In the semiconductor manufacturing landscape, wafer cutting is a pivotal process demanding utmost precision. The choice of material for the equipment base significantly impacts performance. Let's compare granite with other common materials to see why it often comes out on top for wafer cutting equipment.

Granite: A Cut Above the Rest

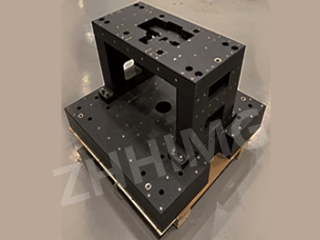

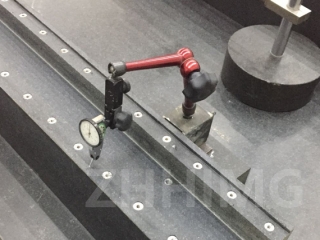

Stability: Granite, with a density around 3100 kg/m³ like ZHHIMG®'s offering, provides exceptional stability. Its stable structure minimizes vibrations during the wafer cutting process. In contrast, materials such as aluminum may be more prone to movement under the stress of high - speed cutting operations. This stability ensures that the cutting tool remains precisely positioned, resulting in accurate cuts and high - quality wafers.

Thermal Resistance: Granite has a low thermal expansion coefficient. In wafer cutting, where temperature fluctuations can occur due to the heat generated by the cutting process or the manufacturing environment, granite's thermal stability is a boon. It doesn't expand or contract significantly with temperature changes, maintaining the alignment of the cutting equipment. Metals like steel, on the other hand, can experience more substantial thermal expansion, potentially leading to misalignment and inaccurate cuts.

Vibration Damping: The natural vibration - damping properties of granite are remarkable. During wafer cutting, vibrations can cause the cutting tool to deviate from its intended path, leading to chipping or uneven cuts. Granite effectively absorbs and dissipates these vibrations, creating a smoother cutting operation. Materials such as plastic - based composites lack this inherent vibration - damping ability, making them less suitable for high - precision wafer cutting.

Comparing with Cast Iron

Cast iron has been a traditional choice for machine bases. However, it has its limitations compared to granite. While cast iron offers some stability, it is heavier than granite relative to its strength. This extra weight can pose challenges during equipment installation and movement. Additionally, cast iron is more susceptible to corrosion over time, especially in semiconductor manufacturing environments where chemicals may be present. Granite, being chemically inert, does not suffer from this issue, ensuring long - term durability and reliability.

The Case Against Marble

Some may consider marble as an alternative, but it falls short in many aspects for wafer cutting equipment. Marble has a lower density and is generally less stable than granite. It is also more porous, which can make it vulnerable to damage from moisture and chemicals in the manufacturing environment. In wafer cutting, where precision and durability are critical, marble's physical properties do not match up to the requirements as well as granite does.

In conclusion, when it comes to choosing a material for wafer cutting equipment bases, granite, particularly high - quality granite like that offered by ZHHIMG®, stands out. Its stability, thermal resistance, and vibration - damping capabilities make it the optimal choice for achieving the high precision required in semiconductor wafer cutting. While there are other materials available, granite's unique combination of properties gives it a clear edge in this demanding application.

Post time: Jun-03-2025