In the pursuit of the next generation of semiconductor manufacturing and sub-micron metrology, the “foundation” and the “path” are the two most critical variables. As machine designers strive for higher throughput and nanometer-level repeatability, the choice between a granite air bearing guide and a traditional roller bearing guide has become a pivotal engineering decision. Furthermore, the material of the machine base itself—comparing granite and high-performance ceramics—dictates the thermal and vibrational limits of the entire system.

Comparing Granite Air Bearing Guides and Roller Bearing Guides

The fundamental difference between these two systems lies in their method of supporting the load and managing friction.

Granite Air Bearing Guides represent the peak of frictionless motion. By utilizing a thin film of compressed air—typically between 5 to 20 microns—the moving carriage is literally floated above the granite guide rail.

-

Zero Friction and Wear: Because there is no physical contact, there is no “stiction” (static friction) to overcome, and the system never wears down. This allows for incredibly smooth, constant-velocity scanning.

-

Error Averaging: One of the most significant advantages of air bearings is their ability to “average” out the microscopic surface finish irregularities of the granite rail, leading to straighter motion than the rail itself.

-

Cleanliness: Without the need for lubrication, these guides are inherently cleanroom-compatible, making them the standard for wafer inspection and flat panel display production.

Roller Bearing Guides, conversely, rely on the physical contact of high-precision steel rollers or balls.

-

Superior Load Capacity: For applications involving heavy payloads or high cutting forces (such as precision grinding), roller bearings offer significantly higher stiffness and load-bearing capacity.

-

Operational Simplicity: Unlike air bearings, which require a constant, ultra-clean compressed air supply and filtration systems, roller bearings are “plug-and-play.”

-

Compact Design: Mechanical bearings can often support higher loads in a smaller footprint compared to the larger surface area required for an effective air bearing pad.

While roller bearings are robust and cost-effective for general precision, air bearings are the non-negotiable choice for applications where “contact” is the enemy of accuracy.

Applications of Air Bearing Guides: Where Precision Meets Fluidity

The adoption of air bearing guides has expanded beyond the laboratory into high-volume industrial production.

In the Semiconductor Industry, air bearings are used in lithography and wafer probing. The ability to move at high speeds with zero vibration ensures that the scanning process does not introduce artifacts into the nanometer-scale circuitry.

In Digital Imaging and Large-Format Scanning, the constant velocity of an air bearing is crucial. Any “cogging” or vibration from a mechanical bearing would result in “banding” or distortion in the final high-resolution image.

Coordinate Measuring Machines (CMM) rely on granite air bearing guides to ensure that the probe can move with the lightest possible touch. The lack of friction allows the machine’s control system to respond instantly to the most minute surface changes of the part being measured.

The Material Foundation: Granite vs. Ceramic for Machine Bases

The performance of any guide system is limited by the stability of the base it is mounted on. For decades, granite has been the industry standard, but advanced ceramics (such as Alumina or Silicon Carbide) are carving out a niche in extreme-performance applications.

Granite Machine Bases remain the preferred choice for 90% of high-precision applications.

-

Damping Properties: Granite is naturally superior at absorbing high-frequency vibrations, which is essential for metrology.

-

Cost-Effectiveness: For large-scale bases (up to several meters), granite is significantly more economical to source and process than technical ceramics.

-

Thermal Inertia: Granite’s high mass means it reacts slowly to ambient temperature changes, providing a stable environment for long-duration measurements.

Ceramic Machine Bases (specifically Alumina) are utilized when the “ultimate” performance is required.

-

High Stiffness-to-Weight Ratio: Ceramics are much stiffer than granite for the same weight. This allows for higher acceleration and deceleration of the moving stages without deforming the base.

-

Extreme Thermal Stability: Some ceramics have a coefficient of thermal expansion (CTE) even lower than granite, and their higher thermal conductivity allows the base to reach thermal equilibrium faster.

-

Hardness: Ceramics are virtually scratch-proof and resistant to chemical erosion, though they are more brittle and significantly more expensive to manufacture in large formats.

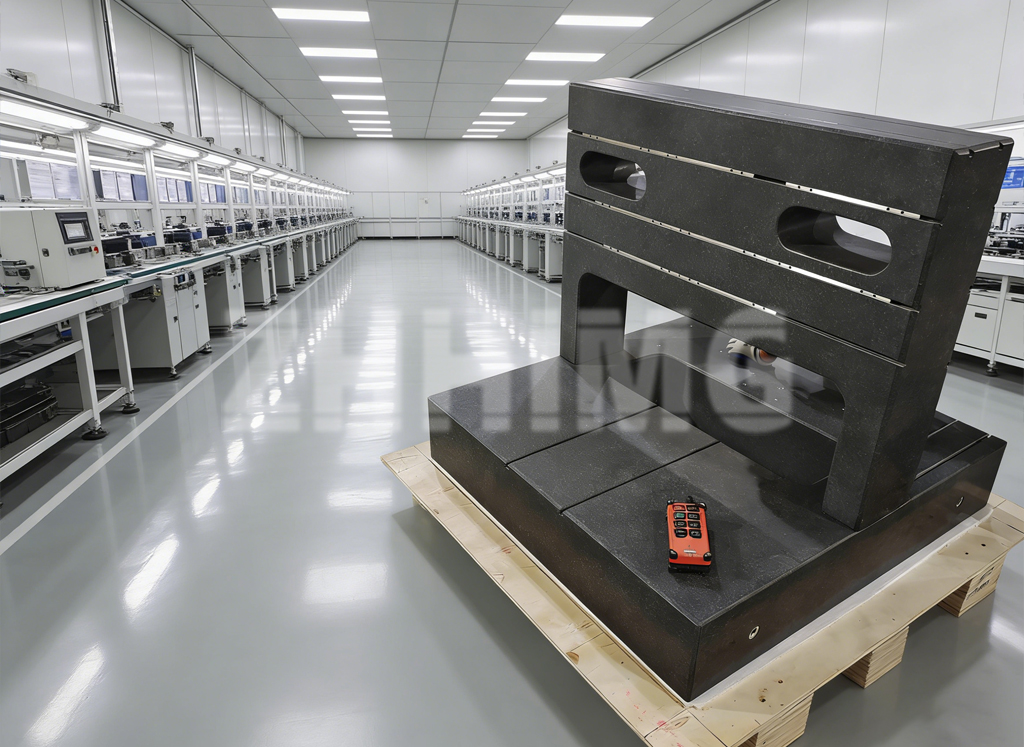

The ZHHIMG Commitment to Material Science

At ZHHIMG, we believe that the best solution is rarely a one-size-fits-all approach. Our engineering team specializes in the hybrid integration of these technologies. We often utilize the vibration-damping mass of a granite base to support the frictionless motion of an air bearing guide, sometimes incorporating ceramic inserts at critical high-wear or high-stiffness points.

As a leading manufacturer, we provide the global market with the geological certainty of premium-grade granite and the technical sophistication of modern motion systems. Our manufacturing facility combines traditional hand-lapping expertise—a skill required to achieve the flatnesses necessary for air bearings—with state-of-the-art CNC machining and laser interferometry.

Conclusion: Engineering Your Success

The choice between granite and ceramic, or between air and mechanical bearings, ultimately dictates the operational limits of your technology. For engineers in the aerospace, semiconductor, and metrology sectors, understanding these trade-offs is the key to innovation. ZHHIMG Group continues to push the boundaries of what is possible in precision motion, ensuring that your machine stands on a foundation of absolute stability and moves with unparalleled accuracy.

Post time: Jan-22-2026