In industries such as semiconductors and precision electronics, which have extremely strict requirements for the production environment, the cleanliness of the dust-free workshop directly affects the product yield rate. The pollution problem caused by rusting of traditional cast iron bases is becoming a difficult issue for enterprises. However, ZHHIMG's granite solution has successfully passed authoritative certification with its outstanding performance, bringing a new breakthrough to the industry.

Although cast iron bases are widely used in the industrial field, their poor corrosion resistance is fully exposed in the environment of dust-free workshops. Cast iron is mainly composed of iron and carbon, and it is highly prone to oxidation reactions with oxygen and moisture in the air, forming rust. In a dust-free workshop, even the slightest rust peeling off can produce iron filings. Once these particles enter precision equipment or adhere to the surface of products, they may cause serious consequences such as short circuits in semiconductor chips and contamination of precision optical components, significantly increasing the defect rate of products. According to industry statistics, product defect problems caused by rust pollution of cast iron bases account for 15% to 20% of production failures in dust-free workshops.

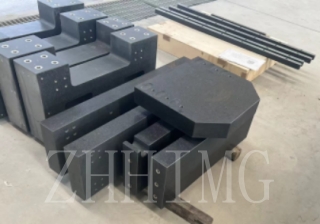

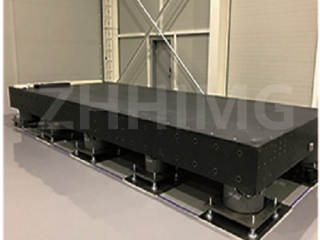

The ZHHIMG granite solution has fundamentally addressed the pollution risks of cast iron bases. Granite is mainly composed of minerals such as quartz and feldspar. It has extremely stable chemical properties, with a pH tolerance range of 1 to 14. It hardly reacts with common acidic or alkaline chemical reagents and does not undergo oxidation with oxygen or moisture in the air. Therefore, there is no problem of rusting. Meanwhile, its dense structure (porosity < 0.1%) makes its surface smooth and flat, and it is not easy to adsorb dust and contaminants. Even when used for a long time in a dust-free workshop environment with high cleanliness requirements, it can still maintain a clean state, effectively avoiding the adverse effects on the product caused by base contamination.

What is more worthy of attention is that the ZHHIMG granite solution has passed the ISO 14644-1 Class 5 cleanroom environmental certification. This certification has strict standard requirements for the concentration of suspended particles in the air. During the three consecutive months of rigorous tests, the ZHHIMG granite base consistently maintained an extremely low particle release rate, ensuring that it would not cause pollution to the dust-free workshop environment. In addition, the granite platform also features an extremely low coefficient of thermal expansion and excellent vibration resistance. While ensuring the cleanliness of the dust-free workshop, it can provide stable support for precision equipment, enhancing the operational accuracy and reliability of the equipment.

After a well-known semiconductor manufacturing enterprise adopted the ZHHIMG granite solution to replace the cast iron base, the defect rate of its products caused by pollution dropped sharply from 8% to 1.5%, production efficiency increased by 25%, and the annual cost saved due to product scrapping exceeded 10 million yuan. This remarkable achievement fully validates the outstanding value of ZHHIMG's granite solution in addressing pollution issues in dust-free workshops.

With the continuous improvement of product precision and quality requirements in various industries, the importance of dust-free workshops is becoming increasingly prominent. ZHHIMG granite solutions, with their rust-proof, clean and stable features, as well as authoritative certification backing, offer reliable base options for enterprises, helping the industry move towards higher precision and quality manufacturing.

Post time: May-23-2025