In modern precision manufacturing, accuracy is not a feature—it is a prerequisite. From machine tool alignment to high-end quality inspection, precision measuring tools form the foundation of dimensional control. Among these tools, squares and surface plates play a critical role in ensuring perpendicularity, flatness, and geometric accuracy. As global industries continue to move toward ultra-precision, the comparison between granite squares and traditional steel squares has become a frequent topic of interest among engineers, quality managers, and procurement specialists.

At the same time, search interest in granite surface plates and advanced metrology solutions continues to rise across Europe and North America. This article examines the technical differences between granite squares and steel squares, analyzes market trends related to granite surface plates, and provides an overview of key types of precision measuring tools—while highlighting how ZHHIMG supports global customers with high-performance granite metrology solutions.

Granite Square vs. Steel Square: Material-Level Comparison

Precision squares are widely used to verify squareness in machine assemblies, guideway installation, and inspection environments. While steel squares have a long history in industrial measurement, granite squares are increasingly preferred in high-precision applications.

Dimensional Stability

Steel squares are susceptible to thermal expansion and residual stress from machining and heat treatment. Even minor temperature variations can introduce measurable deviation in high-accuracy environments. Granite squares, by contrast, offer exceptional thermal stability. Natural black granite exhibits a low coefficient of thermal expansion and excellent internal stress balance, allowing it to maintain geometry even under fluctuating ambient conditions.

Wear Resistance and Long-Term Accuracy

Repeated contact with metal parts causes gradual wear on steel squares, particularly along reference edges. This wear directly impacts measurement reliability and requires frequent recalibration or replacement. Granite squares feature high surface hardness and natural wear resistance. When properly maintained, they retain accuracy for decades, making them well-suited for long-term use in metrology labs and production inspection areas.

Corrosion and Environmental Resistance

Steel squares require protective coatings or controlled environments to prevent corrosion, especially in humid conditions. Granite squares are naturally corrosion-resistant and non-magnetic, making them ideal for cleanrooms, optical inspection rooms, and semiconductor manufacturing environments.

Calibration and Traceability

Both granite and steel squares can be calibrated to international standards. However, granite squares typically exhibit better long-term calibration stability, reducing recalibration frequency and total cost of ownership over the equipment lifecycle.

Rising Search Interest in Granite Surface Plates

In recent years, granite surface plates have shown steadily increasing search interest in the European and North American markets. This trend reflects broader changes in manufacturing technology and quality requirements.

Drivers Behind Market Growth

Several factors contribute to the growing demand for granite surface plates:

- Expansion of semiconductor, optics, and laser equipment manufacturing

- Higher accuracy requirements in CNC machining and coordinate measuring machines

- Increased adoption of automation and inline inspection systems

- Preference for vibration-damping and thermally stable materials

Granite surface plates provide a flat, stable datum for precision measurement and assembly. Compared to cast iron alternatives, granite offers superior vibration damping, improved thermal behavior, and lower maintenance requirements.

Application Expansion

Beyond traditional inspection rooms, granite surface plates are now widely used as structural bases for precision machines, air-bearing stages, and optical platforms. This expanded role has further increased online search activity related to custom granite plates, high-precision granite bases, and granite metrology components.

Types of Precision Measuring Tools in Modern Manufacturing

Precision measurement relies on a complete ecosystem of tools, each serving a specific function within quality control and process validation.

Surface Plates

Granite surface plates form the reference foundation for dimensional inspection. They are used with height gauges, indicators, and CMM fixtures to establish accurate measurement baselines.

Precision Squares and Straightedges

Granite and steel squares verify perpendicularity, while straightedges are used to assess straightness and flatness of machine components, guideways, and assembly surfaces.

Coordinate Measuring Machines (CMMs)

CMMs provide high-accuracy three-dimensional measurement for complex parts. Granite is widely used as the base material for CMM structures due to its stability and vibration damping properties.

Optical and Laser Measuring Systems

Advanced optical comparators and laser interferometers support non-contact measurement at micron and sub-micron levels. These systems often rely on granite bases to ensure measurement integrity.

