When selecting a precision platform for industrial applications, the material chosen plays a critical role in determining both performance and cost. Granite precision platforms, cast iron platforms, and ceramic platforms each have distinct advantages and drawbacks, making them suitable for different applications. From a cost perspective, the price differences between these materials can significantly influence purchasing decisions, especially in industries where precision is a top priority.

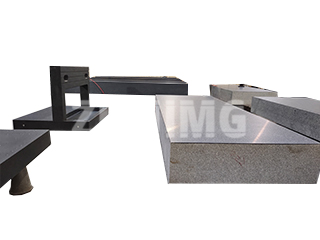

Granite precision platforms are widely regarded as one of the most stable and reliable options for high-precision measurement and machining. Granite, particularly ZHHIMG® Black Granite, is known for its exceptional physical properties, including its high density, low thermal expansion, and resistance to wear and deformation. The production process for granite platforms is complex and requires advanced equipment to achieve the high levels of precision required. This intricate manufacturing process, coupled with the superior material properties, makes granite platforms the most expensive of the three options. However, their long-term durability, minimal maintenance needs, and unparalleled accuracy make them a preferred choice in industries such as aerospace, semiconductor manufacturing, and high-precision measurement.

Cast iron platforms, while offering good stability and rigidity, are generally more affordable than granite platforms. Cast iron is easier to manufacture, and the material itself is less costly than granite or ceramic. While cast iron provides adequate support for many industrial applications, it is more prone to thermal expansion and may not maintain the same level of precision over time as granite platforms. Therefore, cast iron platforms are typically used in situations where cost is a primary concern, and the precision requirements are not as stringent. For applications where budget constraints exist, cast iron platforms are a viable and cost-effective option, offering a good balance of performance and price.

Ceramic platforms, made from materials like alumina (Al₂O₃), silicon carbide (SiC), or silicon nitride (Si₃N₄), are another option that provides excellent stability and precision. Ceramics are known for their high rigidity, wear resistance, and low thermal expansion, making them ideal for high-precision environments. However, the manufacturing process for ceramic platforms is highly specialized, and the materials themselves are often more expensive than cast iron. While ceramic platforms generally offer a price point between granite and cast iron, they are considered more cost-effective than granite for many precision applications, particularly in industries like semiconductor manufacturing, optical measuring systems, and high-tech electronics.

From a cost perspective, the ranking typically follows this order: Cast Iron Platforms are the least expensive, followed by Ceramic Platforms, with Granite Precision Platforms being the most costly. The choice between these materials depends on the specific needs of the application, such as the level of precision required, environmental factors, and the available budget.

For industries demanding the highest levels of precision, investing in granite or ceramic platforms may offer long-term benefits in terms of performance and durability. However, for applications where cost efficiency is more critical and the precision requirements are less demanding, cast iron platforms provide a viable solution without compromising too much on performance.

Post time: Oct-23-2025