In the world of high-precision manufacturing—where tolerances shrink below 5 microns and surface finishes approach optical quality—the tools we rely on must evolve beyond tradition. For decades, steel and granite ruled the metrology bench. But as industries like semiconductor equipment, aerospace optics, and medical micro-devices push into realms where even thermal drift or microscopic wear introduces unacceptable error, a new class of reference tools is emerging: those crafted not from metal or stone, but from advanced technical ceramics.

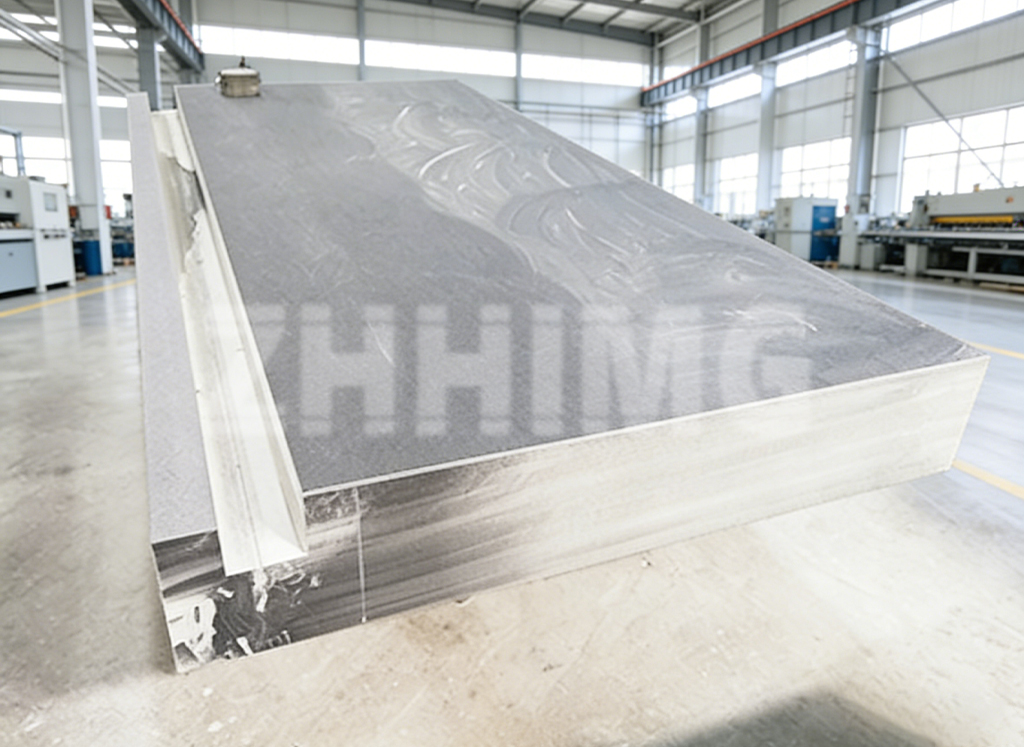

At ZHHIMG, we’ve moved beyond simply offering Ceramic Straight Ruler or Ceramic Square Ruler products. We’re redefining what a straight edge can be—by combining ultra-stable ceramic materials with cutting-edge design, including our groundbreaking Custom Ceramic air floating ruler, a solution that eliminates mechanical contact entirely while delivering nanometer-level repeatability.

Why ceramics? The answer starts at the molecular level. Unlike steel—which expands significantly with temperature—or granite—which, despite its stability, remains porous and heterogeneous—engineered ceramics like zirconia-toughened alumina (ZTA) and silicon nitride offer near-zero porosity, exceptional hardness (1400–1800 HV), and thermal expansion coefficients as low as 3–4 µm/m·°C. This means a Ceramic Straight Edge from ZHHIMG maintains its geometry across temperature swings that would distort conventional tools by several microns.

But material alone isn’t enough. What truly sets our ceramic rulers apart is the precision of their fabrication. Using diamond grinding, sub-aperture polishing, and laser interferometric validation in ISO Class 5 cleanrooms, we achieve straightness tolerances better than 0.8 µm over 500 mm—verified not just at delivery, but documented in full calibration reports traceable to NIST and PTB standards. Every Ceramic Square Ruler undergoes perpendicularity testing via electronic autocollimation, ensuring angles are held to within 1 arc-second (≈0.5 µm deviation at 100 mm).

These aren’t theoretical specs. They’re operational realities for clients who can no longer afford compromise. A leading EUV lithography component supplier now uses our Ceramic Straight Ruler exclusively for aligning mirror support frames. “Steel rulers warped during long exposure cycles,” their lead metrologist told us. “Granite picked up particles. The ceramic version? It’s been stable for 18 months—no recalibration needed.”

Yet even perfect geometry can be compromised by contact. Drag a ruler across a surface, and you risk micro-scratches, oil film interference, or elastic deformation—especially on soft metals or polished optics. That’s where ZHHIMG’s innovation leaps forward with the Custom Ceramic air floating ruler.

This isn’t just a ceramic straight edge with holes drilled in it. It’s a fully engineered aerostatic system, designed using computational fluid dynamics to deliver uniform, laminar airflow across the entire length of the ruler. When pressurized with clean, dry air (or nitrogen in sensitive environments), the ruler floats 5–10 microns above the workpiece—eliminating physical contact while maintaining perfect alignment. The result? True non-contact measurement for flatness, straightness, or step height verification, with repeatability down to ±0.2 µm.

One quantum computing lab in Switzerland now uses a 600-mm Custom Ceramic air floating ruler to inspect superconducting chip carriers. “Any contact—even with a soft stylus—introduces stress that alters qubit performance,” their process engineer explained. “The air-floating ceramic ruler gives us the reference we need without touching the part. It’s become mission-critical.”

What makes this possible is ZHHIMG’s unique integration of materials science, precision machining, and metrology expertise. While many suppliers treat ceramics as structural components, we optimize them as measurement artifacts. Our Ceramic Square Ruler designs include chamfered edges to prevent chipping, matte-finished backs to reduce glare under inspection lighting, and optional fiducial markers for automated vision systems. For cleanroom applications, surfaces are polished to Ra < 0.02 µm to minimize particle adhesion.

And because every application is different, we don’t believe in one-size-fits-all. Need a Ceramic Straight Edge with embedded vacuum channels to hold thin wafers during inspection? We’ve built it. Require a square ruler with through-holes aligned to your CMM probe tip? Done. Want a Custom Ceramic air floating ruler with integrated pressure sensors and digital leveling feedback? That’s already in beta testing with a Tier-1 aerospace client.

Industry recognition has followed. In the 2025 Global Advanced Metrology Review, ZHHIMG was cited as the only company offering a complete family of certified ceramic reference tools—including floating variants—with full geometric validation and digital traceability. But more importantly, adoption is accelerating: over 60% of our ceramic ruler orders now come from industries that previously considered such tools “overkill”—until they measured the difference.

A medical device startup producing neural implants switched from steel to our Ceramic Square Ruler and saw their first-pass yield jump by 22%. “The old square left micro-gouges on titanium housings,” their QA manager said. “We didn’t even realize it until we switched. Now, every part passes visual and dimensional checks on the first try.”

So as you evaluate your next metrology upgrade, ask yourself: Is my current straight edge adding uncertainty—or eliminating it?

If your process operates at the edge of detectability, the answer may lie in ceramics—not as a novelty, but as a necessity. At ZHHIMG, we don’t just manufacture Ceramic Straight Ruler, Ceramic Square Ruler, or Ceramic Straight Edge tools. We engineer confidence into every micron.

Post time: Dec-31-2025