In modern precision manufacturing, the choice of machine base is pivotal to achieving high accuracy, stability, and long-term reliability. Industries ranging from semiconductor fabrication to high-precision optics increasingly rely on bases that provide consistent structural performance. Among the most discussed materials in this context are granite and cast iron. Each has distinct physical properties, advantages, and limitations that influence system design, maintenance, and lifecycle cost.

This article explores the differences between granite machine bases and cast iron machine bases, highlights leading granite machine base manufacturers, and examines precision machine base considerations in contemporary industrial applications. The discussion reflects trends in Europe and North America and aligns with search behavior from engineering and procurement professionals seeking reliable technical guidance.

The Role of Precision Machine Bases

A precision machine base is more than just a support structure—it defines the reference geometry for motion systems, measuring instruments, and cutting or assembly operations. The stability, thermal behavior, and vibration damping characteristics of the base directly influence system performance and measurement repeatability.

Key Functions

- Structural Support: Provides rigidity for mounted components and ensures dimensional stability under load.

- Vibration Damping: Reduces the transmission of environmental or operational vibrations to sensitive components.

- Thermal Stability: Minimizes expansion or contraction with temperature changes to maintain alignment and calibration.

- Longevity: Ensures consistent performance over long service periods with minimal maintenance.

Understanding these functions helps engineers evaluate material options and optimize machine design.

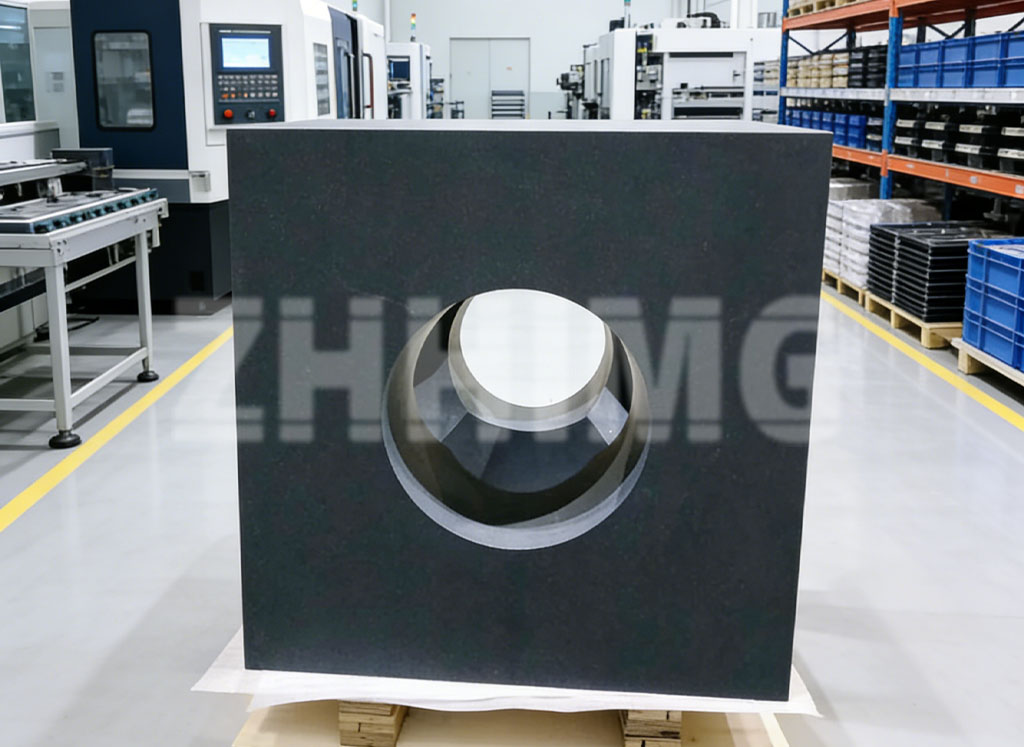

Granite Machine Bases: Properties and Advantages

Granite has long been a preferred material for high-precision bases, particularly in coordinate measuring machines (CMMs), laser systems, and optical inspection platforms.

Physical Properties

- Low Thermal Expansion: Granite exhibits minimal dimensional change with temperature fluctuations, contributing to stable alignment.

