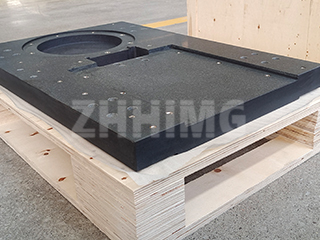

ZHHIMG® granite precision platforms are primarily made from high-density black granite (~3100 kg/m³). This proprietary material ensures long-term stability and superior performance in ultra-precision industries. The granite’s composition includes:

-

Feldspar (35–65%): Enhances hardness and structural stability

-

Quartz (20–50%): Improves wear resistance and thermal stability

-

Mica (5–10%): Adds structural toughness

-

Minor black minerals: Increase overall density and rigidity

Why Use High-Density Black Granite?

-

High Hardness – Resists wear and scratches, ensuring long-term precision.

-

Excellent Thermal Stability – Low thermal expansion (~4–5×10⁻⁶ /°C) minimizes measurement errors due to temperature changes.

-

High Density & Low Vibration – Dense structure reduces vibration, ideal for CMMs, laser systems, and precision CNC equipment.

-

Chemical Resistance & Durability – Resistant to oils, acids, and other industrial chemicals, offering long service life.

-

Nanometer-Level Precision – Can be ground manually or with advanced machines to achieve micro- or nano-level flatness, essential for high-precision inspection and assembly.

Conclusion

High-density black granite is the preferred material for ZHHIMG® granite precision platforms because it combines stability, hardness, low thermal expansion, vibration resistance, and durability. These properties ensure that our platforms maintain consistent, ultra-precise measurements, supporting the demanding needs of ultra-precision industries worldwide.

Post time: Sep-23-2025