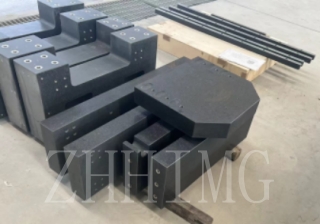

At present, with the vigorous development of the solar photovoltaic industry, the performance and stability of solar etching equipment play a crucial role in the production of high-efficiency photovoltaic cells. The granite base, with its outstanding corrosion resistance and anti-aging properties, has become an indispensable core component of solar etching equipment.

Resist strong acid and alkali corrosion and safeguard the purity of the etching process

During the solar etching process, highly corrosive chemical reagents such as hydrofluoric acid and nitric acid are used, which have a great corrosive effect on the components of the equipment. Ordinary metal or other material bases are prone to corrosion and rust after long-term contact with such chemical substances. This not only contaminates the etching solution but also affects the accuracy and stability of the equipment.

Granite is mainly composed of minerals such as quartz and feldspar, and its chemical properties are extremely stable. When facing the strong acid and alkali environment in the etching process, the granite base can effectively resist corrosion. According to data from professional testing institutions, when the granite base is immersed in a 20% hydrofluoric acid solution for 24 hours, the surface corrosion thickness is only 0.001mm, which is almost negligible. This excellent corrosion resistance ensures that the purity of the etching solution will not be affected by the corrosion of the base during the long-term use of the etching equipment, thereby guaranteeing the stability and consistency of the etching process and improving the yield rate of photovoltaic cells.

It has excellent anti-aging performance and can extend the service life of equipment

During the production process of solar etching equipment, it not only has to endure the erosion of chemical reagents, but also experience frequent temperature changes and mechanical vibrations. Ordinary materials, under the long-term effect of thermal expansion and contraction and mechanical stress, are prone to problems such as aging and deformation, leading to a decline in equipment accuracy and even the need to replace components or the entire machine in advance.

Granite has a dense and uniform internal structure, and its mineral crystals are closely combined with each other. Under normal usage conditions, even after several decades, the physical properties of the granite base will not change significantly. Its anti-aging performance enables solar etching equipment to maintain high precision and stability for a long time. For instance, a certain photovoltaic enterprise used etching equipment equipped with a granite base. After continuous operation for 15 years, the positioning accuracy of the equipment could still be maintained within ±0.05mm, which was almost the same as the accuracy when the equipment was first put into use. Compared with the equipment using ordinary material bases, the maintenance cycle is extended by 2 to 3 times, the service life of the equipment is significantly improved, and a large amount of equipment replacement and maintenance costs are saved for enterprises.

Stable performance guarantee helps the photovoltaic industry reduce costs and increase efficiency

The corrosion resistance and anti-aging properties of the granite base provide stable and reliable performance guarantees for solar etching equipment. Stable equipment performance means higher production efficiency and lower scrap rate. Take a production line with an annual capacity of 500MW of photovoltaic cells as an example. The etching equipment with a granite base can reduce the downtime for maintenance caused by equipment corrosion and aging by about 100 hours each year, and increase the value of photovoltaic cell modules produced by about 2 million yuan. Meanwhile, due to the more stable etching process, the product yield rate has increased by 2 to 3 percentage points, further reducing the production cost.

Under the backdrop of the solar photovoltaic industry's pursuit of grid parity and cost reduction and efficiency improvement, granite bases, with their excellent properties of corrosion resistance and anti-aging, have become the key to enhancing the performance and reducing costs of solar etching equipment. It not only provides a solid guarantee for the high-quality production of photovoltaic cells, but also contributes to the sustainable development of the entire photovoltaic industry

Post time: May-21-2025