In both architectural construction and precision engineering, structural support elements play a decisive role in long-term stability, load-bearing performance, and dimensional integrity. While steel beams have long dominated conventional structural design, granite-based structural elements are increasingly evaluated in specialized applications where vibration control, thermal stability, and long-term accuracy are critical.

At the same time, the growing demand for heavy natural stone installations—particularly large-format countertops and engineered stone surfaces—has driven renewed attention to granite countertop support brackets and their structural design principles.

This article examines granite versus steel beams from a mechanical and application-driven perspective, while also exploring how structural concepts translate into practical support solutions for granite countertops and stone installations. Rather than focusing on architectural aesthetics, the discussion centers on material behavior, load paths, and stability under real-world conditions.

Understanding Structural Beams: Functional Requirements

A structural beam, regardless of material, must satisfy several fundamental requirements:

- Adequate load-bearing capacity under static and dynamic conditions

- Predictable deformation behavior under load

- Resistance to environmental influences such as temperature and humidity

- Long-term dimensional and structural stability

Material selection determines how effectively these requirements are met and how much additional engineering—such as reinforcement or isolation—is required to achieve reliable performance.

Steel Beams: Strength and Versatility

Steel beams are widely used due to their high tensile strength, ductility, and ease of fabrication. Standardized profiles allow engineers to design structures efficiently across a broad range of applications.

From a mechanical standpoint, steel offers excellent load-bearing capacity relative to its cross-sectional area. It performs well under tensile and bending loads and can accommodate significant deformation before failure, providing a high degree of structural safety.

However, steel beams also exhibit characteristics that limit their suitability in certain precision-oriented or stone-support applications. Steel has relatively low internal damping, allowing vibration to propagate efficiently through the structure. Its coefficient of thermal expansion is comparatively high, meaning temperature changes can lead to measurable dimensional variation.

Additionally, steel structures may contain residual stresses introduced during welding, rolling, or machining. Over time, stress relaxation can cause subtle geometric changes, which are acceptable in general construction but problematic in precision-sensitive systems.

Granite Beams: Mass, Stability, and Damping

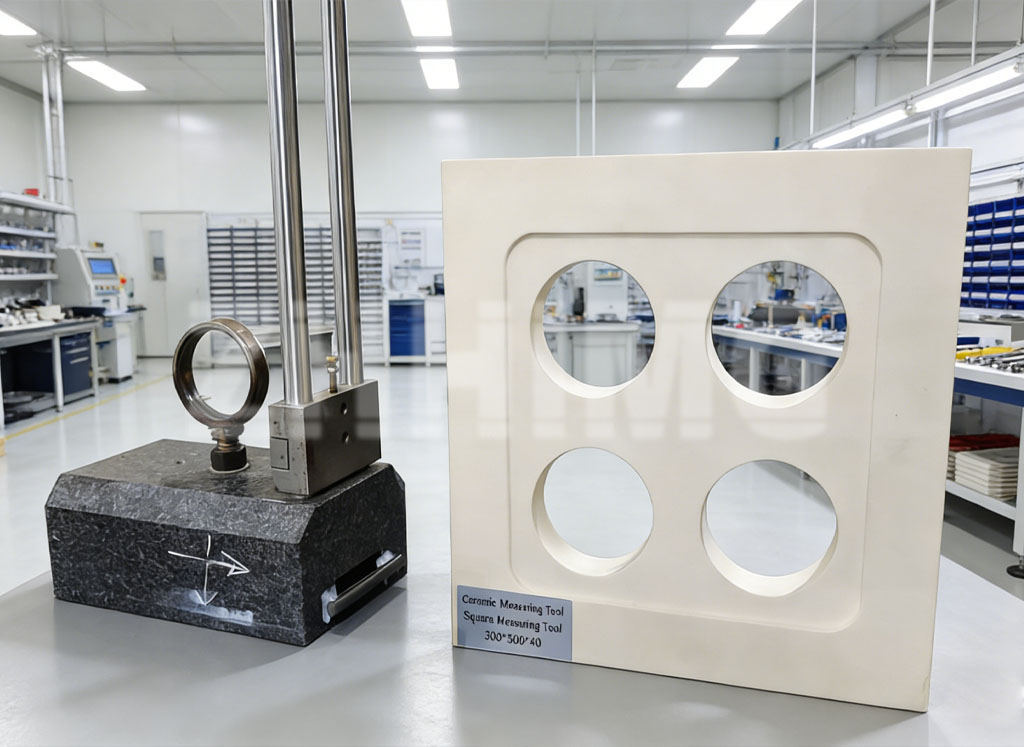

Granite is rarely considered a conventional beam material in mainstream construction, yet it offers unique advantages in specialized structural roles. High-density granite exhibits exceptional compressive strength, excellent vibration damping, and outstanding thermal stability.

