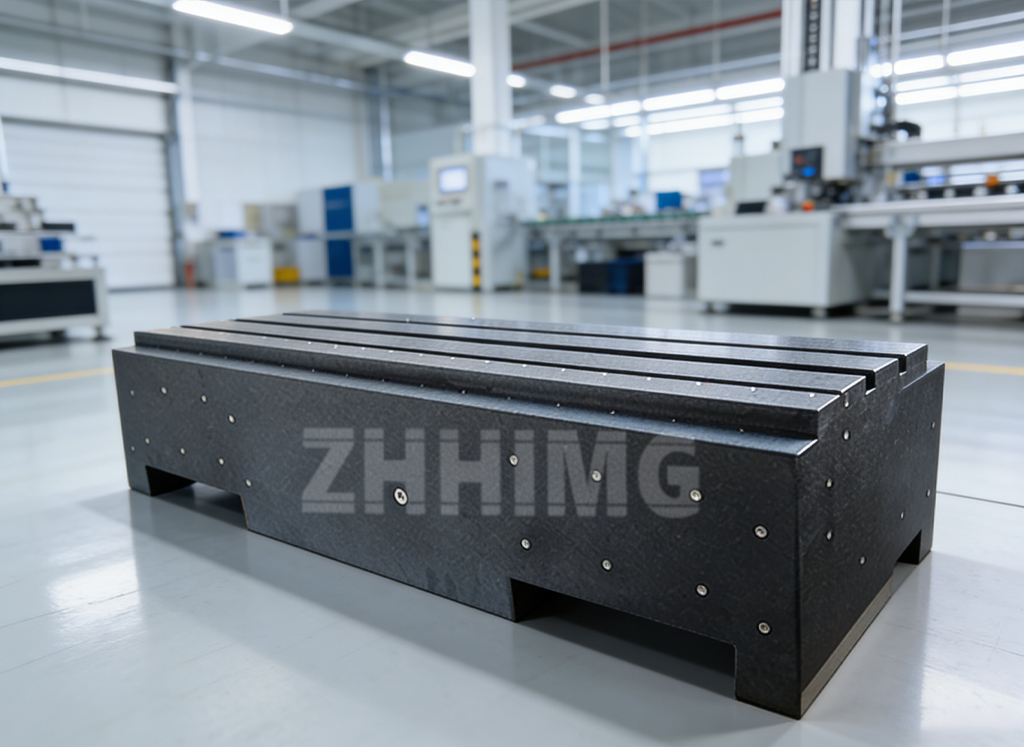

Precision granite platforms are no longer used solely as passive reference surfaces. In modern ultra-precision manufacturing, metrology, and equipment assembly, they often serve as functional structural components. This evolution naturally leads to a common and very practical question during procurement and design discussions: can mounting holes be customized on a precision granite platform, and if so, what principles should govern their layout to avoid compromising accuracy?

The short answer is yes, mounting holes can be customized, and in many advanced applications, they must be. Granite precision platforms are frequently required to interface with air bearings, linear motors, guideways, optical systems, fixtures, or complete machine assemblies. Standard hole patterns rarely meet these complex integration requirements. Custom hole layouts allow the granite platform to become an integral part of the system rather than an isolated reference surface.

However, customization does not mean unlimited freedom. Granite behaves very differently from metal, and improper hole design can introduce internal stress, reduce structural integrity, or negatively affect long-term accuracy. This is why experienced manufacturers treat hole layout as an engineering task rather than a simple machining request.

One of the most fundamental considerations is load distribution. Every mounting hole introduces a localized stress concentration in the granite. If holes are placed too close together, too close to edges, or directly beneath high-load zones, the stress field can distort the granite’s internal structure. Even if deformation is not immediately visible, it can manifest over time as subtle flatness drift. A well-designed hole layout ensures that loads from mounted equipment are transferred evenly across the granite body rather than concentrated at a few points.

The relationship between mounting holes and support points is equally critical. Precision granite platforms are typically supported at specific locations to minimize bending and gravitational deflection. If mounting holes are positioned without regard to these support points, tightening forces or operational loads may counteract the intended support geometry. In high-precision applications, this interaction can result in measurable changes in surface flatness. For this reason, hole layout design must always consider how the platform will be supported during both measurement and operation.

Depth, diameter, and threading method also matter more than many users expect. Granite does not tolerate aggressive threading or excessive depth in the same way metals do. Inserts, bushings, or bonded metal sleeves are often used to provide durable threads while protecting the surrounding stone. The choice of insert type and installation method influences not only mechanical strength but also long-term stability. Poorly installed inserts can introduce micro-cracks or residual stresses that degrade accuracy over time.

Another important principle is symmetry. Asymmetric hole patterns can lead to uneven stress distribution, especially when the platform is subjected to thermal changes or dynamic loads. While asymmetry is sometimes unavoidable due to equipment design, experienced engineers aim to balance hole placement wherever possible. Symmetry helps maintain predictable deformation behavior, which is essential for preserving flatness and geometric accuracy under real-world conditions.

Thermal behavior must also be considered when designing mounting holes. Granite has a low coefficient of thermal expansion, but metal inserts and mounted components may expand at different rates. Hole layouts that constrain components too rigidly can create thermal stress at the granite-metal interface. Allowing for controlled movement or selecting appropriate insert materials helps prevent long-term stress accumulation, particularly in environments with temperature variation.

From a manufacturing perspective, the sequence of operations is just as important as the layout itself. In high-quality production, drilling and inserting mounting holes are carefully coordinated with grinding and lapping processes. Performing heavy machining after final surface finishing risks introducing stress or surface distortion. This is why customized hole layouts should be defined early in the design phase, allowing the manufacturer to integrate them into a controlled production process rather than treating them as an afterthought.

Inspection and verification play a decisive role once customization is complete. A precision granite platform with mounting holes should be measured in its final configuration, with inserts installed and surfaces fully finished. Flatness and geometry inspection reports should reflect the actual delivered condition rather than an intermediate state. This provides confidence that customization has not compromised the platform’s role as a precision reference.

For users, understanding these principles helps set realistic expectations. Custom mounting holes are not a risk when they are engineered correctly. On the contrary, they often enhance system accuracy by ensuring proper alignment, repeatable installation, and stable load transfer. Problems arise only when hole layouts are driven purely by convenience or cost, without regard for granite’s material behavior and precision requirements.

In practical applications such as semiconductor equipment bases, precision motion systems, optical inspection platforms, and air-bearing stages, customized granite platforms with well-designed hole layouts have become standard. They demonstrate that precision granite is not a fragile material to be avoided in structural integration, but a highly capable foundation when treated with engineering discipline.

Ultimately, the question is not whether mounting holes can be customized on a precision granite platform, but whether they are designed with sufficient understanding of accuracy, stability, and long-term performance. When layout principles are respected and customization is executed with precision in mind, mounting holes become a functional advantage rather than a compromise. In ultra-precision engineering, thoughtful design is what allows granite to perform not just as a surface, but as a reliable structural reference for years to come.

Post time: Dec-15-2025