In high-end industrial fields such as precision manufacturing and semiconductor processing, the stability of production equipment directly determines the quality of products and production efficiency. However, traditional cast iron bases are prone to thermal deformation problems when operating for a long time or when the environmental temperature changes, resulting in increased costs and reduced customer trust. According to industry research data, the defect rate of products caused by the thermal deformation of cast iron bases can even reach over 30% in some temperature-sensitive production processes, seriously restricting the development of enterprises.

The root cause of the thermal deformation problem of cast iron bases lies in their material properties. The coefficient of thermal expansion of cast iron is relatively high. When the equipment operates for a long time and generates heat, or when the ambient temperature fluctuates, the cast iron base will undergo uncontrollable dimensional changes. Such minor deformations, in precision processing scenarios, are sufficient to lead to a series of serious consequences such as processing accuracy deviation, etching pattern distortion, and assembly errors of components, ultimately resulting in a large number of products becoming scrap due to failure to meet quality standards.

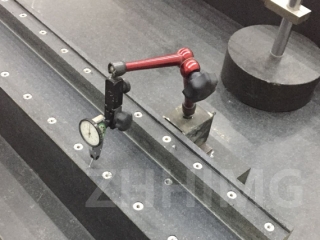

In response to this industry pain point, the ZHHIMG granite etching platform emerged, providing enterprises with a breakthrough thermal stability solution. The ZHHIMG granite etching platform is made of natural granite, which has a unique advantage in thermal stability. The coefficient of thermal expansion of granite is extremely low, only 1/5 to 1/10 that of cast iron. It can maintain a high degree of dimensional stability in an environment with drastic temperature changes, effectively avoiding processing errors caused by thermal deformation. Whether it is a high-temperature production workshop or a working environment with a large temperature difference between day and night, the ZHHIMG granite etching platform can ensure the high-precision operation of the equipment and fundamentally improve the product yield.

In addition to its outstanding thermal stability, the ZHHIMG granite etching platform also boasts numerous advantages. It has high hardness and strong wear resistance, can withstand high-intensity processing loads, and its service life is much longer than that of cast iron bases. Natural granite material has excellent shock absorption performance, which can effectively absorb the vibrations generated during equipment operation and further ensure processing accuracy. Meanwhile, the surface of the platform has undergone precise grinding treatment, with a flatness that can reach the micrometer level, providing a solid and reliable foundation for precision processing.

Numerous practical application cases of enterprises have fully verified the outstanding performance of the ZHHIMG granite etching platform. After introducing the ZHHIMG granite etching platform, the defect rate of a certain semiconductor manufacturing enterprise dropped sharply from the original 25% to within 5%, the production efficiency increased by 30%, the production cost was significantly reduced, and the market competitiveness was notably enhanced.

If your enterprise is also troubled by the yield problem caused by the thermal deformation of cast iron bases, the ZHHIMG granite etching platform is undoubtedly your ideal choice. With its stable and reliable performance, it will help you break through production bottlenecks and achieve a dual improvement in product quality and production efficiency.

Post time: May-14-2025