In the fields of construction and industry, granite is widely used due to its hardness, density, acid and alkali resistance, and weather resistance. The following is a detailed analysis for you on whether the color of granite affects its density and how to choose more stable granite in the field of industrial precision equipment.

The relationship between the color and density of granite

Granite is mainly composed of minerals such as quartz, feldspar and mica, and its color depends on the types and quantities of the components it contains. From the perspective of density, there is a certain connection between color and density, but it is not a direct causal relationship.

Mineral composition differences: Light-colored granite, such as grayish-white and flesh-red, is often rich in quartz and feldspar. These two minerals have relatively high and stable densities. The density of quartz ranges from 2.6 to 2.7g/cm³, while that of feldspar varies from 2.5 to 2.8g/cm³ depending on the type. The abundance of such minerals leads to an upward trend in the overall density of light-colored granite. Dark granite, such as black and green, often contains a relatively high amount of iron and magnesium minerals as well as dark minerals like amphibole and biotite. The density of amphibole is approximately 3.0-3.4g /cm³, and that of biotite is about 2.7-3.1g /cm³. However, when dark granite contains more heavy metal elements (such as iron and manganese), its density will increase.

Degree of crystallization and structural influence: Color can sometimes reflect the differences in the degree of crystallization and structure of granite. Granite with a high degree of crystallization and dense structure has relatively uniform and stable color, and its density is also relatively high. This is because the mineral particles are closely arranged and have a large mass per unit volume. Granite with poor crystallization and loose structure may have mottled and uneven colors, many internal voids, and relatively low density.

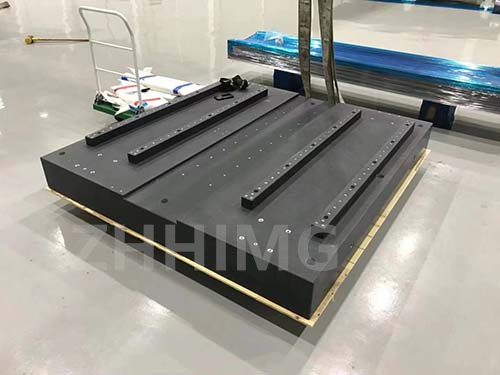

Granite selection in the field of industrial precision equipment

In the field of industrial precision equipment, the stability requirements for granite are extremely high. Usually, the appropriate granite is selected by comprehensively considering multiple factors:

Mineral composition and structure: Granite with a high content and uniform distribution of quartz and feldspar is preferred. This type of granite has a stable internal structure, which can effectively reduce deformation caused by changes in internal stress and ensure the long-term stable operation of the equipment. Meanwhile, granite with a high degree of crystallization, fine and uniform particles, and dense structure is the preferred choice. During long-term use and force application, it can better maintain accuracy and reduce the impact of its own structural changes on equipment accuracy.

Physical performance indicators: Granite is required to have a low water absorption rate, generally less than 0.5%, to prevent problems such as volume expansion and strength reduction caused by water absorption, which may affect the accuracy of the equipment. The coefficient of thermal expansion should be low. Ideally, it should be less than 8×10⁻⁶/℃ to reduce dimensional changes caused by temperature variations. In addition, the compressive strength should be high, generally greater than 150MPa, to ensure it can withstand various forces during the operation of the equipment.

Common varieties recommended: Jinan Green Granite, Indian Black, South African Black and other black granite, which are mostly dark in color, dense in structure, have a low coefficient of thermal expansion and good wear resistance, and are suitable for the bases of optical inspection equipment with extremely high requirements for precision and stability. Sesame white granite, with a light color, uniform mineral particles, and high hardness and strength, is widely used in electronic chip manufacturing equipment and can meet the requirements of high-precision positioning and long-term stable operation of the equipment.

In conclusion, although there is a certain correlation between the color and density of granite, when choosing granite in the field of industrial precision equipment, it is necessary to comprehensively consider multiple aspects such as mineral composition, structure, and physical properties to ensure the high precision and stability of the equipment.

Post time: May-19-2025