When manufacturing miniature parts, such as the leads of semiconductor chips and the fine catheters of minimally invasive surgical instruments, the precision requirements often reach the micrometer level - equivalent to one percent of the diameter of a human hair. At this point, a seemingly ordinary granite V-shaped block can become the key to precise processing. Today, let's uncover how this "stone tool" enables the processing of small parts to achieve astonishing precision.

Why choose granite for V-shaped blocks?

The V-block is a tool used to fix cylindrical parts and is shaped like a capital "V". The remarkable aspect of granite V-shaped blocks lies in:

The structure as stable as Mount Tai: The granite has an extremely high density (the black granite of ZHHIMG® reaches 3100kg/m³), and the internal mineral crystals are closely interlocked, just like a "V" shape cast from reinforced concrete, and will not deform even under heavy pressure.

Not afraid of temperature disruption: Ordinary metals expand when heated, but the coefficient of thermal expansion of granite is extremely low. Even if the temperature rises by 10℃ during processing, its deformation is so small that it can be ignored and will not cause the part to "deviate".

The more it is used, the more wear-resistant it becomes: The hardness of granite reaches 6-7 on the Mohs scale, which is even harder than steel. After long-term use, the surface remains smooth and flat, and will not produce errors due to wear like metal V-shaped blocks.

The magical steps for processing small parts with granite V-shaped blocks

Find a "stable seat" for the part

First, clean the V-shaped block thoroughly: Use anhydrous ethanol to wipe off the dust and oil stains on the surface. These micron-sized impurities (20 times thinner than a human hair) can cause the parts to tilt.

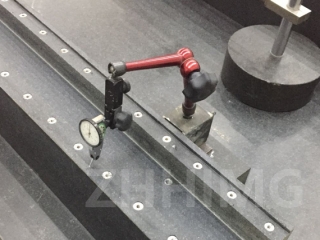

Fix the V-shaped block on the granite platform: Just like fixing a chair on a flat floor to ensure it won't shake during processing. The granite platform of ZHHIMG® has an extremely high flatness. Within a 1-meter length, the height difference does not exceed one-thousandth of the thickness of half a human hair.

2. Make the parts "sit upright"

Place small parts into V-shaped grooves: For example, when processing a 3mm diameter metal shaft, gently place it into a 90° V-shaped groove.

Calibrate with a dial indicator: This is a precise tool capable of measuring an error of 0.001mm. It's like "measuring the height" of a part to ensure it is completely level. If the shape of the part is special, granite parallel blocks (with a thickness error not exceeding 1μm) can also be used to raise it, keeping the machined surface level.

3. Hold it gently and don't "pinch" the part

Fix the parts with a fixture with a rubber head: The force should be controlled at 2 to 3 kilograms, just like gently holding an egg with your hand. It will neither slip nor break. The silent fixture of ZHHIMG® can also reduce vibration during processing, ensuring that the parts are stable and secure.

4. Start processing: Like giving a "haircut" to a part

Take the processing of semiconductor leads as an example: Use a femtosecond laser to cut the shape of a 0.1mm thick copper alloy lead. Granite V-shaped blocks can absorb over 90% of the vibration, making the verticality error of the laser cut less than 5μm - equivalent to an inclination of no more than one-tenth of a human hair at a height of 1 millimeter.

Post-processing inspection: Measured with a high-precision dial indicator, the ZHHIMG® V-shaped block is positioned to process a 5mm diameter shaft, with a thickness error controlled within 2μm, which is 30 times thinner than a human hair!

"Micro-precision" applications in daily life

The secret of 5G chips: The lead frame used for chip packaging needs to be cut into complex shapes on a 0.1mm thick copper sheet. Granite V-shaped blocks can make the cut as neat as a blade, ensuring stable signal transmission of the chip.

The "eyes" of minimally invasive surgery: When processing a stainless steel catheter with a diameter of 0.5mm, the granite V-shaped block can prevent the part from slipping, making the inner wall of the catheter as smooth as a mirror, allowing doctors to operate more precisely.

Iv. How to Maintain This "Precision Assistant"

Regular bathing: For every 50 parts processed, use ultrasonic waves to "bathe" the V-shaped block, washing away the metal debris and cutting fluid in the crevices.

Annual physical examination: Measuring the size of V-shaped blocks with laser instruments. The precision change of ZHHIMG® granite V-shaped blocks after one year of use is less than 1μm, which is even slower than the growth rate of human hair!

The next time you see a small and precise part, don't forget that there might be a granite V-shaped block silently "exerting force" behind it - with its hard texture formed over hundreds of millions of years, it supports the microscopic world of modern technology.

Post time: Jun-18-2025