In the production process of lithium-ion batteries, the coating process, as a key link, directly affects the performance and safety of the batteries. The stability of the motion control platform of the lithium battery coating machine plays a decisive role in the coating accuracy. Granite and cast iron, as commonly used platform materials, the difference in their dimensional stability has attracted much attention. This article will deeply analyze the significant improvement in dimensional stability of granite compared to cast iron on the motion control platform of lithium battery coating machines through material properties, experimental data and practical application cases.

Material properties determine the basis of stability

Cast iron, as a traditional industrial material, was once widely used in the field of motion control platforms due to its excellent casting performance and cost advantages. However, cast iron materials have inherent defects. Its internal structure contains a large amount of flake graphite, which is equivalent to internal cracks and will reduce the overall rigidity of the material. Meanwhile, the coefficient of thermal expansion of cast iron is relatively high, approximately 10-12 ×10⁻⁶/℃. Under the accumulation of heat generated by the long-term operation of lithium battery coating, it is prone to thermal deformation. In addition, there is casting stress inside cast iron. Over time, the release of stress will cause irreversible changes in the platform size, affecting the coating accuracy.

Granite is a natural material formed through geological processes over hundreds of millions of years. Its internal crystal structure is dense and uniform, and it has inherent high stability. The linear expansion coefficient of granite is only 0.5-8×10⁻⁶/℃, which is 1/2-1/3 of that of cast iron, and it is extremely insensitive to temperature changes. Meanwhile, granite is hard in texture, with a compressive strength as high as 1,050-14,000 kilograms per square centimeter. It can effectively resist external force impacts and vibrations, providing a solid and stable foundation for the motion control platform. There is almost no residual stress inside it, and it will not cause dimensional changes due to stress release, ensuring the dimensional stability of the platform from the essence of the material.

Experimental data verify the performance differences

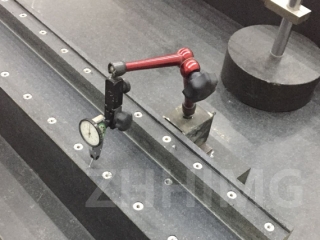

To visually compare the differences in dimensional stability between granite and cast iron, the research team carried out a special experiment. Two motion control platforms of the lithium battery coating machine of the same specification were selected, made of granite and cast iron respectively, and tested under the same environmental conditions. The experiment simulated the actual working scenario of the lithium battery coating machine. By continuously running the equipment, the size changes of the platform at different time points were monitored.

The experimental results show that after continuous operation for 24 hours, due to the heat generated by the operation of the equipment, the surface temperature of the cast iron material platform increased by approximately 15℃, resulting in an increase of 0.03mm in the length direction dimension of the platform. Under the same conditions, the size variation of the granite platform is almost negligible, and its size fluctuation range is less than 0.005mm. After 1000 hours of long-term aging tests, due to the release of internal stress and the accumulation of thermal deformation, the flatness error of the cast iron platform expanded from the initial 0.01mm to 0.05mm. The flatness error of the granite platform is always kept within 0.015mm, and the advantage of dimensional stability is obvious.

Remarkable achievements in practical applications

In the actual production of a large lithium battery manufacturing enterprise, cast iron motion control platforms were once used. As the operating time of the equipment increased, the coating accuracy gradually declined, resulting in uneven coating thickness, poor consistency of battery electrode sheets, and a defective product rate as high as 8%. To solve this problem, the enterprise replaced the motion control platforms of some equipment with granite materials.

After replacement, the dimensional stability of the equipment has been significantly improved. During a six-month production cycle, the coating machine using a granite platform always kept the coating thickness error within ±2μm, and the defective product rate was significantly reduced to less than 3%. Meanwhile, as granite platforms do not require as frequent precision calibration and maintenance as cast iron platforms, they save enterprises a significant amount of equipment maintenance costs and downtime every year, and increase production efficiency by more than 15%.

In conclusion, in the application of the motion control platform of lithium battery coating machines, granite, with its outstanding material properties, significantly outperforms cast iron in terms of dimensional stability. Whether from the perspective of material nature, experimental data, or practical application effects, granite provides a reliable guarantee for the high-precision and stable production of lithium battery coating processes. With the continuous improvement of product quality requirements in the lithium battery industry, motion control platforms made of granite are bound to become the mainstream choice in the industry.

Post time: May-22-2025