In the heart of the machinery manufacturing and metrology industries lies a foundational tool: the Cast Iron Surface Plate. These planar reference instruments are indispensable for accurate workpiece inspection, precise scribing, and serving as stable benchmarks for machine tool setup. At ZHHIMG®, our commitment to ultra-precision extends beyond our renowned granite products to the rigorous standards governing all essential metrology tools. Understanding the meticulous process—from casting to installation—is paramount to ensuring the quality and longevity of this critical shop floor asset.

The Foundry Discipline: Precautions in Cast Iron Casting

The manufacturing of high-quality cast iron surface plates begins with extreme discipline in the foundry. Operators must adhere strictly to a controlled process flow aimed at simplicity and uniformity. This involves designing patterns that minimize the number of parting surfaces and sand cores while ensuring optimal draft angles and smoothly transitioning wall thicknesses. Selecting a suitable gating system is crucial; it must ensure sequential solidification, leading to a uniformly structured, stress-minimized casting.

Crucially, the quality of the molding sand directly influences the final casting. The sand mixture must possess excellent permeability, wet strength, fluidity, plasticity, and collapsibility. This is achieved by strictly following the material feeding sequence—old sand, new sand, clay, coal powder, and water—and controlling the mixing time precisely at six to seven minutes. The mixed sand is then rested and sieved to enhance its permeability and fluidity before use.

The pouring process itself demands unwavering focus. Molten metal must be properly inoculated and thoroughly de-slagged before pouring commences. A continuous and stable flow is essential to prevent defects such as sand erosion and the formation of sand holes. Prompt reaction to any leakage is necessary to avoid serious defects like cold shuts and incomplete pouring. Finally, a meticulous cleaning process ensures the cooled casting is removed from the mold without damage, yielding a surface free of initial defects.

Design, Defects, and Density: Ensuring Structural Integrity

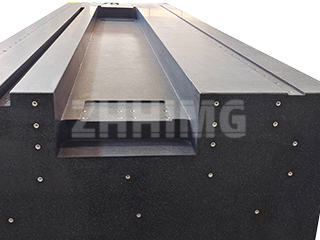

A high-quality cast iron platform is engineered to endure. Generally designed as either single-sided or box-type structures, their working surfaces are commonly square or rectangular. The structural integrity is heavily dependent on features like sidewalls and reinforcing ribs, which must be dimensioned precisely based on the required load-bearing capacity and precision grade. The height of these reinforcing ribs—whether half-rib, full-rib, or flat-rib—provides the necessary tension and support.

Even with the most rigorous casting controls, slight defects may occur. For platforms below accuracy Grade “0,” industry standards permit the remedial plugging of minor sand holes (diameter less than 14 mm) using the same material, provided the repair material’s hardness is lower than the surrounding iron. However, the working surface must ultimately be free of major flaws, including cracks, porosity, slag inclusions, and shrinkage cavities, and the casting surface must be smooth with firmly adhered paint. Choosing a platform that has undergone natural aging or artificial heat treatment is paramount, as these processes reduce internal stress and prevent future diagonal deformation.

Installation and Maintenance: Preserving Precision

A cast iron platform, regardless of its quality, is only as accurate as its installation. It must be horizontally leveled with the load distributed evenly across all support points, typically achieved using the adjustable feet of a supporting bracket. This leveling process, guided by a high-precision electronic level or frame level, is crucial for achieving its rated accuracy.

To maintain precision, the environment is key. The working temperature should be maintained around 20℃(± 5℃), and vibration must be strictly avoided. Before any work begins, the surface must be meticulously cleaned to remove residual sand, burrs, oil, and rust, as even minor contaminants compromise accuracy. A high micro-quality, or smooth surface, is vital for longevity.

With proper use and meticulous storage—avoiding humid, corrosive, or extreme temperature environments—a cast iron platform’s working surface precision can be maintained for two or more years. The platform structure itself can last for decades. Should the precision decline, it can be fully restored through expert adjustment or resurfacing (scraping). Regular inspection against its calibration standard is mandatory, as using a substandard plate will inevitably lead to measurement deviations and affect final product quality.

As a fundamental tool in the automotive, aerospace, instrument, and heavy machinery sectors, the cast iron platform is a testament to the fact that precision is built from the ground up.

Post time: Oct-31-2025