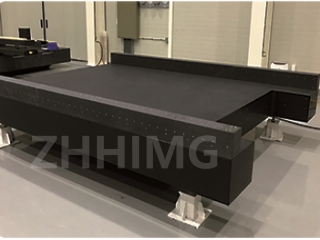

Granite surface plates are precision tools widely used in metrology, inspection, and machining applications. They are made from high-quality natural granite, prized for its stability, durability, and flatness. But just how accurate are these plates?

Natural Stability

Granite is formed over millions of years under extreme pressure and heat, resulting in a dense, fine-grained structure. This natural stability makes granite an ideal material for surface plates, as it resists deformation from temperature changes, humidity, and mechanical stress. In fact, granite has a low coefficient of thermal expansion, meaning it expands and contracts very little with temperature fluctuations. This property ensures that the plate's surface remains flat and true, even in challenging environments.

Precision Manufacturing

To achieve the highest levels of accuracy, granite surface plates undergo a rigorous manufacturing process. First, the granite block is carefully selected for its quality and consistency. Then, it is rough-cut to the desired size and shape. Next comes the lapping and polishing process, where the surface is gradually refined using abrasive materials. This meticulous process can achieve extremely low surface roughness and high flatness tolerances.

Accuracy Standards

The accuracy of granite surface plates is typically specified by their flatness tolerance. According to the American Society of Mechanical Engineers (ASME) B89.3.7 standard, surface plates are graded based on their flatness. The highest grade, AA, has the tightest tolerances, making it suitable for calibration laboratories and high-precision metrology. Grade A plates are commonly used in inspection areas, while Grade B plates, with slightly looser tolerances, may be found on shop floors.

For example, a 12" x 12" AA-grade granite surface plate may have a flatness tolerance of ±0.00005 inches across its entire surface. This level of precision allows for highly accurate measurements and calibrations of other tools and components.

Factors Affecting Accuracy

While granite surface plates are inherently accurate, several factors can affect their performance over time. Improper handling, such as dropping or subjecting the plate to excessive force, can cause chips or cracks that may impact flatness. Additionally, environmental factors like extreme temperature changes or high humidity levels can also influence the plate's accuracy. Regular cleaning and maintenance, as well as proper storage, are essential to preserve the plate's precision.

In conclusion, granite surface plates offer exceptional accuracy, making them a reliable choice for applications where precision is critical. Their natural stability, combined with precision manufacturing techniques, allows them to provide a stable and accurate reference surface for a wide range of industries, from aerospace and automotive to electronics and medical device manufacturing.

Post time: May-23-2025