Precision metrology systems form the backbone of modern manufacturing quality control. As tolerances tighten and component complexity increases, the accuracy and stability of measurement equipment have become critical competitive factors for manufacturers worldwide. At the heart of many of these systems are granite surface plates and granite-based structures, which provide stable reference geometries for dimensional inspection and coordinate measurement.

In Europe and North America, demand for high-performance granite surface plate manufacturers has grown steadily alongside the expansion of semiconductor manufacturing, aerospace production, and advanced automation. This article examines the role of granite surface plate manufacturers within the precision metrology ecosystem, explores key applications of granite in coordinate measuring machines (CMMs), and outlines how granite supports the performance of modern precision metrology systems.

Granite Surface Plate Manufacturers: Market Expectations and Technical Requirements

Granite surface plates are foundational elements in dimensional metrology. They provide flat, stable reference planes for inspection, calibration, and assembly tasks. However, not all granite surface plate manufacturers deliver the same level of performance or consistency.

High-quality manufacturers focus on material selection as a primary differentiator. Premium black granite with uniform grain structure and high density offers superior dimensional stability and wear resistance. Inferior materials may meet initial flatness requirements but can exhibit long-term drift or localized wear under continuous use.

Manufacturing capability is equally critical. Precision grinding and lapping must be performed in temperature-controlled environments to achieve micron-level flatness and straightness. Reputable granite surface plate manufacturers also maintain robust inspection systems, including laser interferometry and calibrated reference instruments, to verify compliance with international standards.

For customers in Europe and North America, traceability, documentation, and consistent quality are essential. Surface plates are often integrated into certified quality systems, making long-term accuracy and recalibration stability key evaluation criteria when selecting a supplier.

Applications of Granite in Coordinate Measuring Machines (CMMs)

Coordinate measuring machines represent one of the most demanding applications for precision granite components. In CMMs, granite is not limited to surface plates alone, but is widely used as a structural material throughout the machine.

Granite as the CMM Base Structure

The base of a CMM must provide exceptional stiffness and thermal stability to support accurate three-dimensional measurement. Granite bases offer low thermal expansion and excellent vibration damping, minimizing measurement uncertainty caused by environmental changes or external disturbances.

Unlike welded or cast metal structures, granite bases are free from residual stress, allowing them to maintain geometric integrity over long service life. This makes granite an ideal material for both bridge-type and gantry-type CMM designs.

Granite Bridges and Columns

Granite is also used for bridges, columns, and guideway structures within CMMs. These components must maintain precise alignment under dynamic motion while supporting moving masses such as probing systems and carriages. The inherent damping characteristics of granite improve system stability and reduce settling time during measurement cycles.

Integration with Air Bearings and Linear Drives

Many high-end CMMs use air bearings and linear motors to achieve smooth, low-friction motion. Granite surfaces provide excellent reference planes for air bearing systems, supporting consistent air film behavior and repeatable positioning accuracy. This integration further enhances the overall performance of precision metrology systems.

Granite in Modern Precision Metrology Systems

Beyond traditional CMMs, granite plays a central role in a wide range of precision metrology systems. Optical measurement platforms, laser interferometer setups, and form measurement machines all rely on stable structural foundations to achieve reliable results.

Granite surface plates are frequently used as base platforms for optical comparators, vision measurement systems, and hybrid metrology equipment. Their vibration damping properties help isolate sensitive measurement processes from ambient disturbances in production environments.

In automated inspection lines, granite-based structures support inline measurement stations that operate continuously. The long-term stability of granite reduces the need for frequent recalibration, improving uptime and reducing total cost of ownership.

Industry Trends Driving Demand for Granite-Based Metrology Solutions

Several industry trends are contributing to increased demand for granite surface plates and granite-based metrology components. Semiconductor manufacturing continues to push measurement requirements into sub-micron and nanometer ranges, increasing reliance on ultra-stable machine structures.

