In the automotive industry, the dimensional accuracy of components directly affects the performance, safety and reliability of the entire vehicle. From key components of the engine to precision transmission parts, every minor dimensional deviation can trigger a chain reaction, leading to abnormal noises, increased fuel consumption and even safety hazards in the vehicle. Granite measuring tools, with their unique physical properties and technical advantages, have become the core tools to ensure the ultimate dimensional accuracy in the manufacturing process of automotive parts, laying a solid foundation for the high-quality development of the automotive industry.

The natural advantages of granite measuring tools: the foundation of stability and precision

Granite is a kind of natural stone formed through long-term geological processes. Its internal mineral crystals are dense and the structure is dense and uniform, which endows it with outstanding performance. Firstly, granite has an extremely low coefficient of thermal expansion, typically ranging from 5 to 7×10⁻⁶/℃. This characteristic makes it almost unaffected by temperature changes. In automotive parts manufacturing workshops, heat generated by equipment operation and fluctuations in environmental temperature are quite common. Measuring tools made of ordinary materials may cause dimensional errors due to thermal expansion and contraction, affecting measurement accuracy. Granite measuring tools can maintain dimensional stability when the temperature changes, ensuring the reliability of measurement data and providing precise reference standards for the processing of components.

Secondly, the high hardness and wear resistance of granite are another major advantage of it. Granite with a Mohs hardness of 6 to 7 is not prone to wear during frequent measurement operations. The manufacturing of automotive parts often involves a large amount of repetitive measurement work. Granite measuring tools can maintain high-precision measurement surfaces throughout long-term use, reduce measurement deviations caused by tool wear, extend service life and lower the tool replacement costs for enterprises at the same time. In addition, granite also has excellent vibration damping performance, which can effectively absorb the vibrations generated by the operation of machine tools and logistics transportation in the workshop, providing a stable environment for the measurement process, avoiding vibration interference with the measurement results, and ensuring the accuracy of dimensional inspection.

Key applications of granite measuring tools in the manufacturing of automotive parts

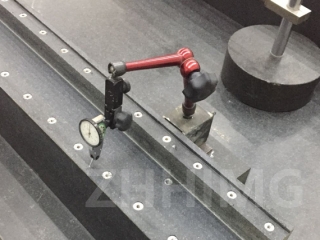

In the engine manufacturing process, granite measuring tools play a crucial role. The dimensional accuracy of core components such as the engine block and cylinder head directly affects the combustion efficiency and power output. The granite platform, with its extremely high flatness (up to ±0.005mm/m), provides an accurate reference for the flatness detection of the cylinder block and ensures the sealing of each joint surface. Granite gauge blocks, dial indicator stands and other tools can precisely measure key parameters such as the diameter of the piston pin hole and the size of the crankshaft journal, strictly controlling the error at the micrometer level to ensure the assembly accuracy and operational stability of the engine.

Granite measuring tools are also indispensable in the manufacturing of automotive transmission system components. The tooth profile accuracy of the transmission gears, the cylindricity of the shaft parts and other indicators are directly related to the smoothness of gear shifting and the transmission efficiency of the vehicle. The granite guide rail type measuring instrument can guide the measuring probe to precisely scan the gear tooth profile with extremely high straightness and stability, and the error detection accuracy can reach ±0.002mm. Granite square boxes are used to detect the perpendicularity and parallelism of shaft parts, ensuring the accuracy of the assembly relationship between each component and enhancing the reliability of the transmission system.

In addition, during the manufacturing process of automotive chassis components, the dimensional accuracy requirements for parts such as the suspension system and steering system are equally strict. Granite measuring tools precisely measure and control the dimensions such as the hole diameter, slot width, and length of components, ensuring the interchangeability and assembly accuracy of each part of the chassis, and providing a guarantee for the stability and handling of vehicle operation.

Promote the advancement of automotive manufacturing towards higher precision

As the automotive industry moves towards intelligence and electrification, the requirements for the precision of components are becoming increasingly strict. Granite measuring tools, with their stable performance and outstanding precision, have become a key weapon for automotive manufacturing enterprises to improve product quality and enhance market competitiveness. By using granite measuring tools, enterprises can strictly control the dimensions of components, reduce the scrap rate, shorten the production cycle and improve production efficiency.

In the future, with the continuous advancement of automotive manufacturing technology, granite measuring tools will also be deeply integrated with digital measurement technology and automated detection systems, further enhancing the intelligence level and accuracy of measurement. From traditional fuel vehicles to new energy vehicles, granite measuring tools will continue to safeguard the ultimate precision manufacturing of automotive parts, promoting the automotive industry to move towards higher-quality development.

Post time: May-08-2025