In the field of PCB (Printed Circuit Board) manufacturing, the drilling accuracy directly determines the electrical performance and yield rate of the circuit board. From mobile phone chips to aerospace circuit boards, the accuracy of every micron-level aperture is crucial to the success or failure of the product. Granite bases, with their unique material properties and structural advantages, are becoming the "golden partner" of PCB drilling equipment, driving the industry's precision to a new height.

I. Inherent Advantage: Stable performance lays the foundation for precision

Outstanding thermal stability

During the PCB drilling process, the heat generated by the high-speed rotation of the drill bit can reach 60-80℃. The expansion of ordinary metal materials due to heat can easily cause the drilling position to shift. The coefficient of thermal expansion of granite is only 4-8×10⁻⁶/℃, which is only 1/5 of that of steel. This means that even if the ambient temperature fluctuates sharply, the deformation of the granite base can be ignored. After a certain circuit board manufacturer adopted a granite base, the error of the drilling position was reduced from ±50μm to ±10μm, significantly improving the consistency of the electrical performance of the circuit board.

2. Super strong seismic performance

The high-frequency vibration of the drilling machine at thousands of revolutions per minute can affect the verticality of the drill bit, resulting in hole diameter deviations. The natural damping properties within granite enable it to absorb over 90% of the equipment vibrations (20-50Hz). The measured data show that after installing the granite base, the vibration amplitude of the drill bit decreased from 15μm to 3μm, and the Ra value of the roughness of the drilled hole wall decreased by 60%, significantly reducing the burrs and delamination problems of the hole wall.

3. Long-lasting wear resistance

PCB drilling is a high-frequency operation and has extremely high requirements for the wear resistance of the base surface. Granite has a Mohs hardness of 6 to 7 and its wear resistance is three times that of ordinary steel. A large PCB factory has continuously used granite bases for three years. The surface wear is less than 0.01mm. Compared with metal bases, the replacement cycle is extended by twice, effectively reducing the equipment maintenance cost.

Ii. Process Upgrade: Customized design enhances production efficiency

Modern granite bases, through precise processing and innovative structures, further amplify their application value:

High-precision planar processing: By adopting five-axis linkage numerical control technology, the flatness of the base is controlled within ±0.5μm/m, providing an ultra-flat reference surface for drilling equipment and ensuring that the verticality error of the drill bit is less than 0.01°.

Honeycomb shock absorption structure: The internal honeycomb design forms an independent cavity, achieving multi-level attenuation of vibration energy, and is particularly suitable for micro-hole processing of 0.1mm or less.

Pre-embedded water-cooling channels: For high-power drilling equipment, a built-in micro-channel water-cooling system is installed to control the temperature difference on the base surface within ±0.5℃, completely eliminating the risk of thermal deformation.

Customized T-slot layout: The T-slot spacing and precision (±0.01mm) are customized according to the drilling machine model to achieve rapid positioning and installation of the equipment, reducing the commissioning time of a single device by 70%.

Iii. Industry Evidence: Visible Efficiency Improvements

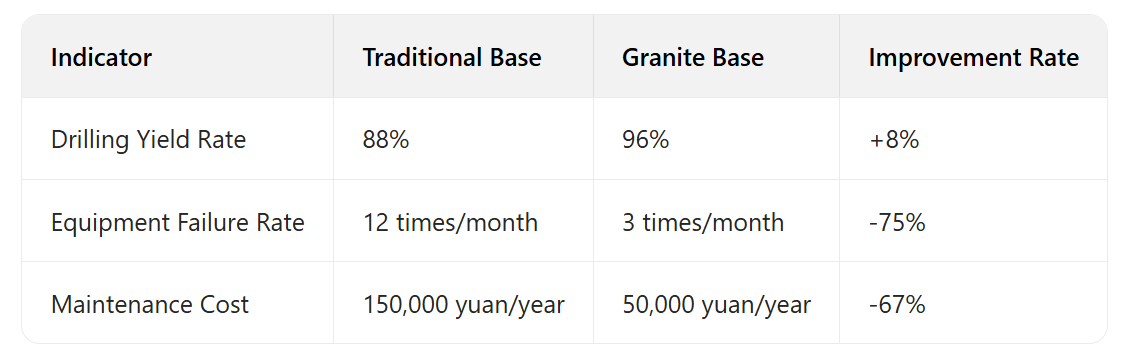

After a certain leading PCB manufacturer introduced granite bases, its production data achieved a breakthrough improvement:

More importantly, the granite base has helped enterprises break through technical bottlenecks, successfully undertake orders for micro-holes of 0.2mm or less, and open up high value-added markets.

Iv. Sustainable Advantages: An ideal choice for green manufacturing

Granite is a natural stone without chemical coatings and has zero VOCs emissions, meeting the RoHS environmental protection standards. Its extremely long service life reduces the frequency of equipment replacement, lowers resource consumption and carbon emissions. A certain environmental protection agency's calculation shows that using a granite base for a single PCB drilling device can reduce carbon emissions by 3 tons throughout its entire life cycle, which is in line with the green transformation trend of the manufacturing industry.

From micron-level precision control to full-process cost optimization, granite bases are reshaping the standards of PCB drilling processes with their irreplaceable performance advantages. In the current era of explosive demand for 5G and AI chips, choosing a granite base is not only an investment in product quality but also a crucial step to seize the technological high ground.

Post time: Jun-17-2025