In precision measurement, the accuracy of surface plates is paramount for ensuring that components meet required specifications. Surface plates are used to check the flatness and alignment of parts, which is crucial in manufacturing, aerospace, and metrology. However, choosing the right material for your surface plate is a decision that can impact your measurement results. The two most commonly used materials for surface plates are granite and cast iron. This article compares these materials, explains the importance of surface plate flatness grades, and offers insights into selecting the right tools for your precision measurement needs.

Granite Surface Plates: High Precision and Stability

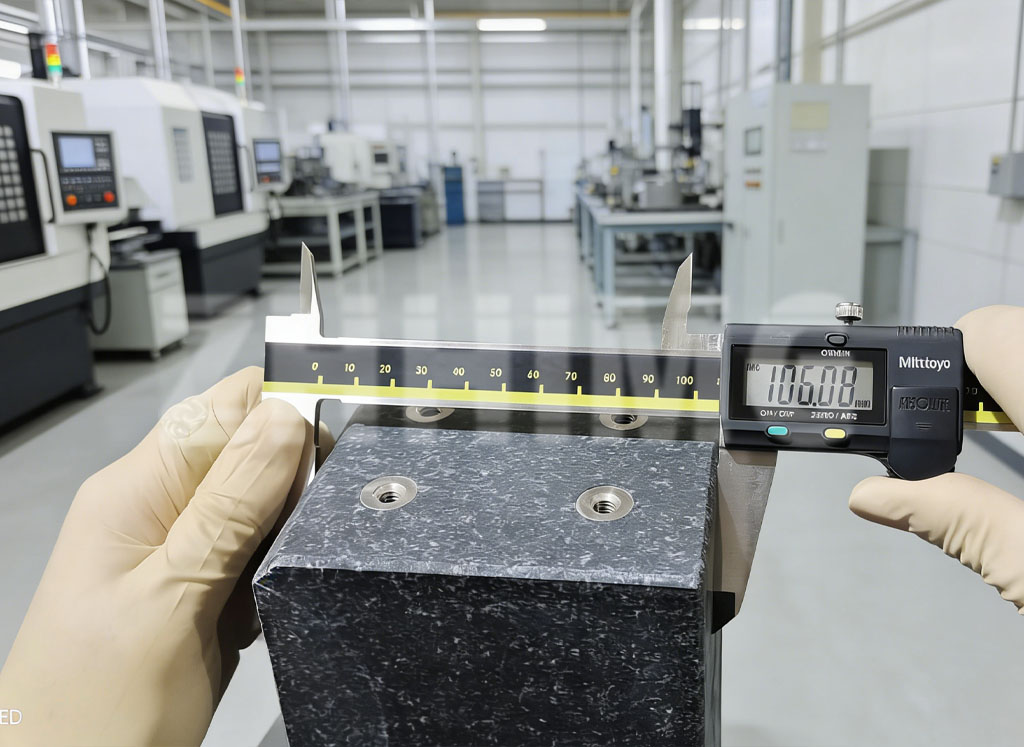

Granite is one of the most popular materials for precision surface plates due to its excellent properties. It is highly rigid, stable, and resistant to wear, making it ideal for environments where high accuracy is essential. Granite surface plates maintain their precision over time, even when exposed to temperature fluctuations, moisture, and other environmental factors. This stability makes granite an excellent choice for industries like aerospace and semiconductor manufacturing, where even the smallest deviation from flatness can lead to significant issues.

Granite is also highly durable, and with proper care, granite surface plates can last for many years without significant wear. As a material, granite has a very low thermal expansion coefficient, ensuring that its accuracy remains consistent across a wide range of temperatures. For applications requiring ultra-high precision, granite surface plates are often the material of choice.

Cast Iron Surface Plates: Durability and Cost-Effectiveness

While granite surface plates offer high precision, cast iron surface plates are often used in applications where durability and cost-effectiveness are key considerations. Cast iron has a high level of strength and can absorb vibrations effectively, making it suitable for general manufacturing processes. Cast iron surface plates are commonly found in industries where cost constraints are important but accuracy still plays a significant role.

Despite its benefits, cast iron is more prone to corrosion and wear compared to granite, which requires more maintenance to ensure longevity. Cast iron surface plates are also generally heavier than granite plates, which may make them less convenient to handle in certain applications.

Surface Plate Flatness Grades: What You Need to Know

Surface plate flatness grades are an essential factor in determining the level of precision a surface plate can provide. These grades define the allowable deviation from a perfectly flat surface, and choosing the right grade is critical for achieving accurate measurements.

-

Grade A: The most precise flatness grade, with the smallest allowable deviation from flatness. This grade is typically used for high-precision measurements in industries like aerospace, optics, and semiconductor manufacturing.

-

Grade B: Suitable for general manufacturing and machine tool calibration, where high precision is still important but not as critical as in Grade A applications.

-

Grade C: Commonly used for general industrial applications where strict tolerances are not required, such as in the construction and automotive industries.

Understanding the different flatness grades helps you select the right surface plate for your needs. Higher-grade surface plates are ideal for more demanding industries, while lower-grade plates can still be effective for less precise measurements.

How Surface Plate Material and Flatness Grade Affect Precision

The material of the surface plate, along with its flatness grade, determines its effectiveness in achieving high-accuracy measurements. A granite surface plate with a Grade A flatness tolerance will offer superior precision compared to a cast iron plate with a Grade C tolerance. When selecting a surface plate, it’s essential to consider both the material and flatness grade in relation to your specific measurement requirements.

Industry Applications: Choosing the Right Surface Plate

In industries like aerospace, automotive, and semiconductor manufacturing, precision measurement tools such as surface plates are essential for maintaining high standards of quality. In these sectors, selecting the appropriate surface plate material and flatness grade ensures that components meet strict tolerances.

For aerospace and semiconductor applications, a granite surface plate with a Grade A flatness tolerance is ideal. In contrast, for less demanding applications in general manufacturing, a cast iron surface plate with a Grade B or C flatness tolerance may be sufficient.

Conclusion

In conclusion, both granite and cast iron surface plates offer unique benefits depending on the precision requirements of your application. Granite provides unmatched stability and high precision, while cast iron offers durability and cost-effectiveness. Understanding surface plate flatness grades is essential for ensuring that your measurements meet the desired level of accuracy. At ZHHIMG, we offer precision surface plates made from the highest-quality materials, ensuring that you can achieve the utmost accuracy in your manufacturing processes.

Post time: Feb-09-2026