The food processing and packaging industry relies on a foundation of unyielding precision. Every component, from a high-speed filler nozzle to a complex sealing mechanism, must meet stringent dimensional tolerances to ensure product quality, minimize waste, and—most critically—guarantee consumer safety. This raises a fundamental question for quality control professionals: Is a precision granite platform suitable for component inspection in food machinery, and what role do hygiene requirements play?

The answer is a resounding yes, precision granite is exceptionally well-suited for the dimensional inspection of food machinery components, but its application environment demands careful consideration of hygiene standards.

The Case for Granite in Food-Grade Precision

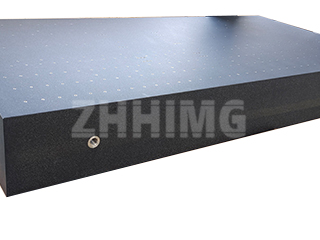

At its core, granite is the material of choice for metrology because of its inherent properties, which ironically align well with several non-food-contact hygiene principles. ZHHIMG®’s superior black granite, with its high density and low thermal expansion, offers a calibration benchmark that cast iron or stainless steel cannot match. It provides:

- Dimensional Stability: Granite is non-magnetic and highly resistant to rust and corrosion, key advantages in facilities with high humidity or frequent washdown cycles.

- Contaminant Inertness: Unlike metals, granite does not require corrosive rust-proofing oils and is inherently inert. It will not react with typical cleaning agents or food-related residues, provided the surface is properly maintained.

- Ultimate Flatness: Our platforms, achieving nanometer-level flatness and adherence to standards like ASME B89.3.7, are crucial for inspecting components like precision cutting blades, conveyor alignment rails, and sealing dies—parts where micron accuracy dictates food safety and operational integrity.

Navigating the Hygienic Design Imperative

While the granite surface plate itself is typically used in a segregated quality lab or inspection area, the inspection process supports compliance with sanitary guidelines like those set by 3-A Sanitary Standards or the European Hygienic Engineering & Design Group (EHEDG).

The critical hygiene concern for any inspection tool revolves around two principles: cleanability and non-harboring of bacteria. For precision granite in a food-adjacent environment, this translates into rigorous protocols for the end-user:

- Non-Porous Surface: ZHHIMG’s fine-grained granite is naturally low-porosity. However, adherence to strict cleaning practices with appropriate, non-acidic industrial cleaners is vital to prevent any staining or micro-residue build-up.

- Avoidance of Contact: The granite platform should not be used as a general workspace. Acids from certain food/drink spills can etch the surface, creating microscopic harbors for contamination.

- Ancillary Component Design: If the granite platform requires an attached stand or ancillary tooling (such as jigs or fixtures), these metallic components must be designed for hygienic zones—meaning they must be easily disassembled, smooth, non-absorbent, and free of crevices or hollow tubing where moisture or microbes could accumulate.

In conclusion, precision granite platforms are an invaluable asset for food machinery quality control, serving as the trusted reference that validates a machine’s ability to operate safely and effectively. ZHHIMG’s role, as a certified manufacturer (ISO 9001 and metrology standard compliant), is to provide a platform of unquestionable accuracy, enabling our food machinery clients to confidently certify that their components—and ultimately, their products—meet the global standard for safety and precision.

Post time: Oct-22-2025