At the same time, aerospace and automotive industries are adopting more complex geometries and tighter tolerances, requiring advanced inspection capabilities. Precision metrology systems built on granite foundations provide the stability needed to meet these challenges.

Automation and digital manufacturing further amplify this demand. As measurement systems become integrated directly into production lines, structural stability and environmental robustness become essential design considerations.

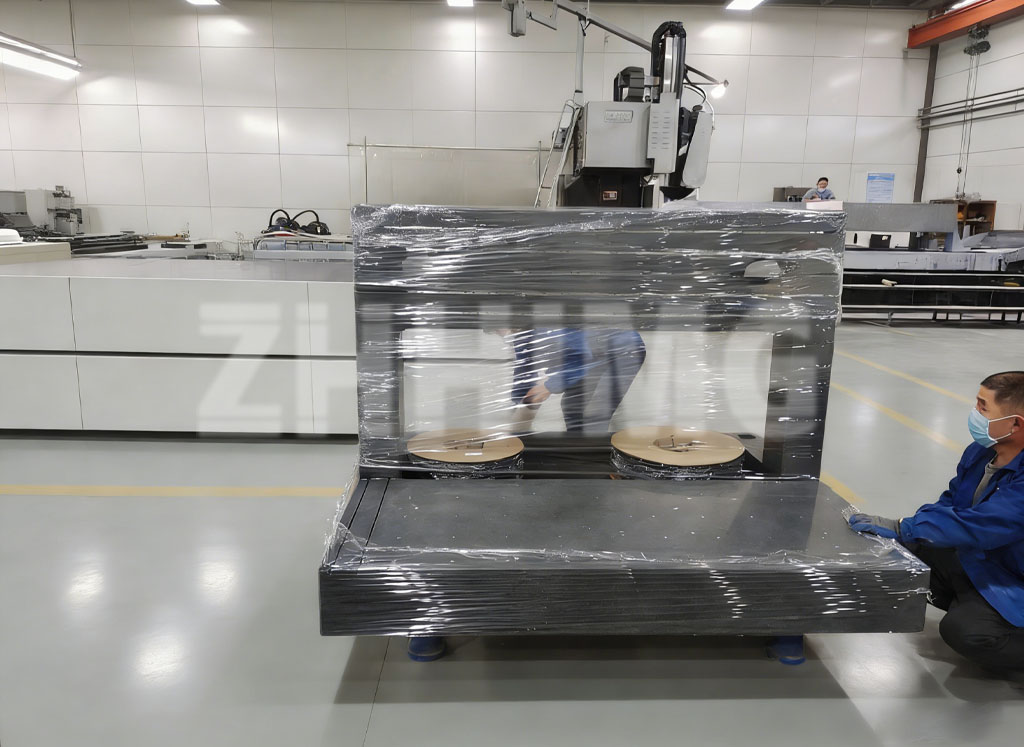

ZHHIMG’s Capabilities as a Precision Granite Manufacturer

ZHHIMG is an experienced manufacturer of precision granite components serving global customers in metrology and advanced manufacturing. By combining premium granite materials with advanced precision grinding and inspection technologies, ZHHIMG delivers granite surface plates and CMM structures that meet stringent international accuracy standards.

The company’s capabilities include standard and custom granite surface plates, granite bases for CMMs, bridge and gantry structures, and application-specific granite solutions for precision metrology systems. Each component is produced under controlled conditions and verified through comprehensive quality inspection.

Through close collaboration with equipment manufacturers and metrology professionals, ZHHIMG supports reliable system integration and long-term performance across a wide range of precision measurement applications.

Conclusion

Granite surface plates and granite-based structures remain indispensable components within modern precision metrology systems. From foundational reference planes to complete CMM structures, granite provides the stability, damping, and durability required to support accurate dimensional measurement.

As industries continue to advance toward higher precision and greater automation, the role of capable granite surface plate manufacturers will become increasingly important. With dedicated expertise in precision granite manufacturing, ZHHIMG is well positioned to support the evolving needs of global metrology and inspection markets.

Post time: Jan-21-2026