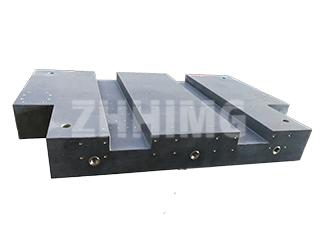

Proper Installation Techniques for Granite Precision Bearings

The installation process of granite precision bearings demands meticulous attention to detail, as even minor misalignments can compromise the component’s inherent precision properties. Before beginning any installation, I always recommend conducting a thorough pre-installation inspection to verify component integrity, connection accuracy, and the functionality of associated moving parts. This preliminary check should include examining the bearing raceways and rolling elements for signs of corrosion or damage, ensuring smooth movement without resistance—a step often overlooked but crucial for preventing premature wear.

When preparing to mount the bearings, start by cleaning all surfaces to remove protective coatings or residues. A lint-free cloth with isopropyl alcohol (70-75% concentration) works best for this task, as it evaporates completely without leaving residues that could affect fitting tolerances. During this cleaning process, pay special attention to the bearing interfaces; any particulate matter trapped between surfaces during installation can create uneven stress points that degrade precision over time.

The actual mounting process requires careful handling to avoid damaging the granite’s precision-ground surfaces.

For precision bearings, use lithium-thickened mineral grease (NLGI Grade 2) for standard conditions or SKF LGLT 2 synthetic grease for high-speed/high-temperature environments. Fill bearings to 25-35% of free space and perform low-speed run-in to distribute lubricant evenly.

Securing the bearings properly involves selecting appropriate anti-loosening devices based on operational requirements. Options include double nuts, spring washers, split pins, or lock washers with slotted nuts and tab washers, each offering distinct advantages in different applications. When tightening multiple bolts, always use a crisscross sequence, gradually increasing torque rather than fully tightening one fastener before moving to the next. This technique ensures uniform clamping force around the bearing housing. For long strip connections, begin tightening from the center and work outward in both directions to prevent warping or distortion of mating surfaces. A good rule of thumb is to leave thread ends protruding beyond nuts by 1-2 threads to ensure full engagement without bottoming out.

After mechanical installation, the critical process of aligning the granite components begins. Using an electronic level or precision spirit level, place the instrument on multiple points across the surface to check for evenness. If the bubble appears left of center, the left side is higher; if right, the right side requires adjustment. True horizontal alignment is achieved when the bubble remains centered across all measurement points—a step that directly impacts the accuracy of all subsequent machining or measurement operations.

The final phase of installation involves monitoring the startup sequence to ensure all parameters fall within acceptable ranges. Key metrics to observe include rotational speed, movement smoothness, spindle behavior, lubrication pressure and temperature, as well as vibration and noise levels. I always recommend maintaining a log of these initial readings for future reference, as they establish a baseline for normal operation. Only when all startup parameters stabilize within specified tolerances should you proceed to operational testing, which should include verification of feed rates, travel adjustments, lifting mechanism functionality, and spindle rotation precision—critical quality checks that validate the installation’s success.

Essential Maintenance Practices for Maximizing Granite Component Lifespan

While granite’s inherent properties provide excellent durability, its longevity in precision applications ultimately depends on implementing proper maintenance protocols that protect its structural integrity and precision characteristics. Having maintained calibration laboratories with granite surfaces for years, I’ve developed a maintenance routine that consistently extends component life beyond manufacturer projections—often by 30% or more—while preserving critical accuracy specifications.

Environmental control forms the foundation of effective granite component maintenance.

Maintain operating environment at 20±2°C with 45-55% humidity. Clean surfaces using 75% isopropyl alcohol and soft microfiber cloths; avoid acidic cleaners. Schedule annual calibration with laser interferometers (e.g., Renishaw) to verify flatness within ±0.005mm/m.

These precision tools should be installed in stable conditions. They prevent thermal cycles, moisture absorption, and particulate abrasion that degrade surface finish.

When controls are unavoidable, use insulated covers during non-operational periods. They buffer against temperature fluctuations in facilities with daily heating cycles.

Daily usage practices significantly impact long-term performance. Always place workpieces gently on granite surfaces to avoid impact damage.

Never slide rough materials across precision-ground surfaces. This prevents micro-scratches that compromise measurement accuracy over time.

Equally important is respecting load limits. Exceeding rated capacity risks immediate damage and gradual deformation affecting precision.

I keep a laminated load capacity chart near each workstation as a constant reminder for all operators.

Regular cleaning is essential for preserving granite’s precision properties. After each use, remove all debris and wipe the surface with a soft cloth.

Microfiber works best for trapping fine particles without scratching. For thorough cleaning, use neutral pH detergent formulated for stone surfaces.

Avoid harsh chemicals or abrasive cleaners that can etch or dull the finish. My team uses 75% isopropyl alcohol to remove oils without damaging components.

When not in use for extended periods, proper storage becomes critical. Thoroughly clean all surfaces before storage.

Apply a thin coat of rust inhibitor to metal components. Cover the entire assembly with a breathable, dust-resistant cover.

I recommend using original packaging for long-term storage. It supports components without creating pressure points that could cause warping.

For seasonal operations, this storage protocol prevents condensation and temperature-related stresses during idle periods.

An often-overlooked aspect is re-leveling after any movement. Even minor repositioning can disrupt precision tools.

Recalibrate horizontal alignment using electronic or spirit level techniques from initial installation. Many precision issues trace back to unlevel components after movement.

Establish a regular inspection schedule to identify potential issues before they affect performance. Weekly checks should include surface condition assessments.

Quarterly inspections might involve detailed measurements of flatness and parallelism using precision instruments. Documenting these creates a maintenance history.

This helps predict when preventative maintenance is needed, allowing scheduled downtime rather than unexpected failures. Facilities with proactive industrial stone maintenance achieve longer service lives and more reliable performance from their equipment.

Granite’s exceptional dimensional stability and wear resistance make it invaluable for precision machinery components. These benefits are fully realized through proper installation and maintenance practices.

As we’ve explored, careful attention to alignment, cleaning, and environmental control during installation establishes the foundation for long-term performance. Consistent maintenance preserves accuracy and extends service life.

For manufacturing professionals working with these specialized components, mastering these techniques reduces downtime and lower replacement costs. They ensure consistently reliable precision measurements.

Remember that granite precision measurement tools represent a significant investment in manufacturing quality. Protecting that investment through proper care ensures equipment delivers precision results for years to come.

Post time: Nov-19-2025