In the field of precision measurement, the three-coordinate measuring machine is the core equipment for controlling product quality, and the base serves as the foundation for its stable operation. Its thermal deformation performance directly determines the measurement accuracy. Granite and cast iron, as two mainstream base materials, have long attracted much attention for their differences in thermal deformation. With the visualization detection technology of thermal imagers, we can directly reveal the essential difference in thermal stability between the two, providing a scientific basis for equipment selection in the precision manufacturing industry.

Thermal deformation: The "Invisible Killer" Affecting the Accuracy of Three-coordinate Measurement

The three-coordinate measuring machine acquires three-dimensional data through the contact of the probe with the object being measured. Any thermal deformation of the base will cause the measurement reference to shift. In an industrial environment, factors such as heat generation during equipment operation and fluctuations in environmental temperature can all cause thermal expansion or contraction of the base. Slight thermal deformation can cause positional deviations in the measuring probe, eventually leading to measurement errors. For industries with extremely high precision requirements such as aerospace and semiconductors, errors caused by thermal deformation may lead to product scrapping or performance degradation. Therefore, the thermal stability of the base is of vital importance.

Thermal imager: Visualizes the differences in thermal deformation

Thermal imagers can convert the temperature distribution on the surface of an object into visual images. By analyzing the temperature changes in different areas, they can visually present the thermal deformation situation. In the experiment, we selected granite and cast iron three-coordinate measuring machine bases of the same specification, simulated the heat generation during the operation of the equipment under the same environment, and used a thermal imager to record the temperature changes and thermal deformation processes of both.

Cast iron base: Significant thermal deformation and worrying stability

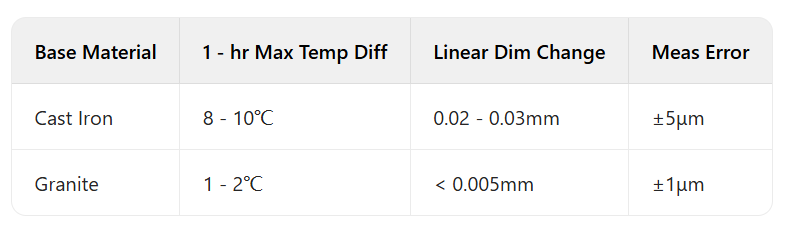

The thermal imaging image shows that after the cast iron base has been in operation for 30 minutes, there is a significant uneven distribution of surface temperature. Due to the uneven thermal conductivity of cast iron, the temperature in the local area of the base rises rapidly, and the difference between the highest and lowest temperatures can reach 8-10 ℃. Under the action of thermal stress, the cast iron base undergoes tiny deformations visible to the naked eye. It was detected by high-precision measuring equipment that the change in its linear size reached 0.02-0.03mm. This deformation would cause the measurement error to expand to ±5μm, seriously affecting the measurement accuracy. In addition, after the cast iron base stops running, the heat dissipates slowly and it takes as long as 1 to 2 hours to return to the initial state, which greatly limits the continuous operation capacity of the equipment.

Granite base: Excellent thermal stability ensures measurement accuracy

In sharp contrast, the granite base exhibits excellent thermal stability during operation. Thermal imaging images show that the surface temperature distribution is uniform. After one hour of operation, the maximum temperature difference on the base surface is only 1-2 ℃. This is attributed to the extremely low coefficient of thermal expansion of granite (5-7 ×10⁻⁶/℃) and its excellent uniformity of thermal conductivity. After testing, the linear dimensional variation of the granite base under the same working conditions is less than 0.005mm, and the measurement error can be controlled within ±1μm. Even after long-term continuous operation, the granite base can still maintain a stable shape, and after the operation stops, the temperature quickly returns to a stable state, providing a reliable reference for the next measurement.

Through the intuitive presentation and data comparison of the thermal imager, the advantage of granite in thermal stability is obvious. For manufacturing enterprises that pursue high-precision measurement, choosing a three-coordinate measuring machine with a granite base can effectively reduce measurement errors caused by thermal deformation and improve the accuracy and efficiency of product inspection. With the manufacturing industry moving towards high precision and intelligence, granite bases, with their outstanding thermal stability, are bound to become the preferred material for three-coordinate measuring machines and even more precision equipment, driving the quality control level of the industry to a new height.

Post time: May-13-2025