In LCD/LED laser cutting production, downtime is a key factor affecting production efficiency and cost. The high-precision granite base, with its unique properties, can effectively reduce downtime and bring many advantages to production.

Outstanding stability and vibration resistance

Granite has a natural vibration-absorbing property, and its molecular structure can absorb and buffer the vibrations generated during the laser cutting process. When LCD/LED laser cutting is carried out, if the high-frequency vibration of the equipment (usually between 20 and 50Hz) is not effectively suppressed, it will lead to a decrease in cutting accuracy, cause defective or scrap products, and then require the machine to be shut down for recalibalation and parameter adjustment. The high-precision granite base can reduce the vibration amplitude by more than 60%, keeping the laser cutting head stable during high-speed operation, making the cutting edge smoother, significantly reducing cutting quality issues caused by vibration, and avoiding frequent shutdowns for adjustment.

Extremely low coefficient of thermal expansion

During the LCD/LED laser cutting process, heat is generated and the ambient temperature may also fluctuate, which poses a test to the thermal stability of the equipment base. Common materials have a high coefficient of thermal expansion and are prone to deformation when the temperature changes, which affects the cutting accuracy. The coefficient of thermal expansion of granite is only 1/20 that of steel. Even in an environment with a large temperature fluctuation range (such as -20℃ to 50℃), it can still stably maintain the positioning accuracy within ±2μm. This ensures that during long-term continuous cutting operations, there will be no frequent shutdowns to recalicalibrate the cutting path and position due to thermal deformation of the base, guaranteeing the consistency and stability of the cutting accuracy.

High wear resistance and long service life

The high-precision granite base has high hardness and strong wear resistance, with a Mohs hardness of 6-7, which is three times the wear resistance of ordinary steel. During the long-term and high-frequency operation of the laser cutting equipment, the surface of the base is not prone to wear. Compared with other base materials that are prone to wear and tear, granite bases do not require frequent repair or replacement due to surface wear, which extends the overall service life of the equipment and reduces the unplanned downtime for maintenance caused by base wear problems.

High-precision processing and adaptability

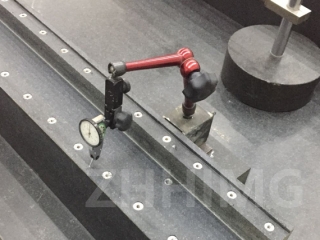

Modern high-precision granite bases adopt advanced processing techniques, such as five-axis CNC machining, etc. The precision indicators such as flatness and straightness are extremely high, and the flatness can reach ±0.5μm/m. This high-precision processing can provide an accurate installation reference for laser cutting equipment, making the assembly accuracy of each component of the equipment higher and the operation more stable. Meanwhile, the granite base can also be customized and processed according to the requirements of different laser cutting equipment, achieving perfect compatibility with the equipment and reducing operational failures and downtime for debugging caused by the mismatch between the base and the equipment.

Convenient maintenance and intelligent monitoring

Some high-precision granite bases are equipped with intelligent monitoring systems that can collect real-time data such as vibration, temperature and stress of the bases. Through the analysis of these data, potential failure risks can be predicted in advance, and maintenance can be arranged before faults occur, avoiding downtime caused by sudden failures. Moreover, the granite base itself has a stable structure and strong corrosion resistance. Its daily maintenance is relatively simple, without the need for complex maintenance procedures, further reducing maintenance downtime.

The high-precision granite base provides guarantees for the stable and efficient operation of LCD/LED laser cutting production in multiple aspects, significantly reducing downtime, enhancing production efficiency, and lowering the overall production cost. It is an ideal choice for modern LCD/LED laser cutting equipment. High-precision granite base: Significantly reduces the downtime of LCD/LED laser cutting

In LCD/LED laser cutting production, downtime is a key factor affecting production efficiency and cost. The high-precision granite base, with its unique properties, can effectively reduce downtime and bring many advantages to production.

Outstanding stability and vibration resistance

Granite has a natural vibration-absorbing property, and its molecular structure can absorb and buffer the vibrations generated during the laser cutting process. When LCD/LED laser cutting is carried out, if the high-frequency vibration of the equipment (usually between 20 and 50Hz) is not effectively suppressed, it will lead to a decrease in cutting accuracy, cause defective or scrap products, and then require the machine to be shut down for recalibalation and parameter adjustment. The high-precision granite base can reduce the vibration amplitude by more than 60%, keeping the laser cutting head stable during high-speed operation, making the cutting edge smoother, significantly reducing cutting quality issues caused by vibration, and avoiding frequent shutdowns for adjustment.

Extremely low coefficient of thermal expansion

During the LCD/LED laser cutting process, heat is generated and the ambient temperature may also fluctuate, which poses a test to the thermal stability of the equipment base. Common materials have a high coefficient of thermal expansion and are prone to deformation when the temperature changes, which affects the cutting accuracy. The coefficient of thermal expansion of granite is only 1/20 that of steel. Even in an environment with a large temperature fluctuation range (such as -20℃ to 50℃), it can still stably maintain the positioning accuracy within ±2μm. This ensures that during long-term continuous cutting operations, there will be no frequent shutdowns to recalicalibrate the cutting path and position due to thermal deformation of the base, guaranteeing the consistency and stability of the cutting accuracy.

High wear resistance and long service life

The high-precision granite base has high hardness and strong wear resistance, with a Mohs hardness of 6-7, which is three times the wear resistance of ordinary steel. During the long-term and high-frequency operation of the laser cutting equipment, the surface of the base is not prone to wear. Compared with other base materials that are prone to wear and tear, granite bases do not require frequent repair or replacement due to surface wear, which extends the overall service life of the equipment and reduces the unplanned downtime for maintenance caused by base wear problems.

High-precision processing and adaptability

Modern high-precision granite bases adopt advanced processing techniques, such as five-axis CNC machining, etc. The precision indicators such as flatness and straightness are extremely high, and the flatness can reach ±0.5μm/m. This high-precision processing can provide an accurate installation reference for laser cutting equipment, making the assembly accuracy of each component of the equipment higher and the operation more stable. Meanwhile, the granite base can also be customized and processed according to the requirements of different laser cutting equipment, achieving perfect compatibility with the equipment and reducing operational failures and downtime for debugging caused by the mismatch between the base and the equipment.

Convenient maintenance and intelligent monitoring

Some high-precision granite bases are equipped with intelligent monitoring systems that can collect real-time data such as vibration, temperature and stress of the bases. Through the analysis of these data, potential failure risks can be predicted in advance, and maintenance can be arranged before faults occur, avoiding downtime caused by sudden failures. Moreover, the granite base itself has a stable structure and strong corrosion resistance. Its daily maintenance is relatively simple, without the need for complex maintenance procedures, further reducing maintenance downtime.

The high-precision granite base provides guarantees for the stable and efficient operation of LCD/LED laser cutting production in multiple aspects, significantly reducing downtime, enhancing production efficiency, and lowering the overall production cost. It is an ideal choice for modern LCD/LED laser cutting equipment.

Post time: Jun-17-2025