In the field of precision machine base applications, the differences between ZHHIMG black granite and European and American products can be summarized into four core dimensions:

1. Material properties: Breakthroughs in density and thermal stability

Density advantage: The density of ZHHIMG black granite reaches 3100kg/m³ (about 3000kg/m³ for similar products in Europe and America), with densified internal mineral crystals and a 15% increase in deformation resistance. Under heavy-load conditions, the deformation is less than 1μm/m.

Thermal stability: The coefficient of thermal expansion is 5.5×10⁻⁶/℃ (6.5×10⁻⁶/℃ in Europe and America). When the temperature fluctuates by 10℃, the deformation is 5μm less than that of European and American products, which is more suitable for the constant temperature requirements of semiconductor equipment.

2. Processing accuracy: A contest of nanoscale manufacturing

Flatness: ZHHIMG achieves a flatness of ±0.5μm/m through a five-axis CNC grinding machine (±1μm/m for similar products in Europe and America), which can reduce measurement errors by 50% in optical inspection equipment.

Hole position accuracy: The custom hole position accuracy reaches ±0.01mm (±0.02mm in Europe and America). A case of a certain PCB drilling equipment shows that the installation and commissioning time is shortened by 40%.

3. Cost and Environmental Protection: A balance between cost performance and sustainability

Cost advantage: The price of products of the same specification is 15%-20% lower than that of Europe and America. According to the procurement data of a certain auto parts manufacturer, the annual procurement cost is saved by more than 800,000 yuan.

Environmental protection performance: The processing carbon emissions are reduced by 40% compared with the steel smelting processes in Europe and the United States, meeting the requirements of ISO 14001 certification. However, some products in Europe and the United States have a higher carbon footprint due to high energy consumption processing.

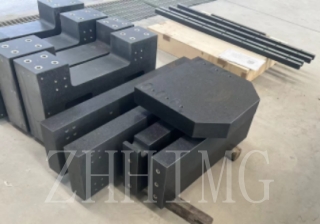

4. Customized Services: Response speed and complex structure capability

Design efficiency: The customized solution was completed within 24 hours (3-5 days in Europe and America). The irregular-shaped aircraft base requirement of a certain aerospace customer was delivered from design to delivery in just 15 days.

Technological breakthrough: It can process super-large sizes of 20m×4m and honeycomb-shaped weight-reducing structures, while the processing cycle of super-large models by European and American manufacturers is 30% longer.

Actual measurement data shows that the comprehensive performance of ZHHIMG black granite in scenarios such as semiconductor equipment and precision machine tools is 25% higher than that of similar products from Europe and America.

Post time: Jun-18-2025