- High Mass Density: Its inherent mass dampens vibrations effectively.

- Isotropic Behavior: Uniform physical properties in all directions reduce warping or bending under load.

- Corrosion Resistance: Unlike metal, granite does not oxidize or degrade, requiring little to no protective treatment.

Advantages in Precision Applications

- Vibration Damping: Granite naturally absorbs high-frequency vibrations, improving measurement and process repeatability.

- Long-Term Stability: Maintains flatness and straightness over decades with minimal maintenance.

- Dimensional Accuracy: Ideal for applications requiring tight tolerances in microns.

Leading Manufacturers

Granite machine base manufacturers specialize in high-precision lapping, surface finishing, and quality control processes to deliver flat, stable platforms. Leading global suppliers include companies with ISO 9001, ISO 14001, and CE certifications that ensure consistent material selection, machining, and inspection standards.

Cast Iron Machine Bases: Properties and Applications

Cast iron has historically been the backbone of traditional machine tool construction and remains common in applications requiring high stiffness and load capacity.

Physical Properties

- Higher Coefficient of Thermal Expansion: More sensitive to temperature changes compared to granite.

- Moderate Damping: Graphite inclusions in gray cast iron provide some vibration absorption, but less than granite.

- High Stiffness: Excellent resistance to bending and deformation under heavy loads.

Advantages and Use Cases

- Heavy-Duty Applications: Well-suited for machine tools, CNC milling machines, and large industrial systems.

- Cost-Effectiveness: Generally lower material costs compared to high-grade granite.

- Machinability: Can be readily machined into complex geometries and integrated with mechanical features.

Limitations

- Thermal Sensitivity: Requires environmental control or active compensation in high-precision tasks.

- Maintenance Needs: Susceptible to corrosion; may require periodic reconditioning to maintain accuracy.

Comparative Analysis: Granite vs Cast Iron

| Feature | Granite | Cast Iron |

|---|---|---|

| Thermal Expansion | Low; excellent stability | Higher; sensitive to temperature changes |

| Vibration Damping | Excellent | Moderate |

| Load Capacity | Moderate; depends on geometry | High; supports heavy machinery |

| Maintenance | Minimal | Requires protection and periodic maintenance |

| Lifespan | Decades with consistent performance | Long, but may degrade under corrosion or thermal stress |

| Typical Applications | CMM, laser systems, optical benches | CNC machines, large industrial tools |

Implications for Designers

Granite is favored where vibration damping, thermal stability, and ultra-precision are priorities. Cast iron remains suitable for heavy-duty operations where stiffness and load-bearing capacity are more critical than absolute micrometer-level stability.

Selecting the Right Precision Machine Base

Engineers must evaluate several factors when selecting between granite and cast iron bases:

- Application Requirements: Determine the required precision, load, and environmental conditions.

- Budget Considerations: Balance material cost with performance benefits and lifecycle maintenance.

- System Integration: Consider compatibility with motion stages, sensors, and auxiliary equipment.

- Supplier Expertise: Collaborate with experienced manufacturers to ensure quality and compliance with precision standards.

Case Studies and Industry Examples

Coordinate Measuring Machines (CMMs)

Granite bases are standard in high-precision CMMs due to their stability and resistance to wear. Cast iron bases may be used in larger, less critical systems where high loads are anticipated.

Laser Cutting and Metrology Systems

Granite bases provide vibration damping essential for laser processing, improving cut quality and reducing error in micro-scale applications.

Machine Tools

Cast iron remains a dominant choice for milling and machining platforms where heavy workpieces and high cutting forces require substantial stiffness and structural integrity.

Conclusion

Both granite and cast iron machine bases play critical roles in precision manufacturing. Granite excels in applications requiring ultra-stability, vibration damping, and thermal consistency, making it ideal for CMMs, laser systems, and optical metrology. Cast iron is better suited for heavy-duty machine tools where stiffness and load capacity dominate.

Collaborating with experienced granite machine base manufacturers ensures that precision requirements are met while minimizing long-term maintenance. By carefully evaluating application needs, environmental conditions, and material properties, engineers can select the most appropriate base to maximize performance and reliability in precision equipment.

Post time: Jan-23-2026