In recent years, the industrial metrology community has started paying closer attention to a seemingly minor feature of granite precision surface plates: edge chamfering. While flatness, thickness, and load capacity have traditionally dominated discussions, experts are now emphasizing that the edges of these high-precision tools can significantly impact safety, durability, and usability.

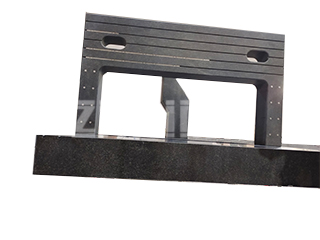

Granite precision surface plates serve as the backbone of industrial measurement, providing stable and accurate reference surfaces. The edges of these plates, if left sharp, pose risks during handling and transportation. Reports from several manufacturing workshops indicate that chamfered edges—small beveled or rounded corners—have helped reduce accidents and minimize damage to the plates themselves.

Industry professionals note that chamfering is more than a safety measure. “A chamfered edge protects the integrity of the granite,” said a leading metrology engineer. “Even a minor corner chip can compromise the plate’s lifespan and, in high-precision applications, may affect measurement reliability.”

Common chamfer specifications, such as R2 and R3, are now standard in many workshops. R2 refers to a 2mm radius along the edge, typically applied to smaller plates or those used in low-movement environments. R3, a 3mm radius, is preferred for larger, heavier plates that undergo frequent handling. Experts recommend selecting the chamfer size based on plate dimensions, handling frequency, and workplace safety requirements.

Recent surveys in industrial labs indicate that plates with chamfered edges experience fewer accidental damages and reduced maintenance costs. Beyond durability, chamfered edges also improve ergonomics during lifting and installation, ensuring smoother workflow in busy production lines.

Safety authorities have begun incorporating chamfer guidelines into internal standards. In several European and North American factories, chamfered edges are now a recommended practice for all granite surface plates exceeding certain dimensions.

While some may consider edge chamfering a minor detail, manufacturers emphasize its growing importance in modern metrology. As industrial processes demand both precision and efficiency, attention to features like edge chamfers can make a measurable difference.

Analysts predict that as the metrology industry continues to evolve, the discussion around plate edges will expand. Research suggests that combining chamfered edges with other protective features, such as proper handling fixtures and storage supports, contributes significantly to the longevity and reliability of granite precision plates.

In conclusion, chamfering—once a minor detail—has emerged as a key design feature in the production and maintenance of granite precision surface plates. Whether choosing an R2 or R3 chamfer, industrial users are finding that the small adjustment can provide tangible benefits in safety, durability, and operational efficiency.

Post time: Sep-25-2025