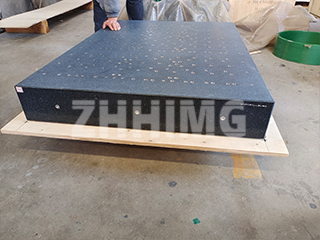

At ZHHIMG®, the black granite selected for precision products offers an even greater level of performance. With a density of approximately 3100 kg per cubic meter and a water absorption rate of less than 0.1%, it provides unmatched stability. This ensures that flatness and accuracy are maintained over long periods of use. Customers in semiconductor manufacturing, optics, CNC machining, and national metrology institutes rely on these properties when absolute precision is required.

Another factor to consider is maintenance. Even though granite is not affected by moisture, best practices help extend its service life. Regular cleaning with a lint-free cloth prevents dust accumulation. Protective covers can keep surfaces free from airborne particles when the plate is not in use. Periodic calibration with certified instruments verifies long-term accuracy, and this is especially important in high-precision environments where tolerances can reach the sub-micron level. In all of these cases, granite’s inherent resistance to humidity makes the task easier and more predictable than with metals or other materials.

The question of humidity and granite precision plates often comes from a natural concern: in precision engineering, even the smallest environmental influence can have measurable effects. Temperature, for example, is a critical factor in dimensional stability. Granite’s low coefficient of thermal expansion already makes it one of the best materials for controlling this variable. When it comes to moisture, however, engineers can rest assured that granite is one of the most reliable choices available.

For companies and laboratories that invest heavily in metrology infrastructure, material choice is not just about performance today but also about stability for decades to come. Granite has proven itself to be a long-term partner in this mission. Its resistance to humidity means that it can be installed and used in a wide variety of environments, from cleanrooms to heavy-duty industrial facilities, without concern that moisture will degrade its accuracy.

In conclusion, humidity does not pose a threat to the stability or precision of granite surface plates. Thanks to its dense, non-hygroscopic nature, granite remains unaffected by moisture and continues to provide the stable reference required in modern metrology. While environmental control remains important for instruments and overall accuracy, the granite itself can be trusted to resist humidity-related changes. This is why, across industries and around the world, granite remains the material of choice for precision measurement foundations.

At ZHONGHUI Group (ZHHIMG®), this knowledge is not just theoretical but proven daily in cooperation with Fortune 500 companies, leading universities, and national metrology institutes. For engineers seeking long-term reliability, granite surface plates represent not only tradition but also the future of ultra-precision measurement.

Post time: Sep-25-2025