Unlike steel, granite is isotropic and free from residual manufacturing stress. Under compressive loading, its deformation behavior is highly predictable and repeatable. These characteristics make granite particularly attractive in applications where long-term stability outweighs the need for tensile flexibility.

The high mass of granite beams contributes to natural vibration suppression, reducing resonance and minimizing the transmission of external disturbances. This property is especially valuable in precision equipment foundations, machine frames, and support structures for sensitive installations.

Granite’s limitations lie primarily in its brittle nature and lower tensile strength compared to steel. As a result, granite beams must be carefully engineered to avoid tensile stress concentrations and are typically used in compression-dominated load paths or in combination with steel reinforcement.

Granite vs. Steel Beams: Engineering Comparison

When comparing granite and steel beams, it is essential to evaluate performance in context rather than in isolation.

Steel beams excel in applications requiring high tensile strength, long spans, and structural flexibility. Granite beams, by contrast, are better suited for applications emphasizing mass, damping, and dimensional stability.

In vibration-sensitive environments, granite’s inherent damping often reduces the need for complex isolation systems. Steel structures frequently require additional damping treatments or isolation mounts to achieve comparable performance.

Thermally, granite responds more slowly to temperature fluctuations, reducing thermal gradients and associated deformation. Steel’s rapid thermal response can introduce alignment drift in precision installations.

From a lifecycle perspective, granite structures exhibit minimal aging effects, while steel structures may require ongoing inspection, corrosion protection, and stress management.

Structural Principles Applied to Granite Countertop Support

Granite countertops present a different but related structural challenge. Large stone slabs impose significant static loads, particularly at overhangs, cutouts, and unsupported spans.

Granite countertop support brackets apply beam principles on a smaller scale. Their purpose is to transfer load safely from the stone to the underlying cabinetry or wall structure while minimizing deflection and stress within the granite.

Steel is commonly used for countertop brackets due to its tensile strength and thin-profile capability. Properly designed steel brackets can provide strong support with minimal visual impact.

However, the interaction between steel brackets and granite slabs requires careful consideration. Differential thermal expansion, point loading, and vibration transmission can introduce localized stress in the stone if not properly managed.

Design Considerations for Granite Countertop Support Brackets

Effective granite countertop support brackets must address several key factors:

- Load distribution across a sufficient contact area

- Limitation of tensile stress within the granite slab

- Control of deflection under long-term static load

- Compatibility with stone thickness and material properties

In high-end or large-format installations, hybrid solutions are sometimes employed. These may include reinforced stone beams, concealed steel supports combined with stone ribs, or distributed support frames that reduce peak stress.

The design philosophy mirrors that of precision granite structures: prioritize compression, distribute loads evenly, and avoid stress concentrations.

Lessons from Precision Engineering

The use of granite in precision engineering offers valuable insights for architectural and interior applications. In metrology and machine design, granite structures are carefully engineered to work within their material strengths, avoiding tensile loading and leveraging mass and damping.

Applying similar principles to countertop support design improves long-term reliability and reduces the risk of cracking or sagging. Proper support spacing, adequate bracket depth, and attention to load paths are more critical than simply increasing material strength.

Long-Term Performance and Maintenance

Granite beams and granite-supported structures offer excellent durability when properly designed. Granite does not corrode, fatigue, or creep under normal conditions. Steel components, while strong, require corrosion protection and may transmit vibration or thermal movement into the supported stone.

In countertop applications, well-designed support brackets significantly extend service life by maintaining even load distribution and minimizing internal stress within the granite.

Conclusion

The comparison between granite and steel beams highlights the importance of aligning material properties with application requirements. Steel remains indispensable for long-span, tensile-dominated structures, while granite offers unmatched advantages in vibration damping, thermal stability, and long-term dimensional integrity.

In applications ranging from precision equipment foundations to granite countertop support brackets, understanding these structural principles enables more reliable, durable designs. By leveraging the strengths of each material—and applying engineering discipline to load management—designers and manufacturers can achieve superior performance across both industrial and architectural contexts.

Post time: Jan-28-2026