Applications of Granite Straightedges

Granite straightedges are essential tools in industrial inspection, precision measurement, layout marking, equipment installation, and construction engineering. They provide a reliable and stable reference for a wide range of precision applications.

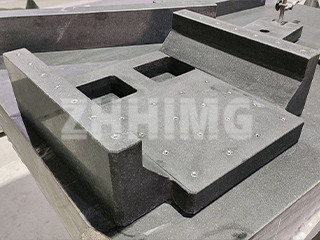

Material Composition

Our granite straightedges are crafted from carefully selected natural stone, processed through precision machining and fine hand polishing. The result is a dark-colored, fine-grained, uniform stone with excellent stability, strength, and hardness. Granite straightedges maintain high accuracy under heavy loads and normal temperature conditions, and feature:

-

Rust-free surface

-

Acid and alkali resistance

-

High wear resistance

-

Non-magnetic and dimensional stability

Key Features of Granite Straightedges

-

Superior Physical Properties – Natural granite undergoes long-term aging, resulting in a fine, uniform structure with minimal thermal expansion and no internal stress, ensuring it does not deform.

-

High Rigidity and Hardness – The granite surface is extremely durable and resistant to wear, maintaining long-term precision.

-

Temperature Stability – Granite straightedges remain accurate under varying environmental temperatures without affecting flatness or surface appearance.

-

Smooth Measurement – The straightedge surface does not develop scratches or magnetic effects, allowing smooth and effortless movement during inspections.

-

Corrosion Resistance & Low Maintenance – Resistant to acid and alkali solutions, rust-free, and easy to clean, offering a long service life.

-

Ergonomic Design – Each straightedge features weight-reducing holes for easier handling and operation.

Advantages of Granite Straightedges

Granite straightedges, made from natural stone and finely processed, combine high stability, durability, and precision. Their key benefits include:

-

High hardness and strength – Ensuring precise measurements even under heavy loads

-

Corrosion and rust resistance – Safe for long-term use in industrial environments

-

Non-magnetic and dimensionally stable – Ideal for sensitive precision inspections

-

Wear-resistant surface – Maintains accuracy over prolonged usage

As a reference measuring tool, granite straightedges provide an ideal flat surface for inspecting instruments, machinery components, and other precision parts, ensuring reliable results every time.

Post time: Aug-14-2025