In the field of medical equipment manufacturing, precise positioning is the key to ensuring diagnostic accuracy and treatment safety. Granite precision parts, with their unique physical properties and outstanding performance, are becoming an indispensable and important component of medical equipment and are widely used in multiple key fields.

The application fields of granite precision accessories in medical equipment

Medical imaging equipment: In large-scale medical imaging equipment such as CT and MRI, granite precision parts are used to manufacture the base and support structure of the equipment. These devices have extremely high requirements for stability. Even the slightest vibration or displacement can cause blurred imaging and affect the diagnostic results. The high damping property and stable structure of granite can effectively isolate external vibration interference, ensuring that the equipment remains stable during operation and thus obtaining clear and accurate images.

Radiotherapy equipment: Radiotherapy equipment needs to precisely focus the radiation onto the tumor site while minimizing damage to the surrounding healthy tissues to the greatest extent. Granite precision accessories are used to make the treatment beds and positioning devices of radiotherapy equipment. Their high precision and stability can ensure that patients maintain a fixed and accurate position during the treatment process, allowing the rays to precisely irradiate the target area and improve the treatment effect.

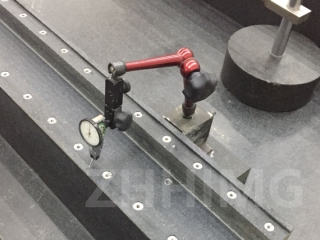

Surgical robots: Surgical robots have extremely high requirements for motion accuracy and stability. Granite precision guide rails and sliders and other accessories can provide smooth and precise movement for the mechanical arm of the surgical robot, ensuring that surgical instruments can precisely reach the designated position during operation, achieving refined operation in minimally invasive surgery and reducing surgical risks.

The principle by which granite achieves precise positioning of medical instruments

First of all, granite has an extremely low coefficient of thermal expansion, generally ranging from 5 to 7×10⁻⁶/℃. Medical equipment generates heat during long-term operation, and the ambient temperature may also change. Ordinary materials are prone to dimensional changes due to thermal expansion and contraction, which affects the positioning accuracy of the equipment. Granite is almost unaffected by temperature changes and can always maintain a stable size and shape, providing a stable foundation for the precise positioning of medical instruments.

Secondly, the internal structure of granite is dense and uniform, and it has good rigidity and wear resistance. During the frequent use of medical equipment, granite precision parts are not prone to wear and deformation and can maintain high-precision performance for a long time. Meanwhile, its outstanding vibration damping performance can effectively absorb external vibrations, reduce vibration interference during the operation of the equipment, ensure the stability of the instrument in various complex environments, and achieve precise positioning.

In addition, through advanced processing techniques, granite precision accessories can achieve extremely high manufacturing accuracy. High-precision surface flatness and dimensional tolerance control enable granite fittings to fit perfectly with other components of medical instruments, further enhancing the overall positioning accuracy of the equipment.

In conclusion, granite precision accessories, with their unique performance advantages, play a significant role in the field of medical equipment, providing reliable guarantees for the precise positioning of medical instruments and promoting the continuous advancement of medical technology to higher levels.

Post time: May-07-2025