Granite mechanical components are widely used in modern industry due to the natural material’s exceptional hardness, compressive strength, and corrosion resistance. With precision machining techniques, granite becomes an ideal alternative to metal in a wide range of mechanical, chemical, and structural applications.

This article outlines the manufacturing process, key features, and typical application scenarios of granite components in industrial machinery.

Why Choose Granite for Mechanical Components?

Granite is a naturally occurring igneous rock composed primarily of:

-

Pyroxene

-

Plagioclase feldspar

-

Minor olivine and biotite mica

-

Trace magnetite

After natural aging, granite exhibits uniform texture, low porosity, and high structural integrity—making it ideal for precision industrial use.

Core Advantages of Granite Mechanical Parts

1. High Hardness and Wear Resistance

Granite has a Mohs hardness above 6, making it highly resistant to wear. It is ideal for high-load, high-speed parts such as machine tool bases, gears, and linear guides.

2. Excellent Corrosion Resistance

Unlike metal components, granite is naturally resistant to acids, alkalis, and salts. It is perfect for chemical processing equipment, marine machinery, and corrosive environments.

3. Strong Compressive Strength

Granite’s structure allows it to withstand high mechanical loads without deformation, making it ideal for pressure-bearing components such as vessels, support columns, and load frames.

4. Dimensional Stability

With a low thermal expansion coefficient, granite maintains its shape under extreme temperature changes. It’s commonly used in high-precision and high-temperature environments.

5. Aesthetic and Functional

Due to its rich colors and polished surface, granite is also used in architectural machinery, monuments, and sculptural mechanical parts, combining performance with visual appeal.

Granite Mechanical Component Manufacturing Process

1. Material Selection

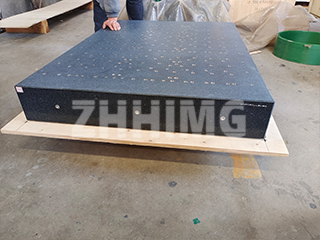

Only granite blocks with no cracks, uniform grain, and minimal internal stress are selected. Black granite is often preferred due to its superior thermal and structural properties.

2. Cutting

Granite is cut into rough blocks of the required size using diamond wire saws or blade cutters, depending on the part’s geometry.

3. Shaping and CNC Machining

Rough-cut blocks are machined into final shapes using CNC machines, grinders, or manual polishing, depending on tolerance requirements. Components like machine bases or gear housings require micron-level precision.

4. Surface Treatment

Surfaces are finely ground, honed, and polished to meet technical requirements. For mechanical parts, this ensures tight fitment and accurate alignment.

5. Final Inspection

Each component undergoes dimensional verification, surface inspection, and structural testing to ensure compliance with international standards and custom specifications.

Key Application Areas

1. Machine Tool Manufacturing

Granite is commonly used to produce CNC machine bases, coordinate measuring machine beds, and spindle mounts, thanks to its stability and vibration-damping performance.

2. Engineering Machinery

Granite gears, shafts, and other wear-resistant parts are ideal for heavy-duty construction and mining equipment.

3. Chemical Processing Equipment

Granite vessels, pumps, or pipeline supports offer high corrosion resistance in aggressive chemical environments.

4. Architectural and Decorative Components

Granite mechanical parts are also applied in high-end architectural installations, combining engineering function with aesthetic design, such as in custom columns, artistic machinery casings, or industrial-grade sculptures.

Conclusion

Granite mechanical components offer a powerful combination of durability, precision, and corrosion resistance, making them an excellent choice for industries demanding reliable performance under harsh conditions. With advancements in CNC granite machining and modular design, granite is becoming a viable and sustainable alternative to traditional metal-based mechanical systems.

Post time: Aug-01-2025