When designing a granite precision platform, one of the most frequently asked questions from engineers and equipment manufacturers is whether the mounting holes can be customized — and how they should be arranged to ensure both functionality and precision.

The short answer is yes — mounting holes in a granite platform can be fully customized according to the mechanical structure and installation requirements of the equipment. However, the layout must follow specific engineering and metrology principles to maintain the platform’s stability and accuracy.

Customization Possibilities

ZHHIMG® provides complete flexibility in mounting hole size, type, and position. Options include:

-

Threaded inserts (stainless steel or bronze)

-

Through holes for bolts or dowel pins

-

Counterbored holes for hidden fasteners

-

Air hole channels for air-bearing systems or vacuum clamping

Each hole is precision-machined on CNC granite processing centers under constant temperature and humidity conditions, ensuring micron-level positioning accuracy and perfect alignment with the design drawing.

Design Principles for Hole Layout

Proper layout of mounting holes is essential to preserve both the structural strength and dimensional stability of the granite platform. The following principles are recommended:

-

Avoid stress concentration: Holes should not be too close to the platform edges or near large cutouts, which can weaken structural integrity.

-

Symmetrical distribution: A balanced layout minimizes internal stress and maintains uniform support.

-

Maintain flatness tolerance: Hole positioning must not affect the reference surface’s flatness or measurement performance.

-

Match equipment interface: The hole spacing and depth must align precisely with the customer’s equipment base or guide rail system.

-

Consider future maintenance: Hole positions should allow easy cleaning and replacement of inserts when needed.

Each design is verified through finite element analysis (FEA) and measurement simulation, ensuring that the final platform achieves optimal stiffness and accuracy.

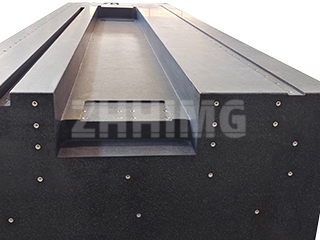

ZHHIMG® Manufacturing Advantage

ZHHIMG® is one of the few global manufacturers capable of producing granite structures up to 20 meters in length and 100 tons in weight, with integrated customized mounting holes. Our engineering team combines decades of metrology experience with modern processing technology to ensure every detail meets DIN, JIS, ASME, and GB standards.

All granite materials used are ZHHIMG® Black Granite (density ≈3100 kg/m³), known for exceptional hardness, thermal stability, and vibration damping. Each platform is calibrated using Renishaw® laser interferometers and WYLER® electronic levels, traceable to national metrology institutes.

Post time: Oct-16-2025