The relentless drive for miniaturization and performance in modern technology—from advanced display panels to cutting-edge scientific instrumentation—has pushed the limits of traditional engineering materials. In the pursuit of sub-micron and even nanometer-level precision, engineers are consistently turning to a material perfected over geological millennia: natural granite. This seemingly humble stone has become the non-negotiable bedrock for equipment that shapes our digital future.

The demand for uncompromising stability and accuracy in sectors like semiconductor fabrication and advanced metrology underscores why precision granite components are increasingly vital. Unlike metals, which are highly susceptible to thermal expansion and vibration, black granite offers a unique cocktail of physical properties that create the ideal environment for ultra-precise operations.

The Bedrock of Flat Panel Display Technology

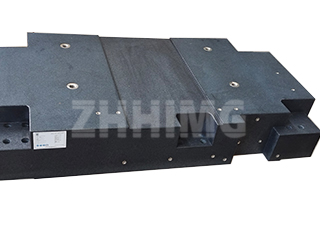

The fabrication of modern display panels—specifically those based on Amorphous Silicon (a-Si) and Low-Temperature Polycrystalline Silicon (LTPS) technologies—requires machinery that can maintain exceptional flatness and positional accuracy over large areas. This is where granite mechanical components for a-Si Array and precision granite for LTPS Array equipment become critical.

When producing large-area glass substrates for displays, even the slightest deviation in a machine’s structure can translate into costly defects and yield loss. Granite’s extremely low coefficient of thermal expansion (roughly half that of steel) ensures that the machine structure remains dimensionally stable even during minor temperature fluctuations within a cleanroom environment. Furthermore, its superb internal damping capacity—significantly higher than cast iron or steel—is essential for neutralizing microscopic vibrations. These vibrations, which might be imperceptible to the human touch, can be catastrophic to the lithography, etching, or deposition processes used to form the tiny transistors and circuits on the array. By dissipating these energies quickly, granite bases, beams, and gantry components ensure that the sensitive stages move with the fluid, repeatable precision required for high-volume, high-yield manufacturing of high-resolution displays.

The inherent stiffness of granite also means that machine components can support heavy payloads—like large gantry systems, vacuum chambers, and process heads—with minimal deflection, guaranteeing consistent performance across the entire work envelope.

Enabling True Scientific Discovery with Metrology

Beyond manufacturing, the unique characteristics of precision granite are indispensable in fundamental scientific research and metrology. A prime example is its role in high-resolution analytical instruments, particularly precision granite for XRD equipment (X-ray Diffraction).

X-ray Diffraction is a powerful technique used to determine the atomic and molecular structure of a crystal. The precision required for the goniometer—the device that rotates the sample and the X-ray detector—is phenomenal. Any movement or vibration that affects the angle of incidence or detection can completely invalidate the complex data being collected.

The metrology platform of a high-end XRD system must be free from thermal drift and capable of supporting complex optical and mechanical assemblies with exceptional stability. Precision granite provides the perfectly flat and dimensionally inert reference plane necessary for achieving the angular resolutions required for advanced material analysis. Its non-magnetic properties are an added benefit, ensuring that sensitive electronic sensors and electromagnetic control systems within the equipment are not affected by residual magnetism, a common issue with ferrous metals.

The Unmatched Advantages of Natural Stone in the Precision Era

The success of granite in these demanding applications is not a coincidence; it is a direct result of its innate material science:

-

Dimensional Stability: After geological aging for millions of years, the internal structure of high-quality black granite is uniform and stress-relieved, providing virtually zero internal movement over time, which is crucial for maintaining calibration.

-

Low Thermal Expansion: Its minimal reaction to temperature changes maintains geometry, a property vital for all precision processes operating in controlled, yet not perfectly isothermal, conditions.

-

Vibration Damping: The natural mineral composition provides outstanding inherent damping, suppressing mechanical noise faster and more effectively than engineered metals.

-

Non-Corrosive and Non-Magnetic: Granite is rust-proof and non-magnetic, simplifying maintenance and eliminating electromagnetic interference issues that can plague sensitive instrumentation.

By leveraging these properties, manufacturers can achieve the micron- and nanometer-level tolerances necessary to propel the next wave of technological innovation. The move from traditional metal bases to custom-engineered, ultra-flat granite foundations represents a fundamental shift in high-precision engineering—a recognition that for true stability, sometimes the oldest materials are the best. For any company committed to achieving unparalleled accuracy in a-Si, LTPS, or advanced metrology equipment, precision granite is not just a material choice; it is a competitive necessity.

Post time: Dec-03-2025