Specialized Metrology Fixtures

Custom granite fixtures, angle plates, and machine bases are increasingly used to support industry-specific inspection and assembly processes, particularly in aerospace, electronics, and semiconductor sectors.

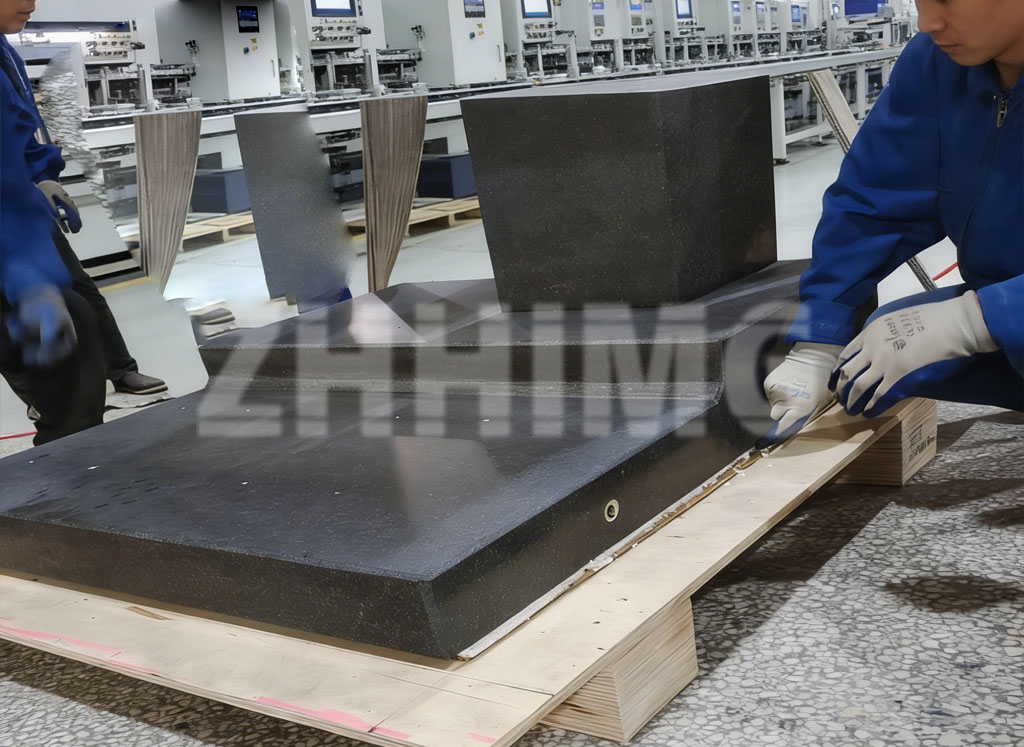

ZHHIMG’s Role in Precision Granite Metrology

ZHHIMG specializes in the design and manufacturing of high-precision granite components for global industrial customers. Leveraging premium black granite and advanced precision grinding techniques, ZHHIMG delivers granite surface plates, squares, machine bases, and custom metrology structures that meet stringent international standards.

With extensive experience serving customers in Europe and North America, ZHHIMG supports applications ranging from quality inspection and machine calibration to ultra-precision equipment manufacturing. Each granite component is produced under controlled conditions and inspected using high-accuracy measurement systems to ensure consistency, reliability, and long-term performance.

Conclusion

As precision requirements continue to tighten across global manufacturing industries, the choice of measurement tools and materials has become increasingly critical. Compared to traditional steel squares, granite squares offer superior stability, durability, and environmental resistance, making them a preferred solution for high-accuracy applications. At the same time, rising search interest in granite surface plates reflects the broader shift toward stable, low-maintenance metrology foundations.

Through continuous investment in material quality and precision manufacturing, ZHHIMG remains committed to supporting customers with reliable granite metrology solutions that meet the evolving demands of modern industry.

Post time: Jan-21-2026