In the field of semiconductor wafer grooving, precision is the lifeline. An unremarkable granite base can bring about a qualitative leap in the performance of the grooving equipment! What "superpowers" does it actually hide? Why is it said that choosing the right granite base means you have succeeded halfway? Today, we'll take you to reveal it in depth!

I. Inherent Strength: The Three "Inherent Advantages" of Granite

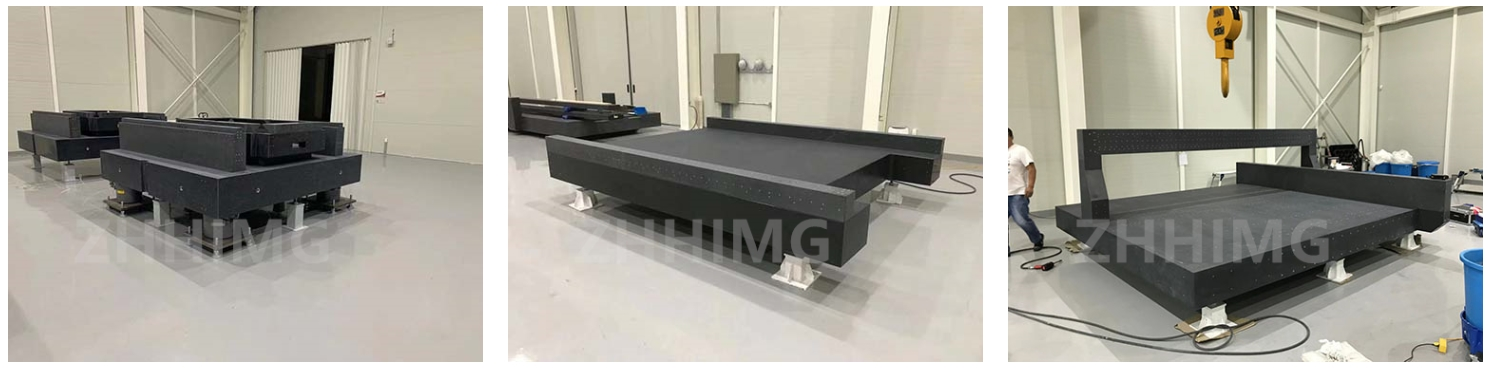

The seismic resistance is as stable as Mount Tai

Granite has a density as high as 2,800-3,100 kg/m³, and its structure is as dense as a "stone fortress". In the high-frequency vibration environment of wafer grooving (the equipment grooves over 100 times per minute), it can absorb more than 90% of the vibration energy, just like equipping the equipment with "shock-absorbing black technology"! The measured data from a certain chip factory shows that after using the granite base, the jitter amplitude of the grooving cutter head has decreased from 15μm to 3μm, and the edges of the micro-grooves carved are as smooth as a mirror.

2. "Heat-resistant constitution" Unafraid of temperature differences

Ordinary materials "expand and deform" when heated and "contract and deform" when cooled, but the thermal expansion coefficient of granite is as low as 4-8×10⁻⁶/℃, which is only 1/5 of that of metals! Even if the temperature in the workshop fluctuates sharply by 10℃ within 24 hours, its deformation is less than 0.01mm and can almost be ignored. This means that regardless of the alternation of day and night or the prolonged operation and heat generation of the equipment, the granite base can keep the slot position "motionless" all the time.

3. Indestructible wear resistance

The Mohs hardness of granite reaches 6 to 7, comparable to that of quartz stone, and its wear resistance is three times that of ordinary steel! Under the long-term high-frequency friction of the wafer grooving, the surface of the base hardly wears out. After a certain foundry used granite bases for five years, the flatness was still maintained within ±0.5μm/m upon inspection, and the grooving accuracy remained consistent, saving a significant amount of equipment calibration and replacement costs.

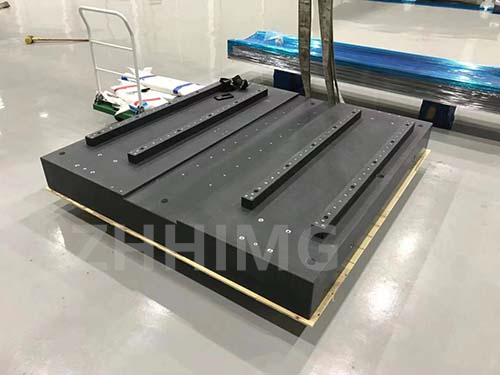

Ii. Precise Adaptation: How does Granite Meet Different grooving Requirements?

Scene 1: Ultra-fine grooving (micro-grooves under 10μm)

Requirement: Ultimate flatness

Granite advantages: Through five-axis linkage high-precision processing, the flatness can be controlled within ±0.5μm/m, which means that on a length of 1 meter, the height error is 200 times thinner than a human hair! Ensure that the distance between the grooving cutter head and the wafer is always precise, and the width error of the micro-grooves carved does not exceed ±0.1μm.

Scene 2: High-speed mass production grooving

Requirement: Super shock absorption performance

Advantages of granite: Its natural damping properties inside can quickly attenuate equipment vibration. After a certain panel factory introduced granite bases, the grooving speed increased by 40%, and the yield rate jumped from 85% to 96%, achieving a double harvest of production efficiency and quality!

Scene 3: Complex Environment grooving (High temperature/corrosion)

Requirements: High temperature resistance and corrosion resistance

Advantages of granite: Extremely strong chemical stability, resistant to acid and alkali corrosion; It has a low coefficient of thermal expansion and will not deform even at the local high temperature (150℃) during laser grooving. A granite base used in a certain laboratory with corrosive grooving solution has been in continuous use for three years, and the surface of the base remains intact.

Iii. How to Pick a "Genuine High-quality" Granite Base?

Look at the density: Granite with a density of ≥2800kg/m³ has a more compact structure.

Check certifications: Make sure to recognize authoritative certifications such as ISO 9001 and CNAS to ensure quality.

Verification data: The manufacturer is required to provide test reports on the coefficient of thermal expansion (< 8×10⁻⁶/℃) and flatness (±0.5μm/m).

On-site test: Tap the base. A clear sound indicates that there are no cracks inside. If the touch surface is as smooth as a mirror, it indicates high processing accuracy.

Conclusion: Choose the right granite and win half the battle in grooving!

From shock resistance, heat resistance to wear resistance, the granite base, with its "natural beauty" and "hardcore strength", has become the golden partner for wafer grooving equipment. In today's semiconductor manufacturing era that pursues nanoscale precision, a high-quality granite base is not only an investment in equipment but also a long-term guarantee for production efficiency and product quality!

Post time: Jun-17-2025